Tube cutting machine

A pipe cutting machine and cutting mechanism technology, which is applied in metal processing and other directions, can solve the problems of low efficiency of the pipe cutting machine, achieve the effect of beautiful and consistent product appearance, stable clamping and rotation, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

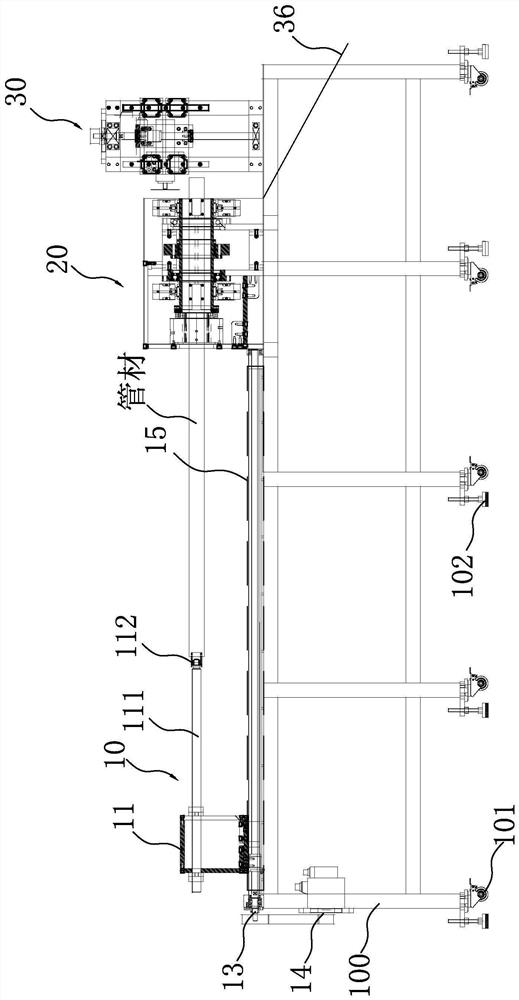

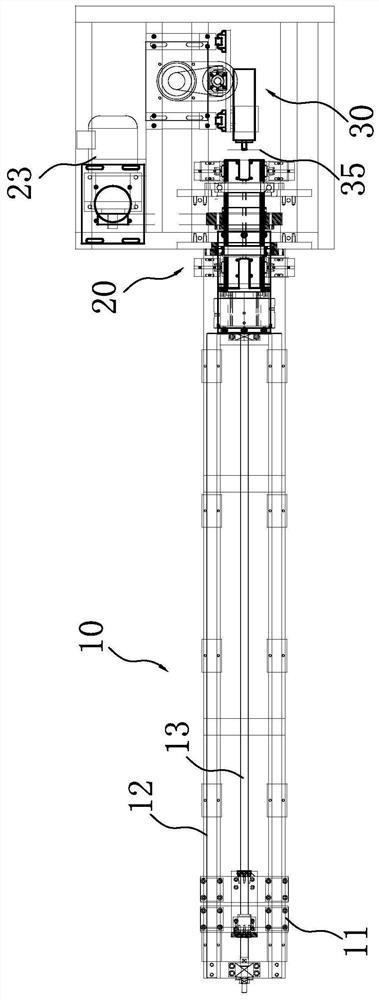

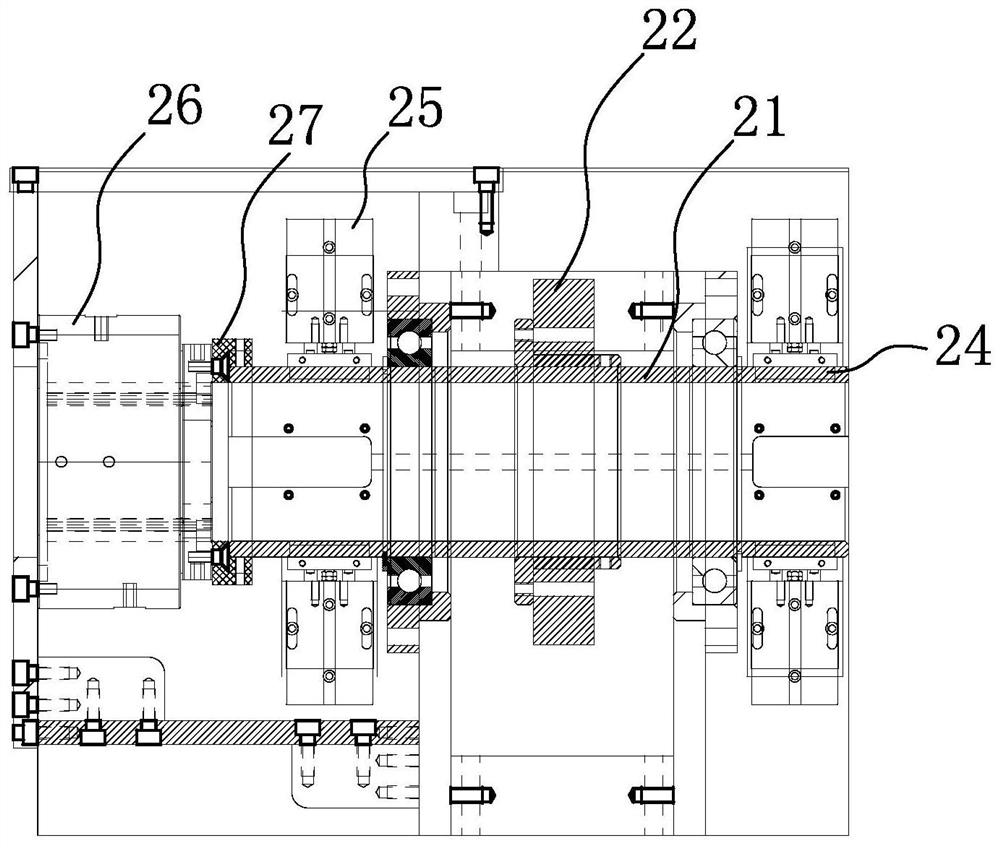

[0036] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a pipe cutting machine, including a frame 100, the frame 100 is provided with a feeding mechanism 10, a clamping and rotating mechanism 20, and a cutting mechanism 30 in sequence, and the feeding mechanism 10 includes a traversing bracket 11, and the traversing The traversing bracket 11 can be laterally slidably erected on the frame 100 through the traversing guide rail assembly 12, and a traversing screw assembly 13 for driving its movement is connected to the traversing bracket 11, and the traversing screw assembly 13 is transmission-connected to a The traverse motor 14 drives the traverse bracket 11 to reciprocate along the traverse guide rail assembly 12; the traverse bracket 11 is erected with a pole 111, and the end of the pole 111 is rotatably provided with a rotating sleeve 112, one end of the pipe to be processed is sleeved on the rotating sleeve 112;

[0037]The clamping and rotating mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com