Modeling structure and casting method for manufacturing large floating type ingot mold

A steel ingot mould, a large-scale technology, is applied to the modeling structure and casting field of making large-scale floating steel ingot moulds, which can solve the problems of low production efficiency, unable to meet delivery requirements, high production costs, and long mold production cycles, etc., and achieve savings The production cycle, the reduction of porosity defects, and the effect of reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

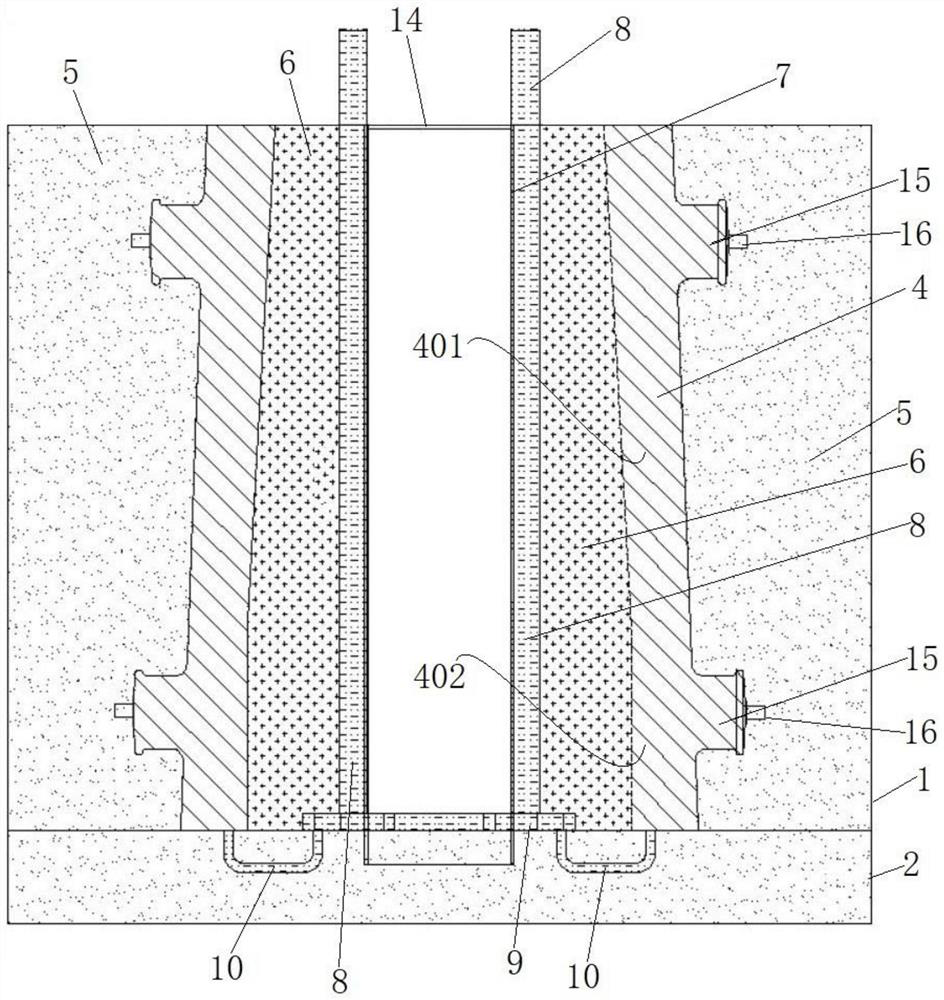

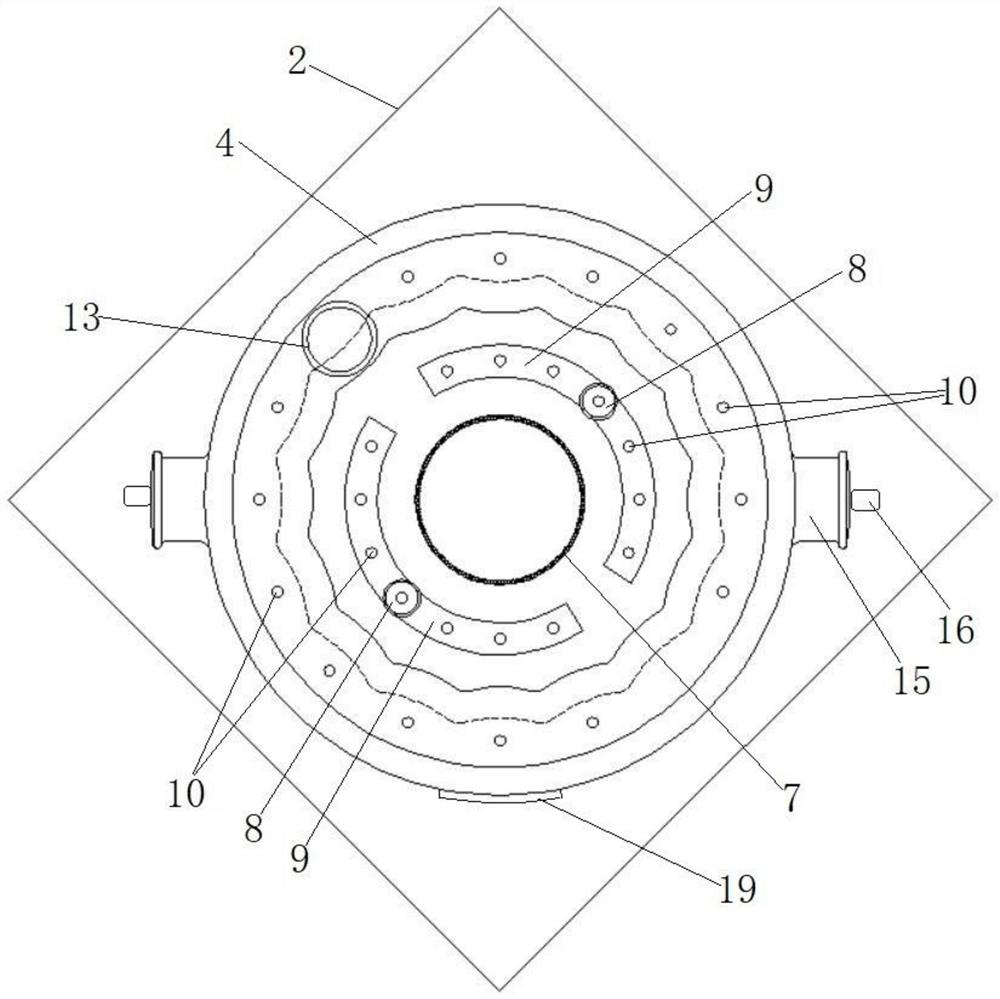

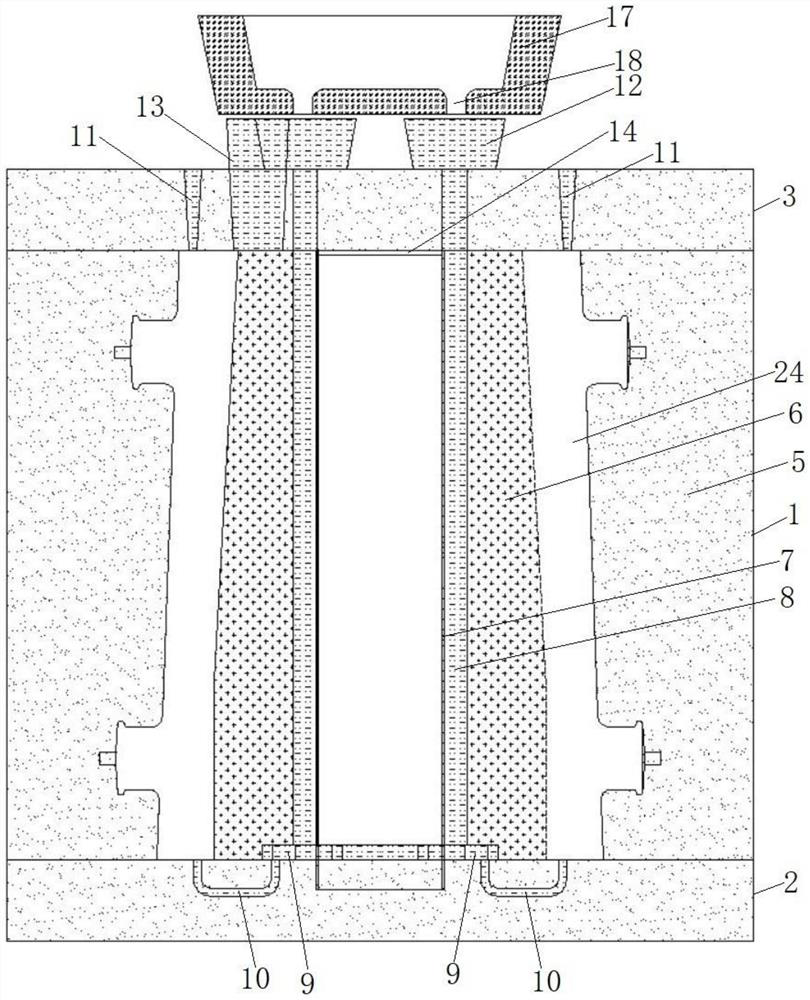

[0047] Such as Figure 1 ~ Figure 3 As shown, a modeling structure for making a large-scale floating steel ingot mould, including a bottom box 2, a middle box 1 and a cover box 3 stacked in sequence, the middle box 1 is provided with a solid foam model 4, and the solid foam model 4 Sand molds 5 are filled between the foam model 4 and the middle box 1, and the outer periphery of the solid foam model 4 is provided with several pairs of trunnion models 15, and the trunnion models 15 are provided with positioning core heads 16, and the positioning One end of the core head 16 is inserted in the sand mold 5, and the outer wall of the solid foam model 4 is also provided with a casting model, and the casting model is provided with a boss movable block 19; the inner peripheral part of the solid foam model 4 A sand core 6 is provided, and a core barrel 7 is provided in the middle of the sand core 6. A pair of sprues 8 are symmetrically arranged in the sand core 6 near the core barrel 7,...

Embodiment 2

[0067] This embodiment provides the casting method of the steel ingot mold in the first embodiment.

[0068] combine Figure 1 to Figure 8 Shown, a kind of casting method that is used to make large floating type steel ingot mould, comprises the steps:

[0069] (1) Foam pattern production: add 0.6% scale on the basis of the part drawing, add 20mm machining allowance, make a three-dimensional map of the foam model, and divide it into upper and lower parts according to the structural characteristics, that is, the floating straight part 402 and the floating part Divide the upper and lower parts into 8 equal parts in the circumferential direction; the 8 equal parts of the floating straight part are cut and formed by digital milling with a 1:1 size, and assembled after cutting to complete the floating straight part Model; the outer wall of the 8 equal parts of the module in the floating inclined section is cut and formed by digital milling at a 1:1 size, and the inner wall is reser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com