A gas lift intelligent booster plunger

A booster column and intelligent technology, applied in drilling pipes, casings, wellbore/well components, etc., can solve the problems of insufficient gas pressure, gas lift fluid failure, plunger lift fluid leakage, etc., to reduce leakage, The effect of improving the sealing performance of the plunger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the accompanying drawings and examples, but the present invention is not limited to the following embodiments.

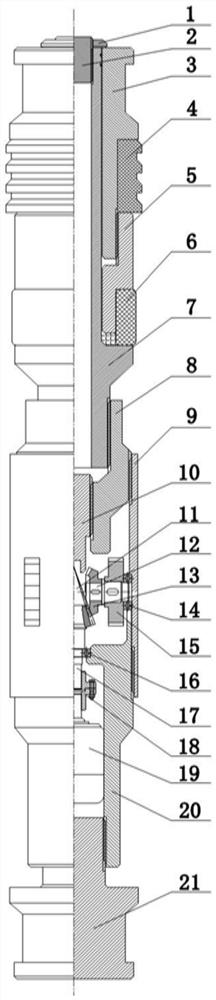

[0015] exist figure 1 Among them, a gas lift intelligent booster plunger in this embodiment has a booster motion subsection connected to the lower end of the plunger subsection, and the booster motion subsection is used to provide the crawling force in the upward process of the plunger subsection, and the plunger subsection is threaded The cone head 1, the stud 2, the upper stopper 3, the rubber scraper 4, the connecting cylinder 5, the rubber expansion cylinder 6, and the push-pull cylinder 7 are connected and constituted. The connecting cylinder 5, the upper stopper 3, a sealing packing is added between the push-pull cylinder 7 and the connecting cylinder 5, the rubber scraper 4 is installed between the upper stopper 3 and the connecting cylinder 5, and the upper stopper 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com