Preparation process of sealing ring with embedded rib ring

A preparation process and sealing ring technology, which is applied in the field of preparation process of sealing rings embedded with ribs, can solve the problems of low strength, poor hardness of embedded objects, and poor sealing effect, so as to maintain stability, not easy to melt or deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

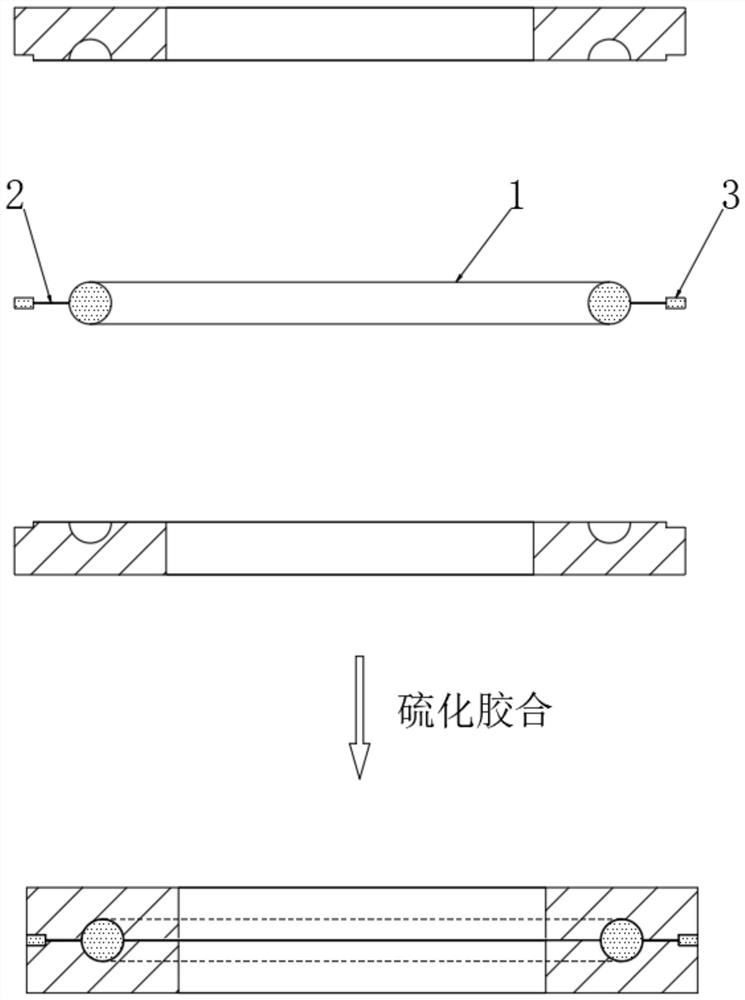

[0055] see figure 1 , a preparation process for a sealing ring with an embedded rib ring, comprising the following steps:

[0056] S1. Divide the sealing ring into two mutually symmetrical half circles in the radial direction, and then cast the half circles through the mold;

[0057] S2. Excavating an embedded groove at one of the ends of the half circle, and then inlaying a pretreated embedded rib ring on the embedded groove;

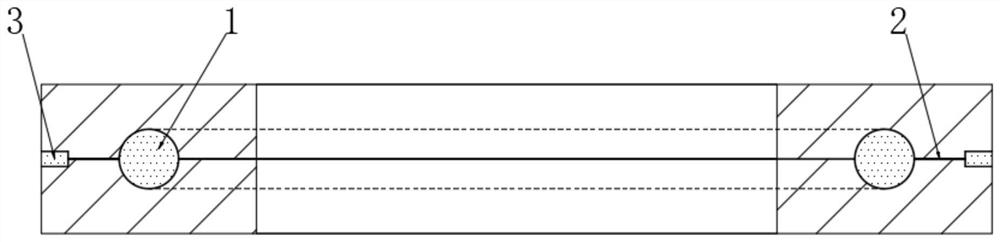

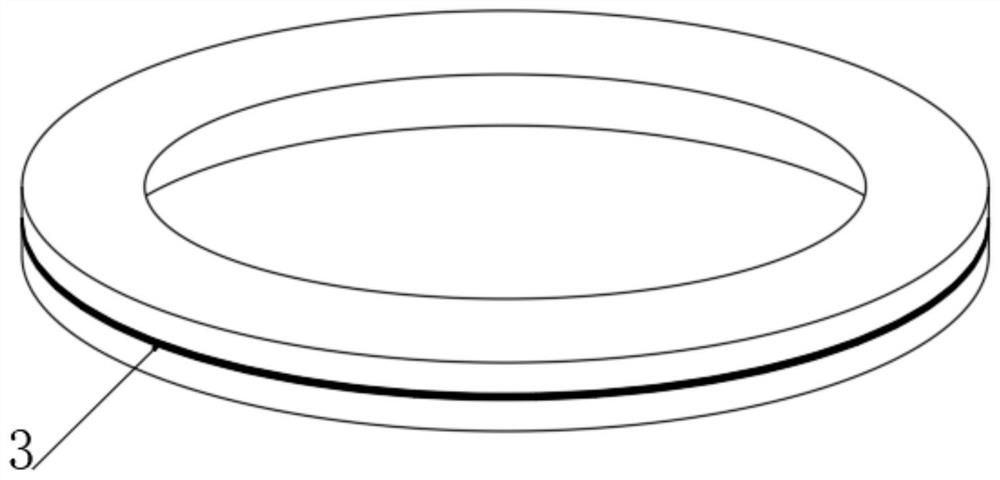

[0058] S3. Then align the inner embedding groove on the other half circle with the inner bead ring, make the two fit together, and vulcanize and glue them together to make the two into one, as Figure 2-3 , to complete the production of the sealing ring.

[0059] see Figure 4 , the inner rib ring includes a central liquid storage collar 1, a liquid sealing drum ring 2 connected to the outer end of the central liquid storage collar 1, and an outer color film 3 connected to the end of the liquid sealing drum ring 2 away from the central liquid storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com