EGR rate control method and device

A control method and EGR valve technology, applied in electrical control, engine control, fuel injection control, etc., can solve the problem of inability to meet the requirements of engine working conditions, inability to truly reflect EGR rate, low accuracy of exhaust gas volume and fresh air volume control and other problems, to achieve the effect of ensuring control accuracy, improving combustion phase, and realizing dynamic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

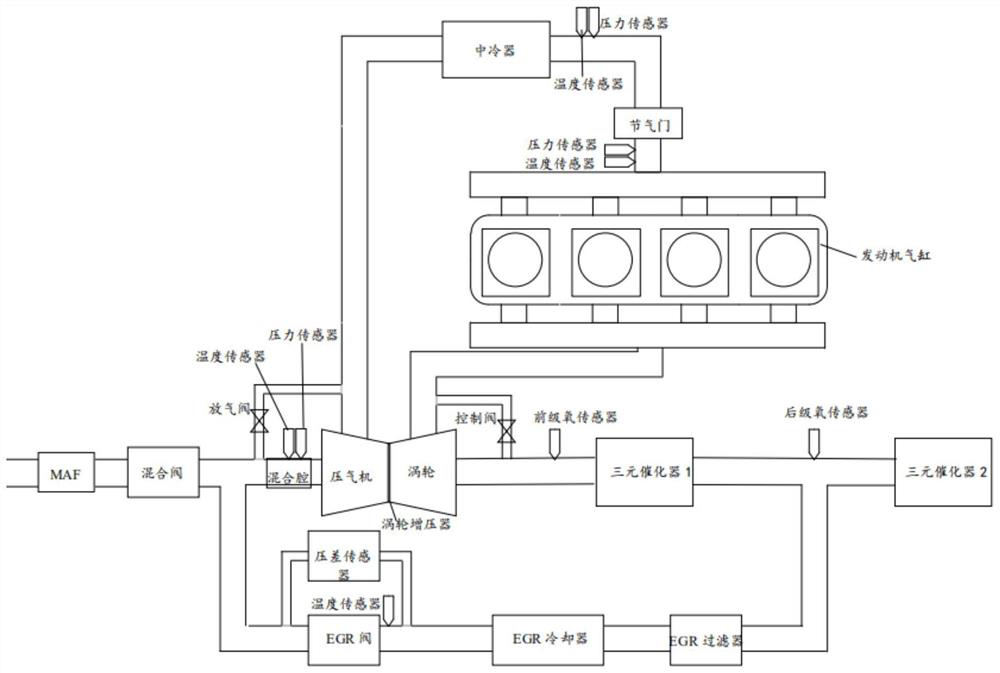

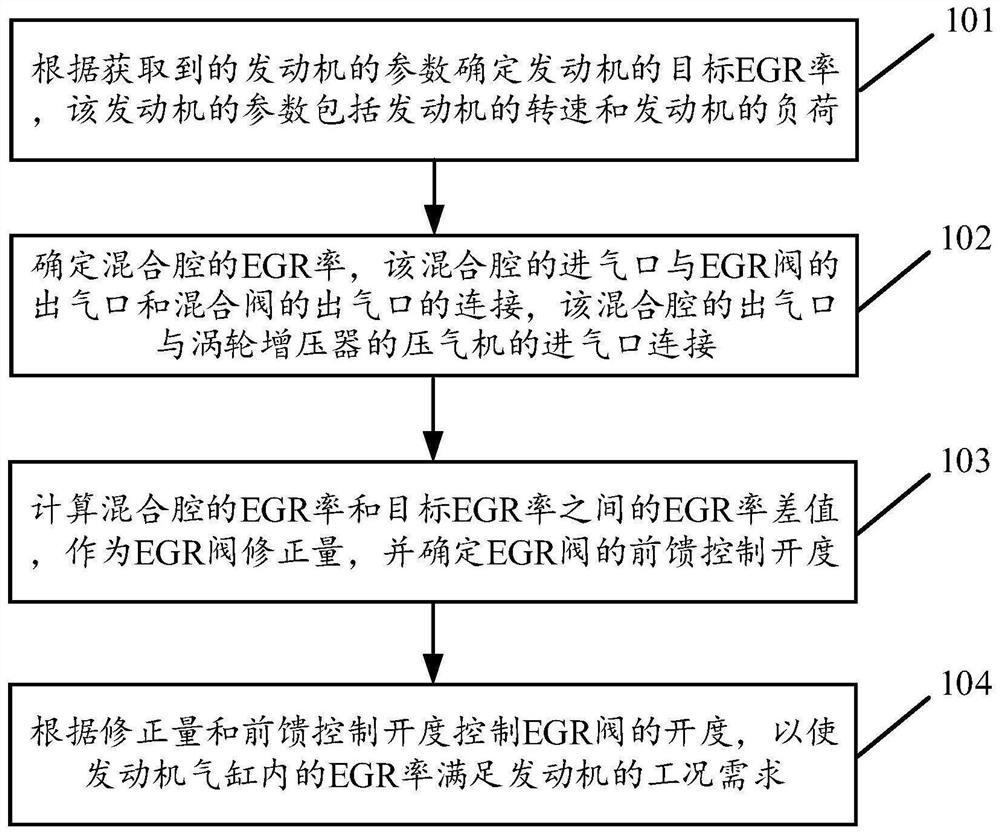

[0034] See figure 2 , figure 2 It is a flow chart of a control method of an EGR ratio disclosed in the embodiment of the present invention. in, figure 2 The control method of the described EGR rate is applicable to figure 1 The described engine system is described. like figure 2 As shown, the control method of the EGR rate can include the following operations:

