System and method for positioning damage of HDPE (High-Density Polyethylene) film of refuse landfill

A landfill and positioning method technology, applied in the field of landfill HDPE film damage positioning system, can solve the problems of heavy manual workload, reduce missed detection rate, gas leakage, etc., achieve short detection cycle and reduce missed detection Efficient and time-sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

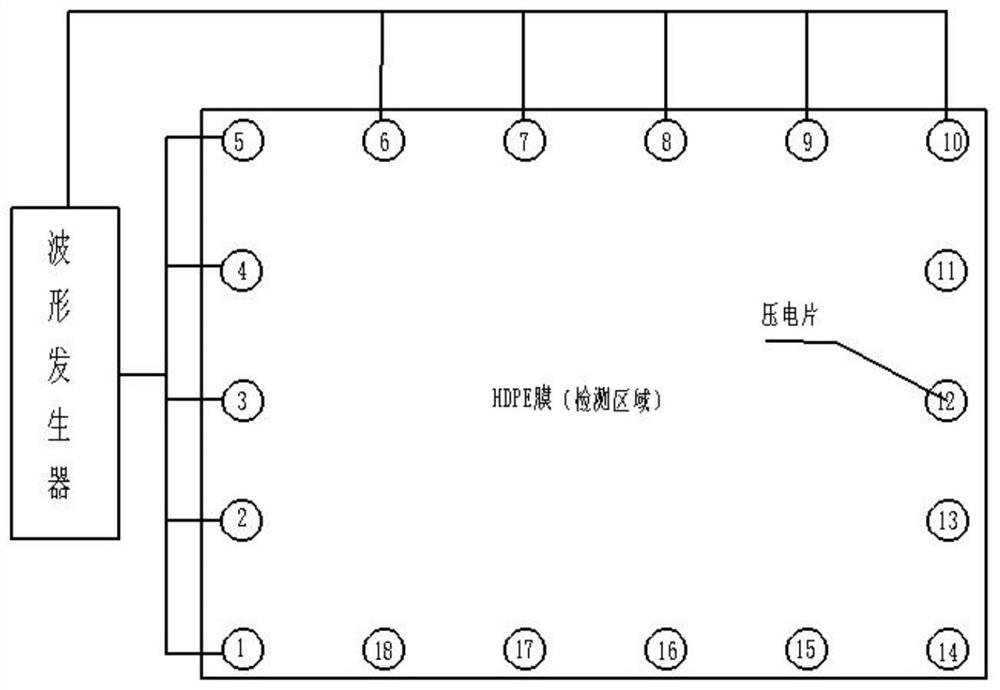

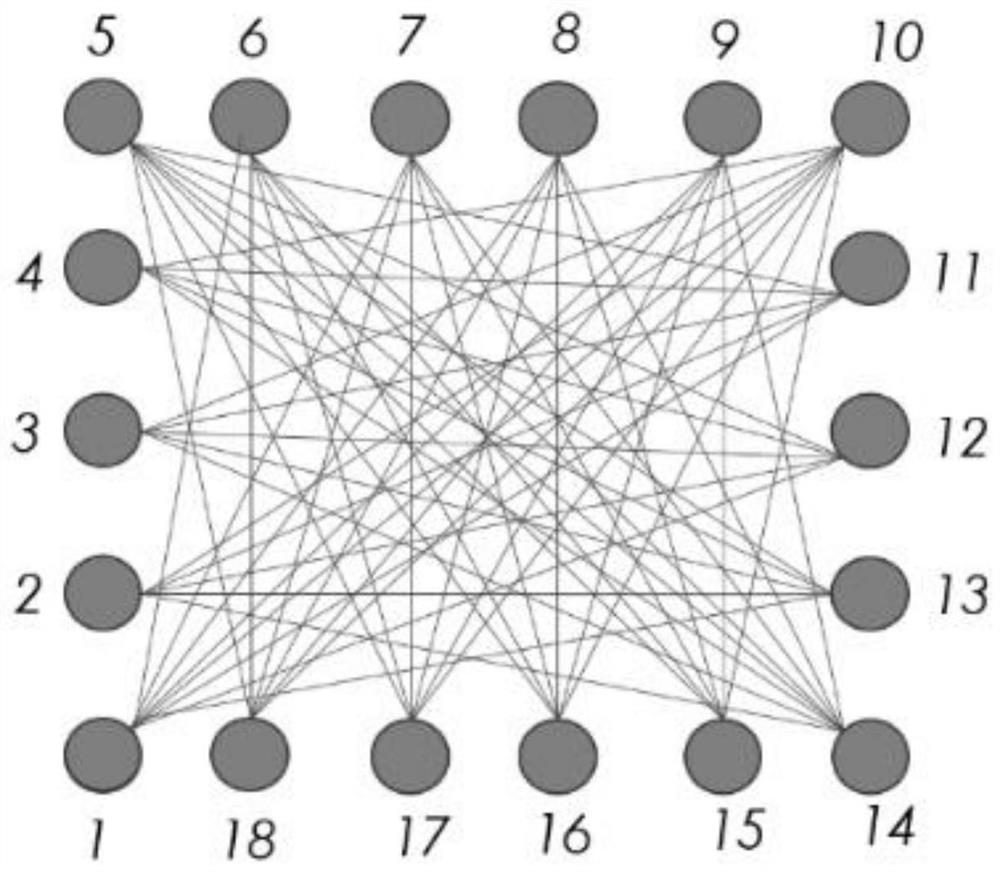

[0027] The following will introduce the HDPE film damage detection system involved in the patent of the present invention from three aspects of function, composition and working principle through the examples and in conjunction with the accompanying drawings, and further describe the technical solution of the present invention in detail.

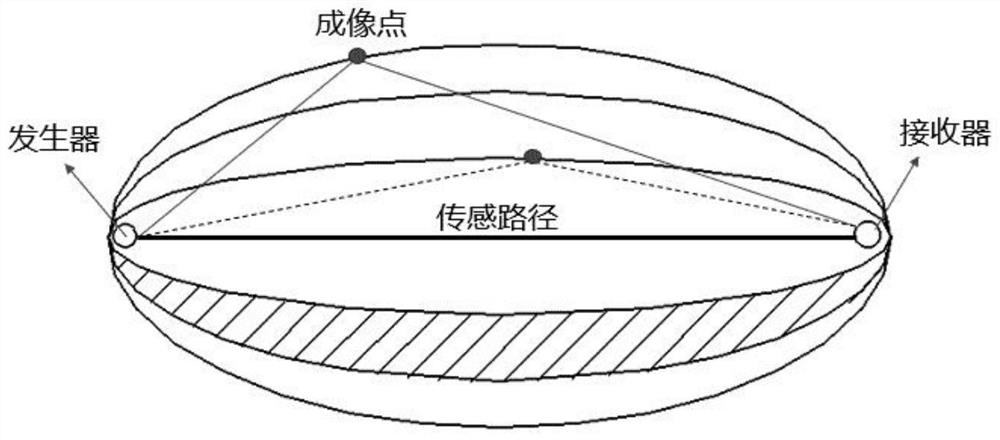

[0028] The technical scheme of the invention is to detect the damaged position of the HDPE film by collecting ultrasonic parameters. The key point is to use the rectangular piezoelectric sheet laid on the HDPE film to use the ultrasonic scattering characteristics when there is no damage, and combine wavelet transform and probability damage imaging to realize the HDPE film damage location in the landfill. Moreover, the ultrasonic waves used in the present invention scatter when they pass through the damage site, and have the characteristic that the closer the damage is to the sensing path, the more serious the energy attenuation is, thereby re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com