Wave-soldering spot defect detection method and system

A defect detection and solder joint detection technology, which is applied in image data processing, complex mathematical operations, instruments, etc., can solve problems such as unsatisfactory detection accuracy, and achieve the effect of facilitating effective extraction, improving yield rate, and improving accuracy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

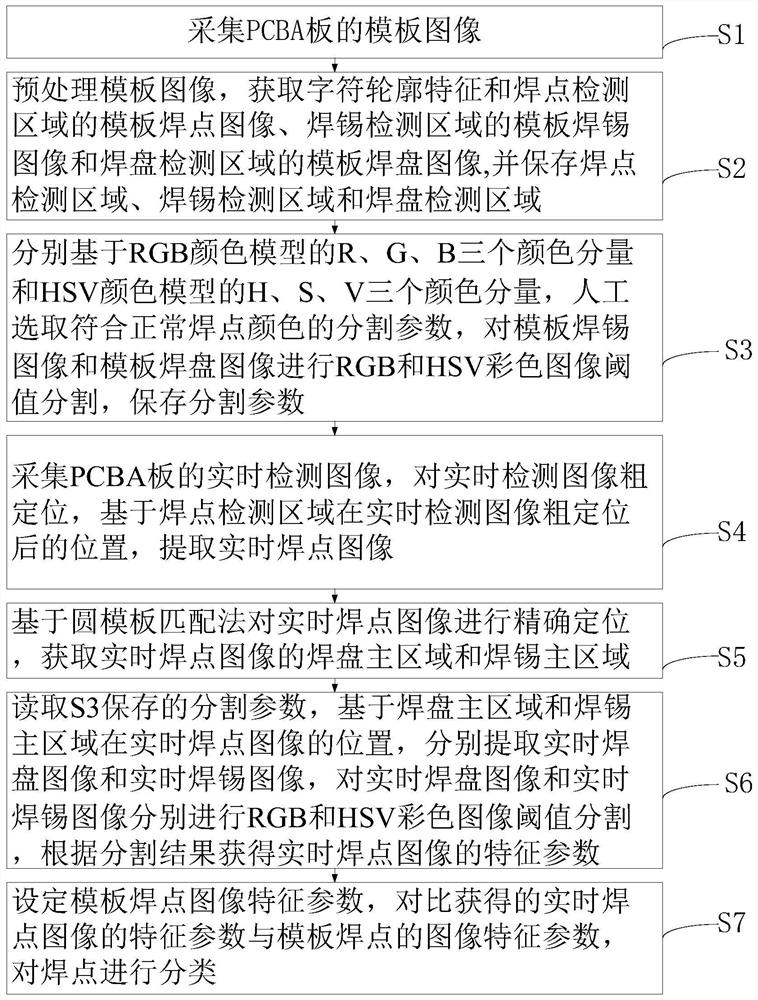

[0092] Such as figure 1 , the application proposes a wave soldering spot detection method, comprising the following steps:

[0093] S1. Collect the template image of the PCBA board;

[0094] S2. Preprocess the template image, obtain the character outline feature and the template solder joint image of the solder joint detection area, the template solder image of the solder detection area and the template pad image of the solder pad detection area, and save the solder joint detection area and the solder detection area and pad detection area;

[0095] S3. Based on the three color components of R, G, and B of the RGB color model and the three color components of H, S, and V of the HSV color model, manually select the segmentation parameters that conform to the normal solder joint color, and compare the stencil solder image and the stencil solder Perform RGB and HSV color image threshold segmentation on the disk image, and save the segmentation parameters;

[0096] S4. Collect t...

Embodiment 2

[0156] see Figure 7 , the application also proposes a wave solder joint detection system, the system is used to implement the wave solder joint detection method described in embodiment 1, the wave solder joint detection system includes:

[0157] Image acquisition module, for collecting the template image of PCBA board;

[0158] The preprocessing module is used to preprocess the template image, obtain the template solder joint image of the character outline feature and the solder joint detection area, the template solder image of the solder detection area and the template pad image of the solder pad detection area, and save the solder joint detection area , solder detection area and pad detection area;

[0159] The first threshold segmentation module is based on the three color components of R, G, and B of the RGB color model and the three color components of H, S, and V of the HSV color model. RGB and HSV color image threshold segmentation for image and stencil pad image, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com