Automatic batching method for mineral powder production based on vanadium-titanium slag component characteristics and application

A technology for vanadium-titanium slag and slag powder, applied in the field of building materials, can solve the problems of difficulty in meeting the activity requirements of S75 grade slag powder, poor use effect, long time consumption, etc. The effect of efficient prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

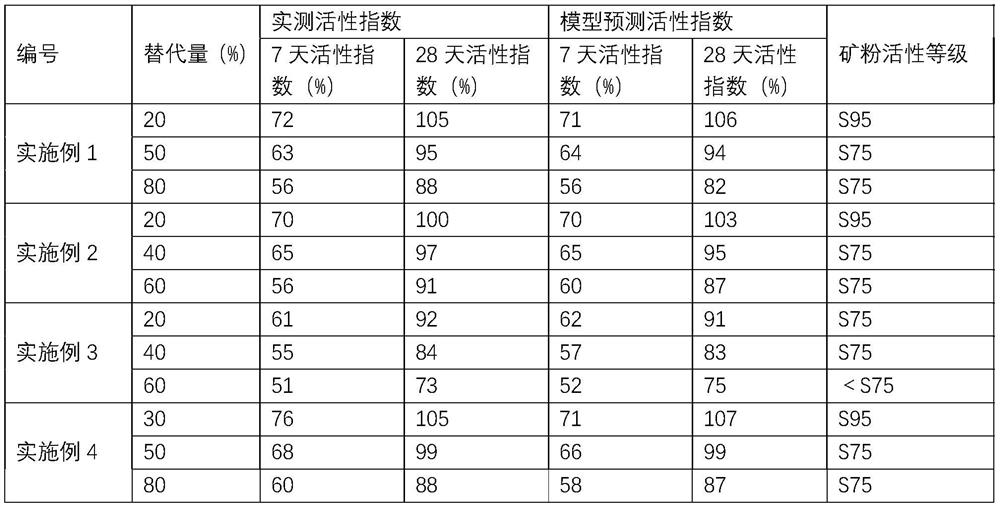

Embodiment 1

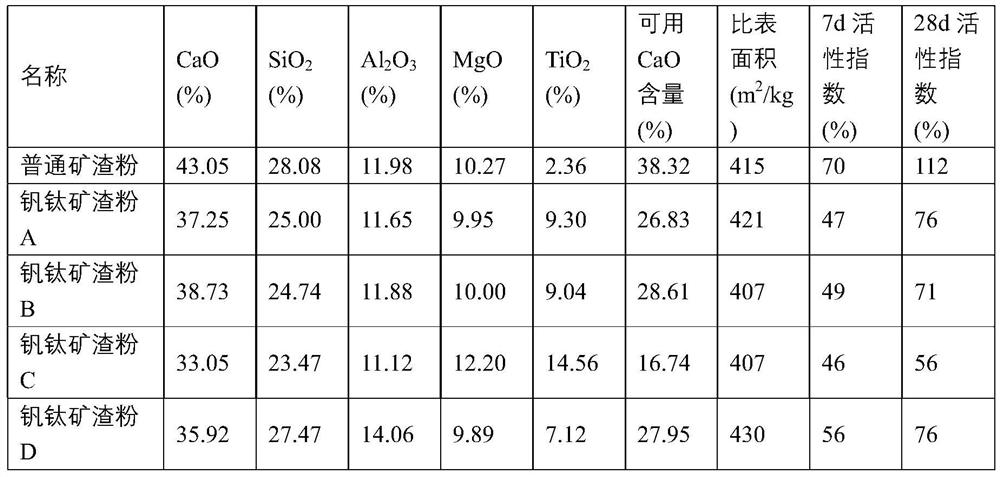

[0048] This embodiment provides a kind of method that utilizes different amounts of vanadium-titanium slag powder A to replace common slag to prepare slag, specifically as follows:

[0049] (1) Calculate the available CaO content according to the chemical composition data in Table 1:

[0050] Available CaO content = total CaO content in raw slag - 1.12 x total TiO in raw slag 2 Content = 26.83%

[0051] (2) The replacement amount of ordinary slag powder replaced by vanadium-titanium slag powder A is 20%, 50% and 80% respectively, according to the specific surface area and available CaO content of vanadium-titanium slag powder A in Table 1, according to the relationship model established respectively Calculate the 7-day activity index (A7) and 28-day activity index (A28) that it can achieve, and predict the activity level of the prepared mineral powder.

[0052] When the replacement amount of vanadium-titanium slag powder A is 20%,

[0053] A7=-18.620+0.649×(aCaO)-0.262×(P)+...

Embodiment 2

[0062] The present embodiment provides a kind of method that utilizes different amounts of vanadium-titanium slag powder B to replace common slag to prepare slag, specifically as follows:

[0063] (1) Calculate the available CaO content according to the chemical composition data in Table 1:

[0064] Available CaO content = total CaO content in raw slag - 1.12 x total TiO in raw slag 2 Content = 28.61%

[0065] (2) The replacement amount of ordinary slag powder replaced by vanadium-titanium slag powder B is 20%, 40% and 60% respectively, according to the specific surface area and available CaO content of vanadium-titanium slag powder B in Table 1, according to the relationship model established respectively Calculate the 7-day activity index (A7) and 28-day activity index (A28) that it can achieve, and predict the activity level of the prepared mineral powder.

[0066] When the replacement amount of vanadium-titanium slag powder B is 20%,

[0067] A7=-18.620+0.649×(aCaO)-0.2...

Embodiment 3

[0076] The present embodiment provides a kind of method that utilizes different amounts of vanadium-titanium slag powder C to replace common slag to prepare slag, specifically as follows:

[0077] (1) Calculate the available CaO content according to the chemical composition data in Table 1:

[0078] Available CaO content = total CaO content in raw slag - 1.12 x total TiO in raw slag 2 Content = 16.74%

[0079] (2) The replacement amount of vanadium-titanium slag powder C replacing common slag powder is 20%, 40% and 60% respectively, according to the specific surface area and available CaO content of vanadium-titanium slag powder C in Table 1, according to the relationship model established respectively Calculate the 7-day activity index (A7) and 28-day activity index (A28) that it can achieve, and predict the activity level of the prepared mineral powder.

[0080] When the vanadium-titanium slag powder C substitution amount is 20%,

[0081] A7=-18.620+0.649×(aCaO)-0.262×(P)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com