Swim suit

A swimsuit, polyurethane elastic technology, applied in protective clothing, special outerwear, knitting, etc., can solve the problems of low water retention rate and low waterproof performance, and achieve the effect of low water retention rate, high water resistance, and easy swimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

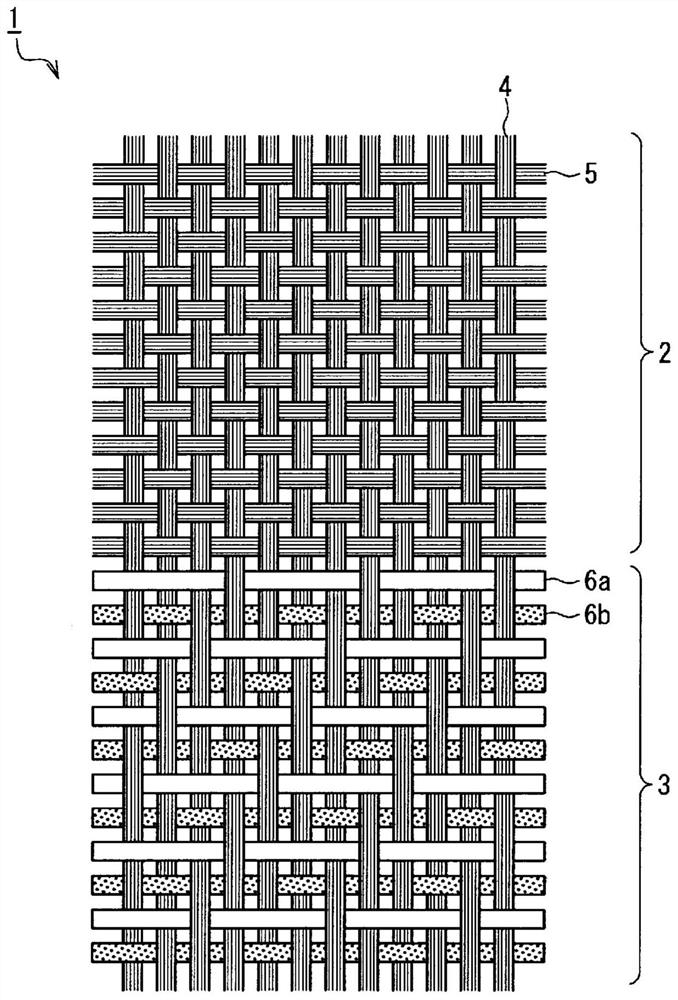

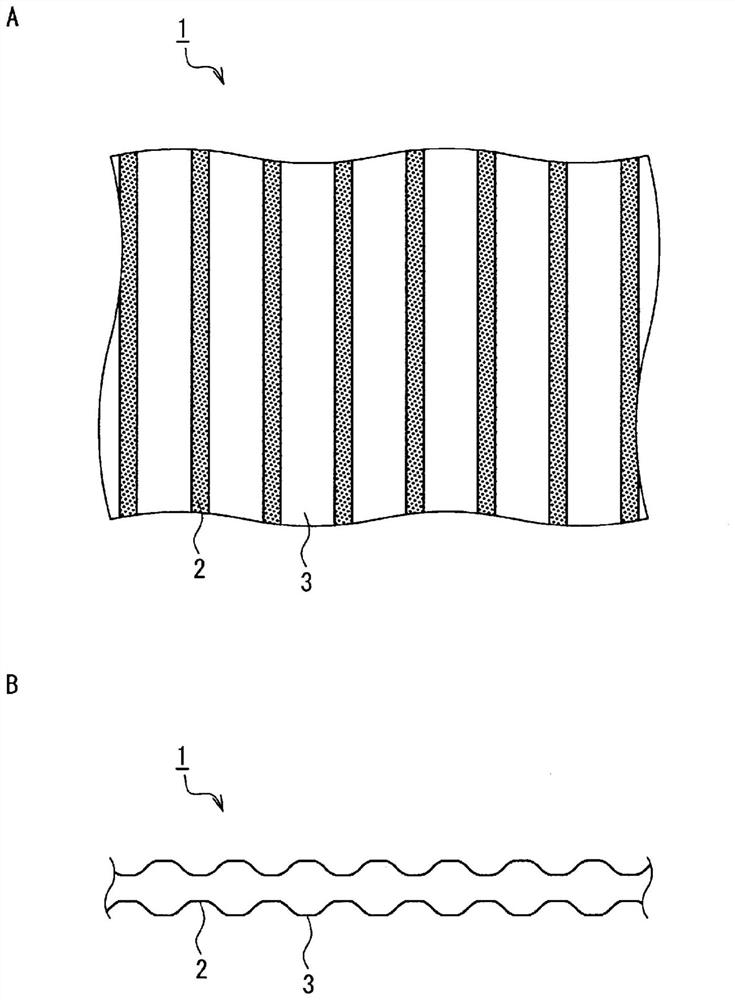

[0158] Yarn A is used for the warp yarn, yarn B is used for the weft yarn, and yarn C is used for the weft yarn. figure 1 The stretch fabric 1 shown alternately repeats plain weave portions 2 with double weft portions 3 . In the obtained fabric, nylon contained 66% by mass and polyurethane contained 34% by mass. The fabric is refined, intermediately fixed, dyed, and dried according to conventional methods. The obtained fabric was dipped in the following waterproof formulation, wrung out at 50% with a pickup, and then dried in a pin tenter set at a temperature of 130°C. Next, dry heat treatment was performed for 1 minute in a pin tenter set at a temperature of 170° C. to obtain a processed fabric of Example 1. The resulting processed cloth exhibited a high degree of water repellency, and a fabric cloth having a low water retention rate and exhibiting excellent water repellency was obtained.

