Sewage treatment equipment for biomass degradation

A kind of sewage treatment equipment and biomass degradation technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, centrifugal separation water/sewage treatment, etc., can solve the problem of long natural sedimentation time of sewage and slow formation of mud cake , Persistent odor and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

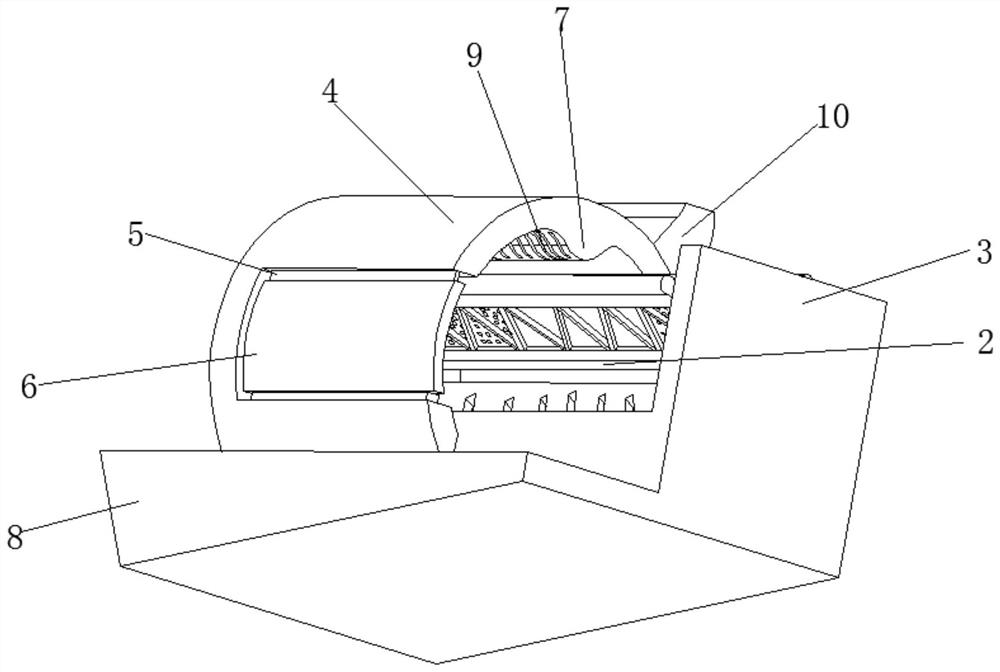

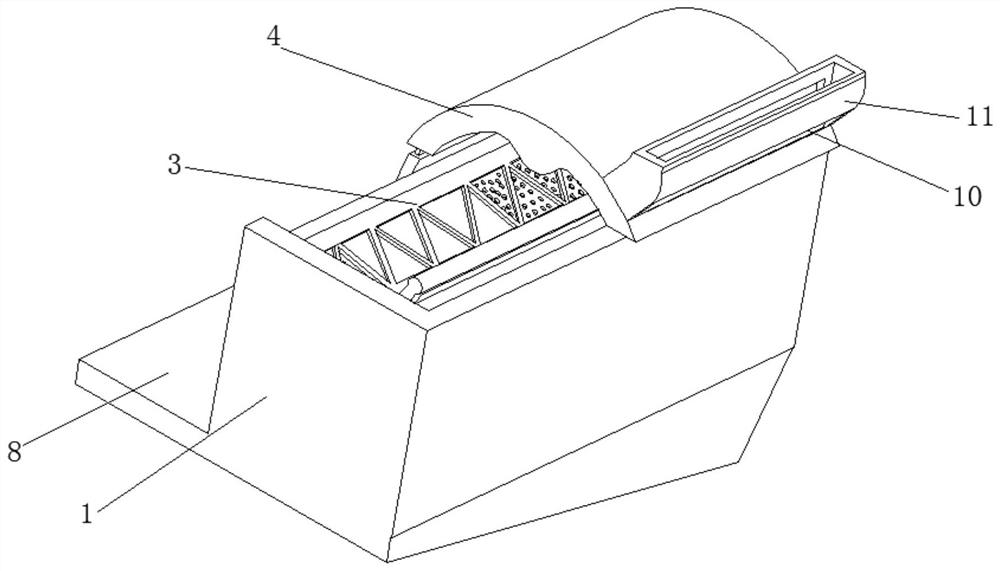

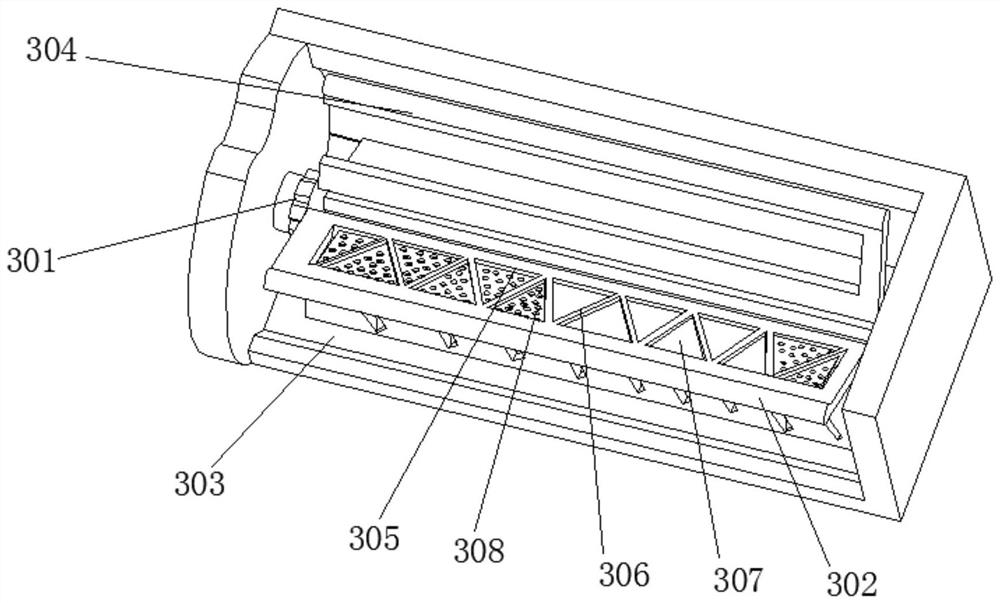

[0032] see Figure 1-4 , the present invention provides a technical solution: a sewage treatment equipment for biomass degradation, comprising a processing box 1, the inner surface of the processing box 1 is rotatably connected with a rotating main shaft 2, and the outer surface of the rotating main shaft 2 is fixedly connected with a separation mechanism 3, and the rotating The outer surface of the main shaft 2 is rotatably connected with an arc-shaped machine cover 4, the outer surface of the arc-shaped machine cover 4 is slidingly connected with the inner surface of the processing box 1, and the outer surface of the arc-shaped machine cover 4 is provided with a sliding groove 5, and The inner surface is slidingly connected with a connecting mechanism 6, the inner surface of the arc-shaped machine cover 4 is fixedly connected with a connecting channel 7 above the separation mechanism 3, the surface of the connecting channel 7 is evenly provided with a groove 9, and the bottom...

Embodiment 2

[0040] see Figure 5 The present invention provides a technical solution: the beating mechanism 8 includes a connection box 801, the top of the connection box 801 communicates with the bottom of the processing box 1, and the inner surface of the connection box 801 is rotatably connected with a plurality of drive shafts 802.

