Concrete-filled steel tube composite column and repairing method

A technology of concrete filled steel tube and repair method, which is applied to columns, pillars, piers and other directions, can solve the problems of environmental pollution, small earthquake magnitude, waste, etc., and achieves the effect of reducing dust pollution, improving seismic performance and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

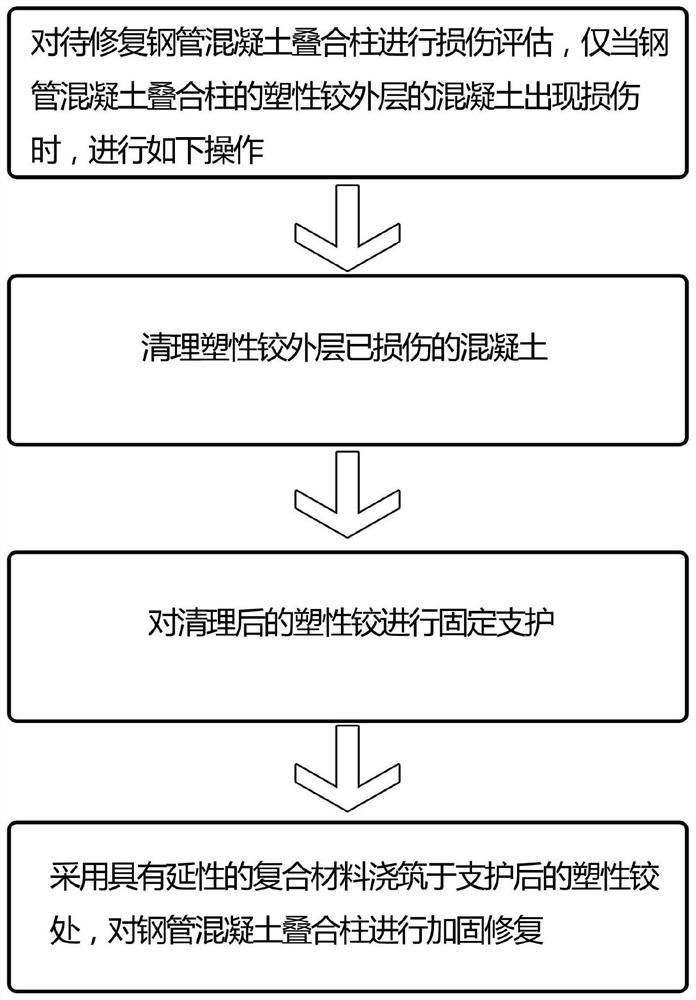

[0032] refer to figure 1 , the present invention provides a method for repairing concrete-filled steel pipe composite columns, which can be used for repairing and strengthening after earthquakes such as figure 2 For the concrete-filled steel tube composite column shown, the method includes:

[0033] Carry out damage assessment for the concrete-filled steel tube composite column to be repaired. Only when the concrete of the plastic hinge outer layer of the concrete-filled steel tube composite column is damaged, the following operations are performed:

[0034] Step 1: If image 3 As shown, cleaning the damaged concrete on the outer layer of the plastic hinge can clearly expose the position that needs to be repaired.

[0035] Step two: Figure 4 As shown, the cleaned plastic hinge is fixed and supported, and the fixed support adopts support parts and auxiliary materials to fix and support the cleaned plastic hinge to improve the repair ability.

[0036] Step 3: Use ductile c...

