Comprehensive utilization and treatment process for solid waste coal

A treatment process and pretreatment technology, applied in the field of comprehensive utilization of solid waste coal, can solve the problems of land occupation and air pollution, and achieve the effects of saving resources, solving pollution problems, and increasing sintering strength and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

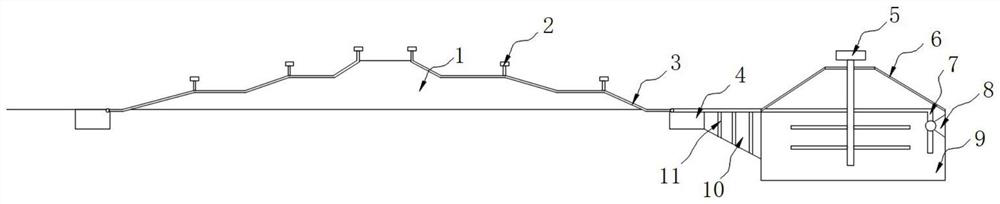

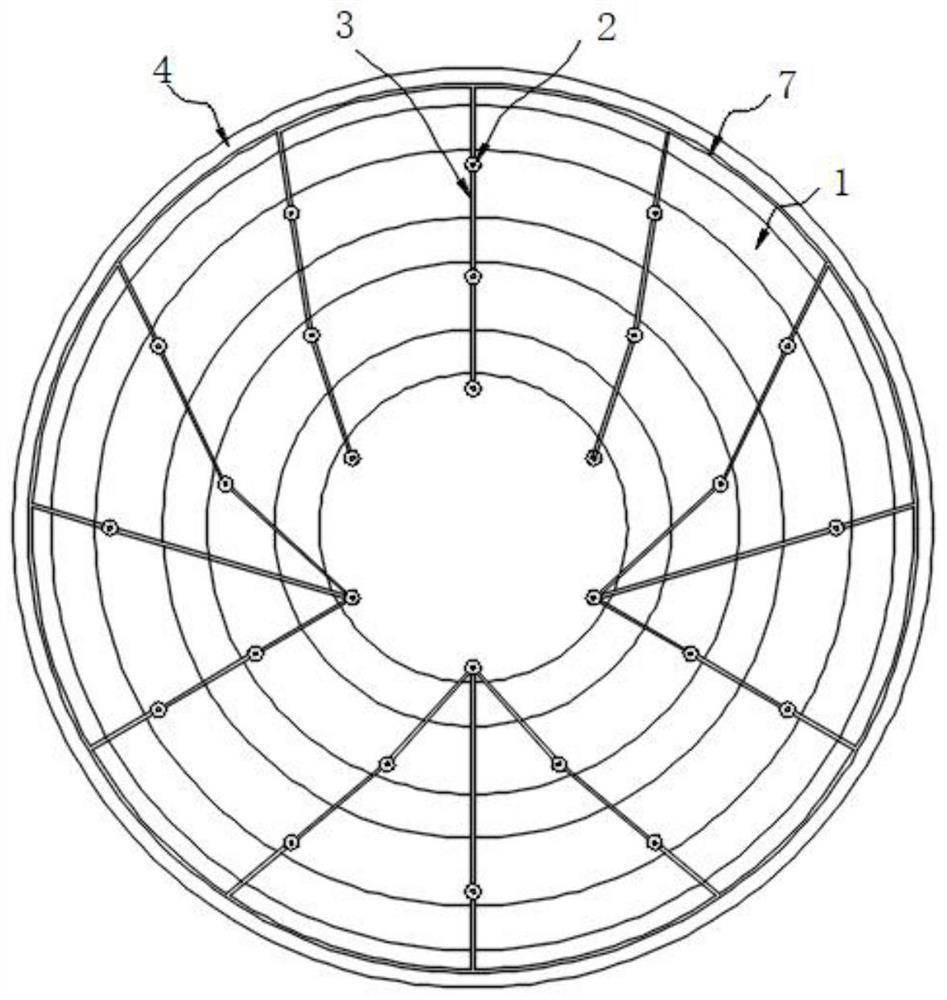

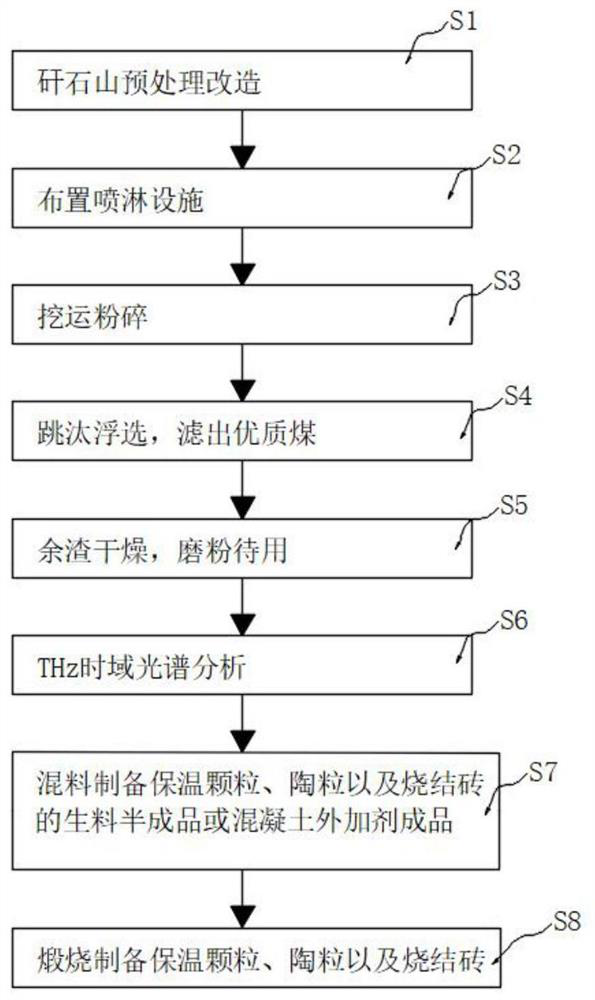

[0058]Example 1: Please refer to Figure 1-9 , a solid waste coal comprehensive utilization treatment process, comprising the following specific steps: S1: gangue hill pretreatment transformation; said S1, gangue hill 1 pretreatment transformation includes the following steps: S101, gangue hill 1 is terraced; Carry out layered and step-by-step transformation on gangue hill 1;

[0059] S102, setting up a drainage ditch 4 around the gangue hill 1; using an excavator to dig a drainage ditch, and hardening the drainage ditch to form a drainage ditch 4;

[0060] S103. Set up a reservoir 9 near the gangue hill 1, use an excavator to dig a water storage pit near the gangue hill 4, and perform hardening treatment to form the reservoir 9; the drainage ditch 4 is connected to the reservoir 9; S104, water storage A water treatment mechanism is set on the pool 9; in this embodiment, a mixer 5 is installed in the tank 9, and the mixer 5 is fixed on the top of the tank 9 through a bracket ...

Embodiment 2

[0071] Example 2: Please refer to Figure 1-9 , a solid waste coal comprehensive utilization treatment process, comprising the following specific steps: S1: pretreatment transformation of waste rock 1; said S1, pretreatment transformation of waste rock 1 includes the following steps: S101, terraced transformation of waste rock 1; The excavator carries out layered and step-by-step transformation on gangue hill 1;

[0072] S102, setting up a drainage ditch 4 around the gangue hill 1; using an excavator to dig a drainage ditch, and hardening the drainage ditch to form a drainage ditch 4;

[0073] S103. Set up a reservoir 9 near the gangue hill 1, use an excavator to dig a water storage pit near the gangue hill 1, and perform hardening treatment to form a reservoir 9; the drainage ditch 4 is connected to the reservoir 9; S104, water storage A water treatment mechanism is set on the pool 9; in this embodiment, a mixer 5 is installed in the tank 9, and the mixer 5 is fixed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com