A rotary tig welding torch for welding and repairing the inner wall of very small diameter pipes

A tube inner wall, extremely small technology, applied in the field of rotary TIG welding torch, can solve the problems that the water cooling gas supply device cannot be placed, cannot enter the ultra-thin pipe, and no water cooling scheme is given, so as to achieve good gas protection effect, good water cooling effect, The effect of effective air-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

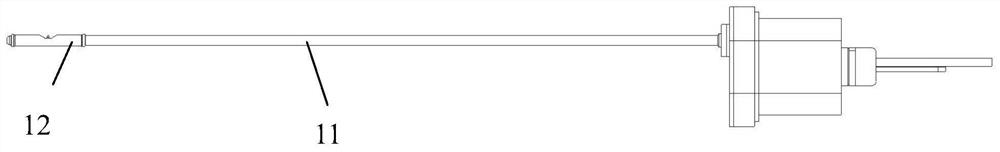

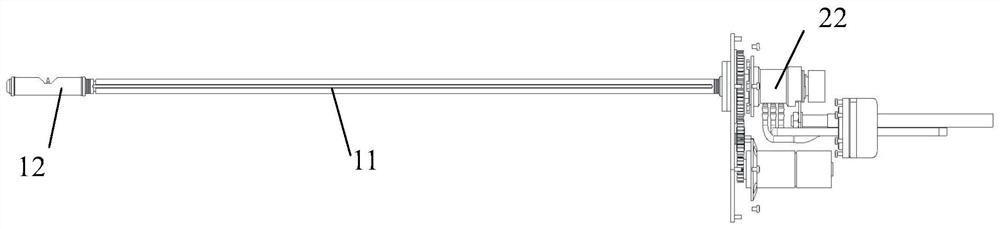

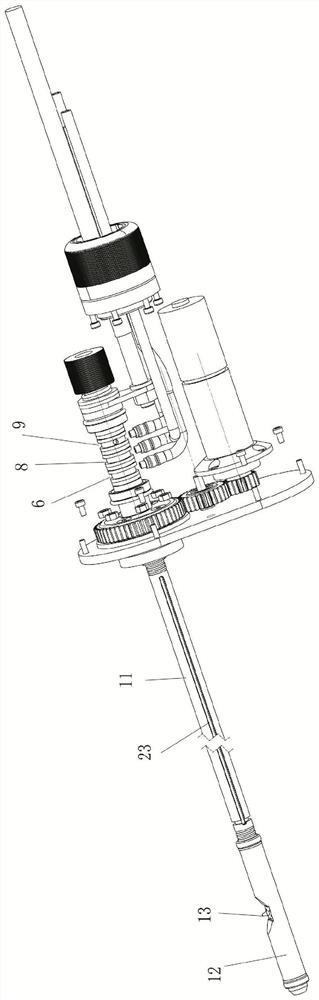

[0035] like Figure 1 to Figure 6 As shown, in this embodiment, a rotary TIG welding torch for welding and repairing the inner wall of a very small diameter pipe includes a long straight conductive shaft 11 , a tungsten electrode conductive rod 12 and a rotary drive device.

[0036] The long straight conductive shaft 11 and the tungsten electrode conductive rod 12 are made of metal materials, and the long straight conductive shaft 11 is connected with the tungsten electrode conductive rod 12 .

[0037] The rotary drive device includes a motor 1 and a gear set; in this embodiment, the welding torch further includes a housing with an accommodating cavity; the rotary drive device is located in the accommodating cavity of the housing. The gear set includes a first-stage cylindrical gear 3, a second-stage cylindrical gear 4 and a third-stage cylindrical gear 5 which are meshed in sequence; the motor 1 is connected with the first-stage cylindrical gear 3 through the electric flange ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com