Temperature-pressure coupling bidirectional electromagnetic loading dynamic compression-shear experimental device and testing method

A technology of experimental device and temperature measuring device, which is applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/compression, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

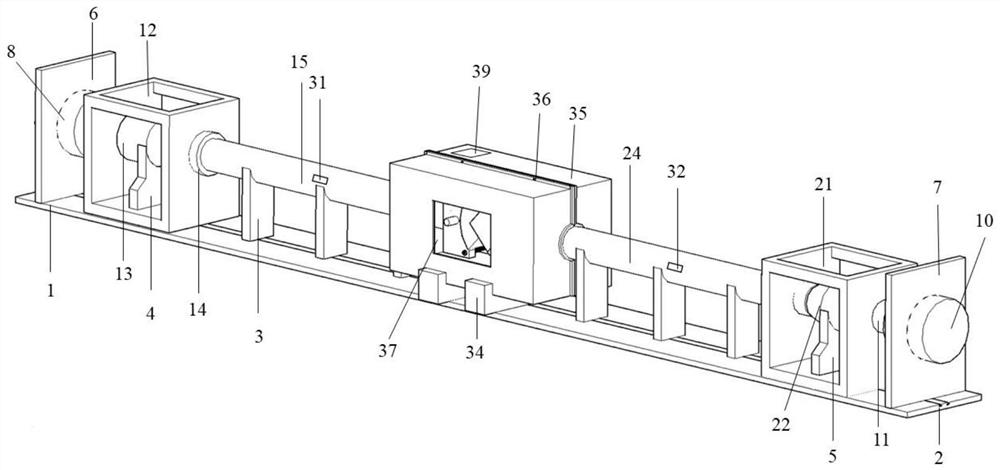

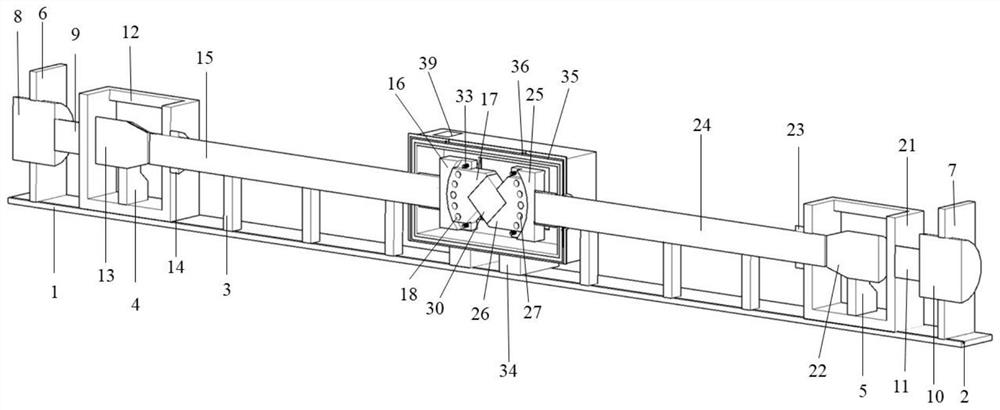

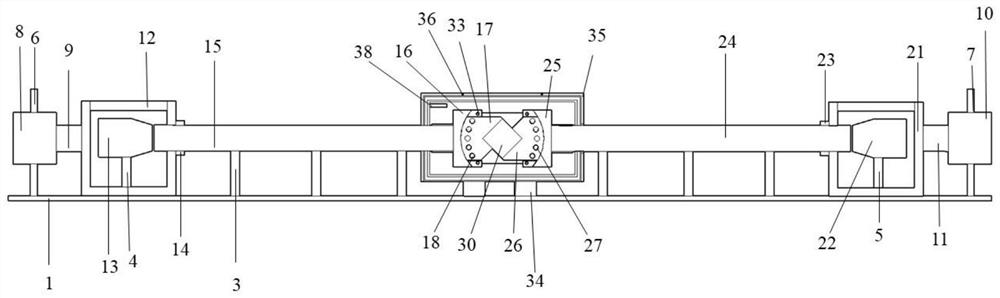

[0055] Place the left servo-controlled loading cylinder support base 6, the left loading frame 12, the loading rod support base 3, the right loading frame 21 and the right servo-controlled loading cylinder support base 7 from left to right on the support platform in sequence according to actual needs 1, the left servo control loading cylinder 8 is fixed on the left servo control loading cylinder support base 6, the right end surface of the left piston rod 9 is freely attached to the left end surface of the left loading frame 12, and the left electromagnetic pulse generator 13 Place it on the support base 4 of the left electromagnetic pulse generator, place the left electromagnetic pulse generator support base 4 and the left electromagnetic pulse generator 13 in the left loading frame 12, put the TC21 titanium alloy with a length of 2000 mm and a diameter of 50 mm on the left side The loading rod 15 is placed on the loading rod support base 3, the left loading rod 15 is parallel...

Embodiment 2

[0061] Place the left servo-controlled loading cylinder support base 6, the left loading frame 12, the loading rod support base 3, the right loading frame 21 and the right servo-controlled loading cylinder support base 7 from left to right on the support platform in sequence according to actual needs 1, the left servo control loading cylinder 8 is fixed on the left servo control loading cylinder support base 6, the right end surface of the left piston rod 9 is fixed on the left end surface of the left loading frame 12, and the left electromagnetic pulse generator 13 is placed on On the left electromagnetic pulse generator support base 4, the left electromagnetic pulse generator support base 4 and the left electromagnetic pulse generator 13 are placed in the left loading frame 12, and a TC21 titanium alloy left loading rod with a length of 2000 mm and a diameter of 50 mm is placed 15 is placed on the supporting base 3 of the loading rod, the loading rod is parallel to the axis d...

Embodiment 3

[0073] Such as Figure 7 As shown, place the left servo-controlled loading cylinder support base 6, the left loading frame 12, the loading rod support base 3, the right loading frame 21 and the right servo-controlled loading cylinder support base 7 from left to right according to actual needs. On the support platform 1, the left servo-controlled loading cylinder 8 is fixed on the left servo-controlled loading cylinder support base 6, the right end surface of the left piston rod 9 is freely attached to the left end surface of the left loading frame 12, and the left electromagnetic pulse The generator 13 is placed on the left electromagnetic pulse generator support base 4, the left electromagnetic pulse generator support base 4 and the left electromagnetic pulse generator 13 are placed in the left loading frame 12, and the TC21 titanium with a length of 3000 mm and a diameter of 75 mm The alloy left loading rod 15 is placed on the loading rod support base 3, the left loading rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com