[0041] The outer surface of the driving shaft 802 is fixedly connected with a beating plate 803 , and the outer surface of the beating plate 803 is uniformly provided with ventilation holes 804 . After filtering, the rubbish to be molded is compacted downwards, and the vent hole 804 arranged above the board surface can also leave a gap when ventilating, so as to avoid a large amount of rubbish sticking to the bottom of the board surface.

[0042] In the above-mentioned embodiment two:

[0043] Between the processing box 1 and the connection box 801, there is a switchable through groove. After the sewage is discharged from the equipment after classificati...

Embodiment 3

[0045] see Figure 6-7 , the present invention provides a technical solution: the connecting mechanism 6 includes an arc-shaped sliding plate 601, the outer surface of the arc-shaped sliding plate 601 is slidingly connected with the inner surface of the sliding groove 5, and the bottom of the arc-shaped sliding plate 601 is movably connected with a U-shaped collector The box 602, the left side of the U-shaped collection box 602 and the left side of the arc-shaped sliding plate 601 are both provided with a single slot 603.

[0046] The inner surface of the U-shaped collection box 602 is rotatably connected with a retractable shaft 604 , and the outer surface of the retractable shaft 604 is wound and connected with a collection bag 605 . The outside of the collection bag 605 is provided with enough screening holes for solid-liquid separation, and after collecting the garbage, the inner volume of the collection bag 605 can be controlled by pulling the collection bag 605 on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com