Liquid crystal elastomer material based on liquid metal nano-droplets

A technology of liquid crystal elastomer and liquid metal, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve problems such as insufficient service life, and achieve the effects of excellent reversible deformation, excellent strain performance, and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: The specific preparation steps of the liquid crystal elastomer based on liquid metal nano-droplets are as follows:

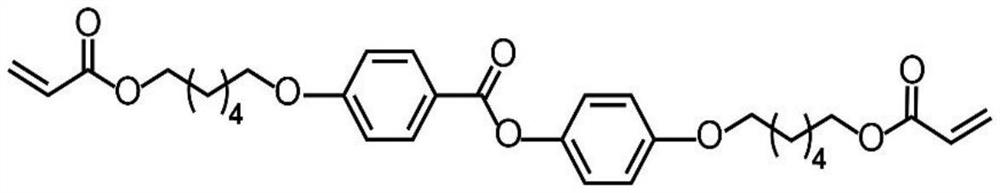

[0066] Weigh liquid crystal monomer Y2003 (592.5 mg, 1.1 mmol), chain extender 2,2'-oxybis(ethane-1-thiol) (138.2 mg, 1.0 mmol), cross-linking agent pentaerythritol tetrakis (3- Mercaptopropionate) (24.4mg, 0.05mmol) and liquid metal (39.7mg) were added to a 10mL brown inoculum bottle; measure and dissolve 6.00μL catalyst dipropylamine in dichloromethane (1.8mL), then add into the above-mentioned brown strain bottle; use a sonicator to sonicate for 1 h to mix the above mixture evenly; pour the resulting solution into a polytetrafluoroethylene (PTFE) mold (3cm long x 2cm wide x 1cm deep), Then put it in an oven at 40°C for 1.5h; then carefully take out the obtained pre-crosslinked LM-LCE-5 sample from the PTFE mold; cut it and stretch it to about 270% of its original strength, and Keep it fixed; put it in an oven and keep it at 40°C for 10 h...

Embodiment 2

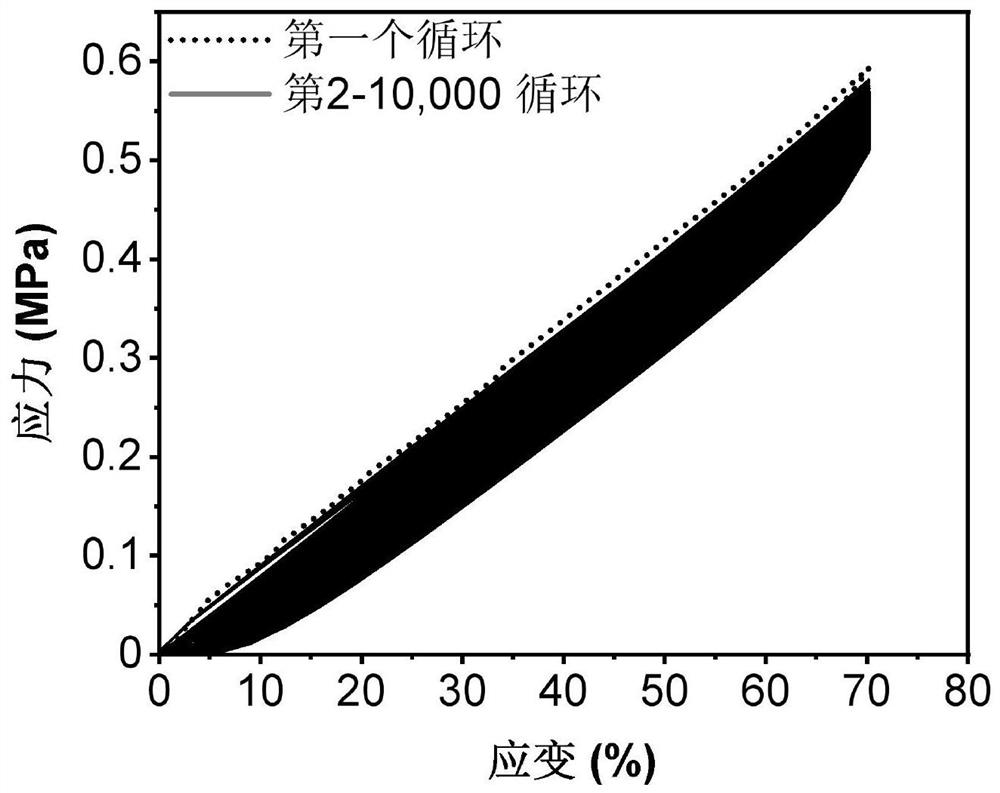

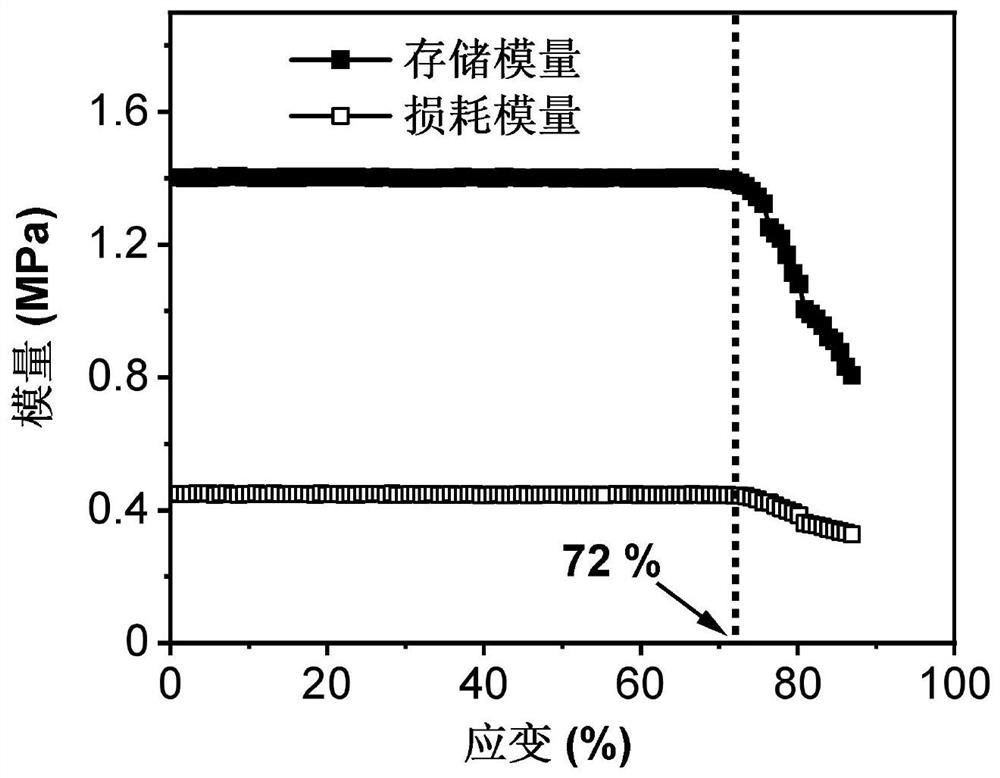

[0067] Example 2: Stress-strain, toughness, reversible deformation, maximum actuation stress, linear viscoelastic region, ultraviolet light drive, contraction force and self-repair test during heating process of the prepared liquid metal nano-droplet liquid crystal elastomer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com