Embodiment 2

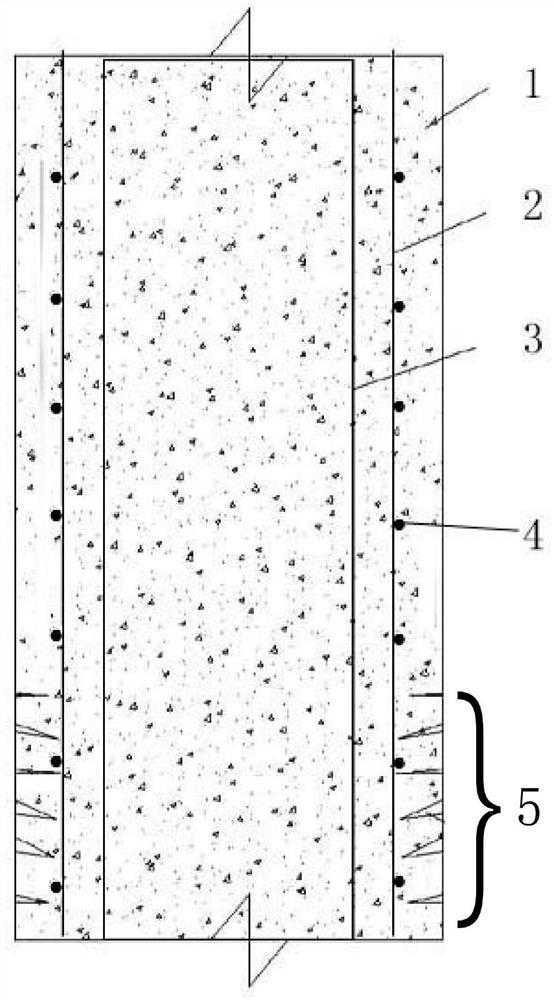

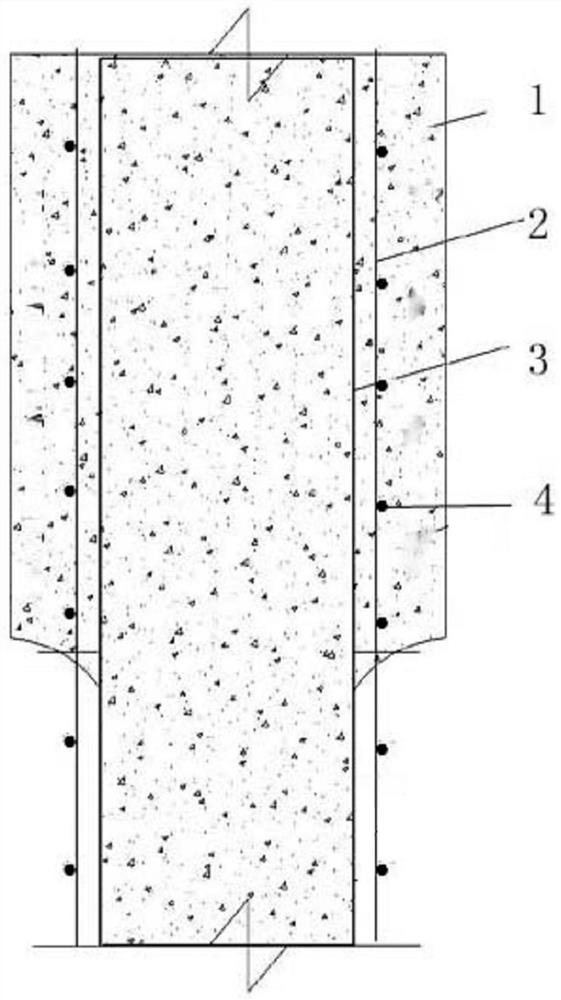

[0042] refer to Figure 5 , Figure 6 , the embodiment of the present invention provides a concrete-filled steel tube composite column, the steel pipe 3 outer circumference of the steel tube concrete composite column is poured with a concrete wrapping layer except for the plastic hinge 5 of the steel tube 3-concrete composite column, and the plastic hinge 5 places Coated with ductile composite material, the composite material is seamlessly connected with the concrete wrapping layer, effectively increasing the seismic performance of the concrete-filled steel tube composite column.

[0043] Specifically, engineering cement-based composite materials can be used as composite materials. The compressive strength of engineering cement-based composite materials is roughly 30-90 MPa, the compressive strain is higher than that of ordinary concrete, and its bending resistance is also better than that of ordinary cement-based materials. It has a strong ability to control the development ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com