Addition type flame-retardant silicone rubber and preparation method thereof

A silicone rubber and addition molding technology, applied in the rubber field, can solve problems such as restricting the development of liquid silicone rubber, and achieve the effects of non-toxic and environmentally friendly raw materials, reduced flammability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

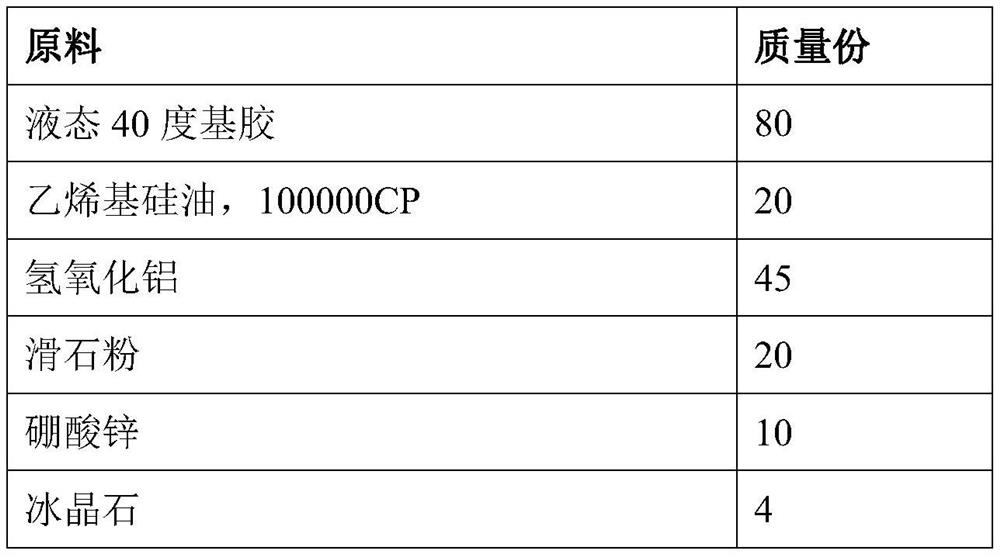

[0031] In this example, a kind of addition-type flame-retardant silicone rubber is prepared, wherein, in terms of parts by mass, the composition of the flame-retardant base rubber is shown in Table 1:

[0032] Table 1 Raw material composition of flame retardant base rubber

[0033]

[0034]

[0035] The composition of component A glue is: 100 parts of flame retardant base glue, 0.75 parts of catalyst;

[0036] The composition of component B glue is: 100 parts of flame retardant base rubber, 6 parts of hydrogen-containing silicone oil, and 0.35 parts of inhibitor.

Embodiment 2

[0038] In this example, a kind of addition-type flame-retardant silicone rubber is prepared, wherein, in terms of parts by mass, the composition of the flame-retardant base rubber is shown in Table 2:

[0039] Table 2 Raw material composition of flame retardant base rubber

[0040] raw material parts by mass Liquid 40 degree base glue 80 Vinyl silicone oil, 100000CP 20 Aluminum hydroxide 45 talcum powder 20 Zinc borate 10 cryolite 4 Sodium silicate 6

[0041] The composition of component A glue is: 100 parts of flame retardant base glue, 0.92 parts of catalyst;

[0042] The composition of component B glue is: 100 parts of flame retardant base rubber, 6 parts of hydrogen-containing silicone oil, and 0.45 parts of inhibitor.

Embodiment 3

[0044] In this example, an addition-type flame-retardant silicone rubber is prepared, wherein, in parts by mass, the composition of the flame-retardant base rubber is shown in Table 3:

[0045] Table 3 Raw material composition of flame retardant base rubber

[0046] raw material parts by mass Liquid 40 degree base glue 80 Vinyl silicone oil, 100000CP 20 Aluminum hydroxide 45 talcum powder 20 Zinc borate 10 cryolite 4 Sodium silicate 8

[0047] The composition of component A glue is: 100 parts of flame retardant base glue, 0.92 parts of catalyst;

[0048] The composition of component B glue is: 100 parts of flame retardant base rubber, 6 parts of hydrogen-containing silicone oil, and 0.45 parts of inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com