[0159] · FX-ML (Kyosun Kasei Co., Ltd. fluorine-based waterproofing agent): 100g / L ...

Embodiment 2

[0167] Use yarn D for the warp and yarn E for the weft to make a plain weave fabric. Weaving nylon is 70%, polyurethane is the fabric of 30%, implements dyeing process and water-repellent process similarly to embodiment 1, and making warp density is 205 / 2.54cm, and weft density is 200 / 2.54cm, and per unit area The mass is 95g / m 2 fabric. The obtained processed fabric has high stretchability, good adhesion to human skin, high water repellency, and low water retention and excellent water repellency. The results are summarized in Table 1.

Embodiment 3

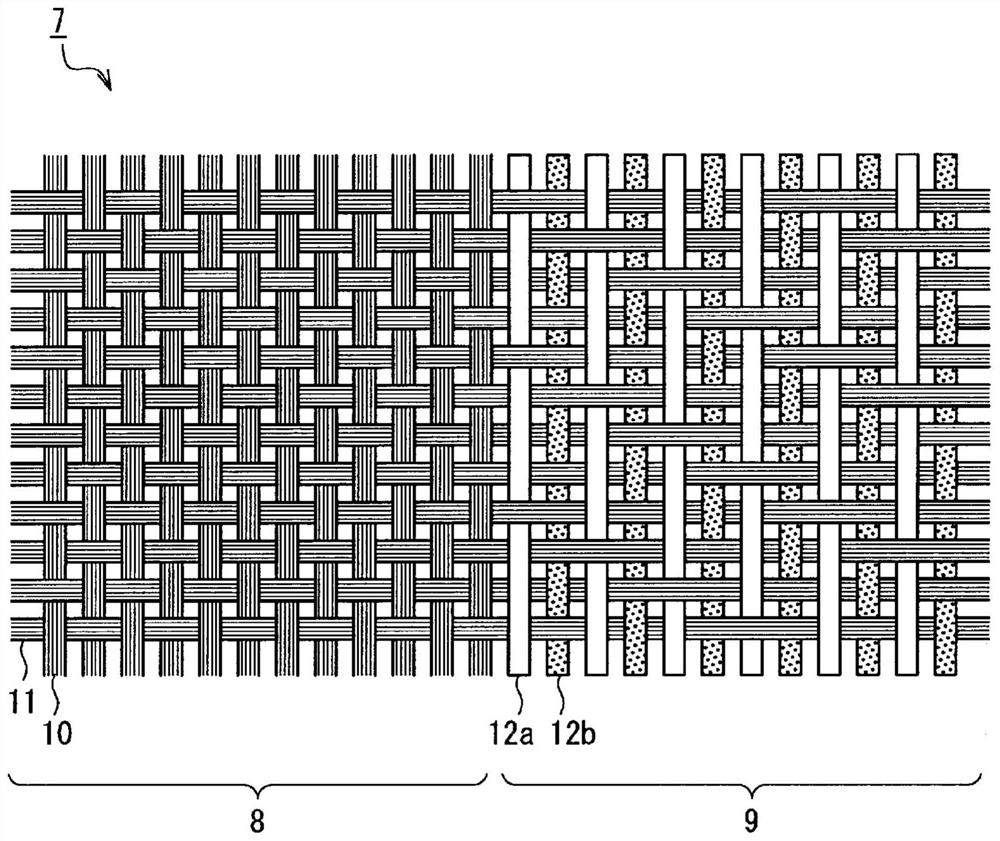

[0180]Use the fabric cloth of embodiment 1 and the fabric cloth of embodiment 2 to sew Figure 7 Men's swimsuits are shown for swimming competitions. The fabric cloth of Example 1 is a fabric in which the plain weave portion and the double weft portion are alternately repeated in the striped portion 24, and the striped portion 24 is arranged in the height direction of the human body. The plain weave fabric cloth of Example 2 is the plane portion 25 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com