[0035] 101. Determine the target EGR ratio of the engine based on the parameter of the acquired engine, the engine's parameters including the engine speed and the load of the engine.

[0036] In the embodiment of the present invention, the engine comprises any one of a gasoline engine or a diesel engine, and an embodiment of the present invention is not limited.

[0037] In the embodiment of the present invention, an EGR rate table is established in advance, which includes different engine speed and EGR ratio corresponding to the load of different engines, and different engines rotation and different engine loads correspon...

Embodiment 2

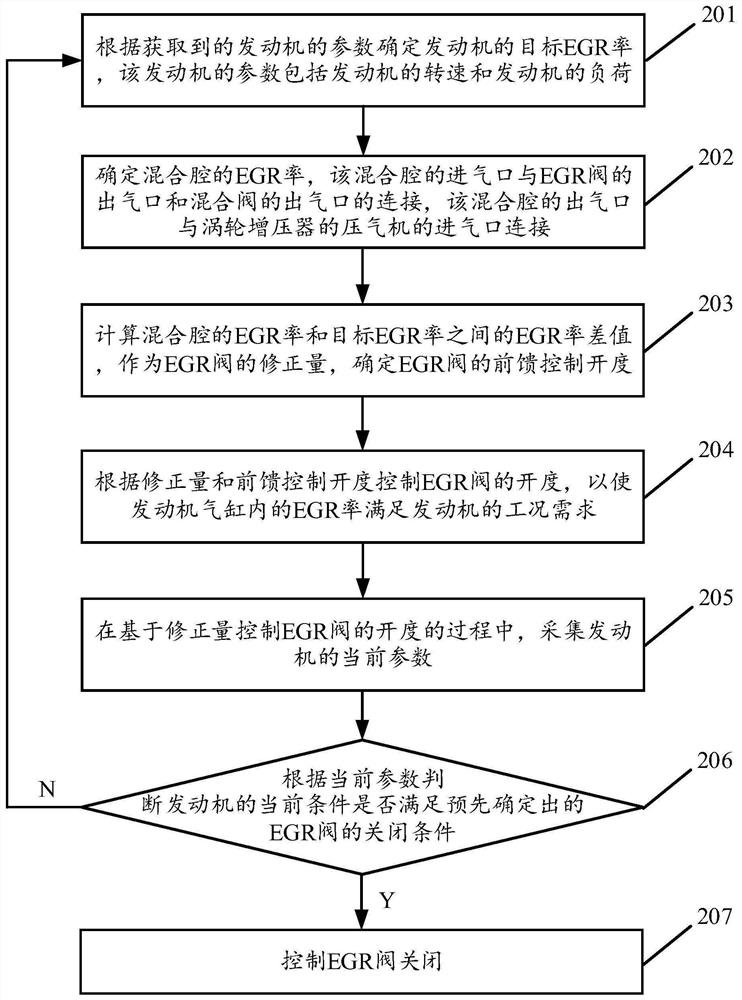

[0123] See image 3 , image 3 It is a flow diagram of another method of controlling the EGR rate according to the disclosed embodiment of the present invention. in, image 3 The method of controlling the EGR rate as described herein are applicable to figure 1 The engine system as described herein. like image 3 Shown, the EGR rate control method may include the following operations:

[0124] 201, determines a target EGR rate of the engine based on the parameter acquired engine parameters including engine speed and an engine load of the engine.

[0125] 202, it is determined the EGR rate of the mixing chamber, the compressor outlet connected to the inlet and outlet of the mixing chamber of the EGR valve and the mixing valve, the outlet of the mixing chamber with a turbocharger connected to the intake port.

[0126] 203, the difference between the calculated EGR rate EGR rate and the mixing chamber of the target EGR rate, the EGR valve as the correction amount.

[0127] 204, the correc...

Embodiment 3

[0144] See Figure 4 , Figure 4 It is a control device for an EGR rate disclosed in the embodiment of the present invention. Figure 4 The described EGR control is applied to figure 1 The described engine system is described. like Figure 4 As shown, the EGR control device can include:

[0145] Memory 401 stored in executable program code;

[0146] Processor 402 coupled to memory 401;

[0147] Further, it is also possible to include an input interface 403 and an output interface 404 coupled to the processor 402;

[0148] The processor 402 calls the executable program code stored in the memory 401 to perform the step of performing the control method of the EGR ratio described in the first embodiment or the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com