Electronic apparatus and method for optimizing the use of motor-driven equipment in a control loop system

A control loop and equipment technology, applied in the field of optimizing the state of the control loop unit, can solve the problems such as the inability to effectively optimize the state of the control loop unit, and achieve the effects of improving reliability, reducing power consumption, and precise process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

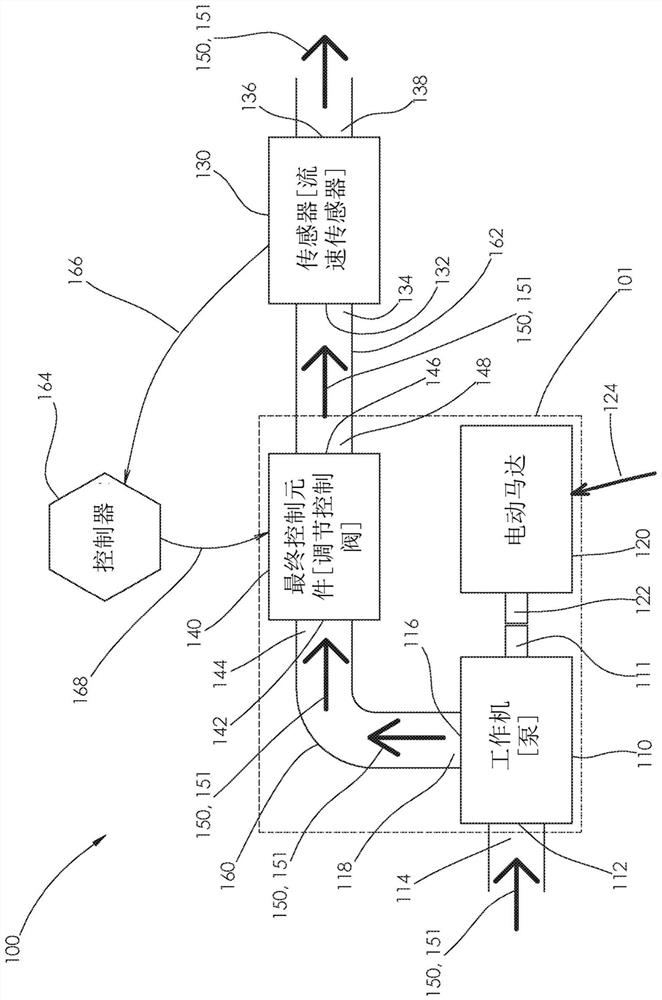

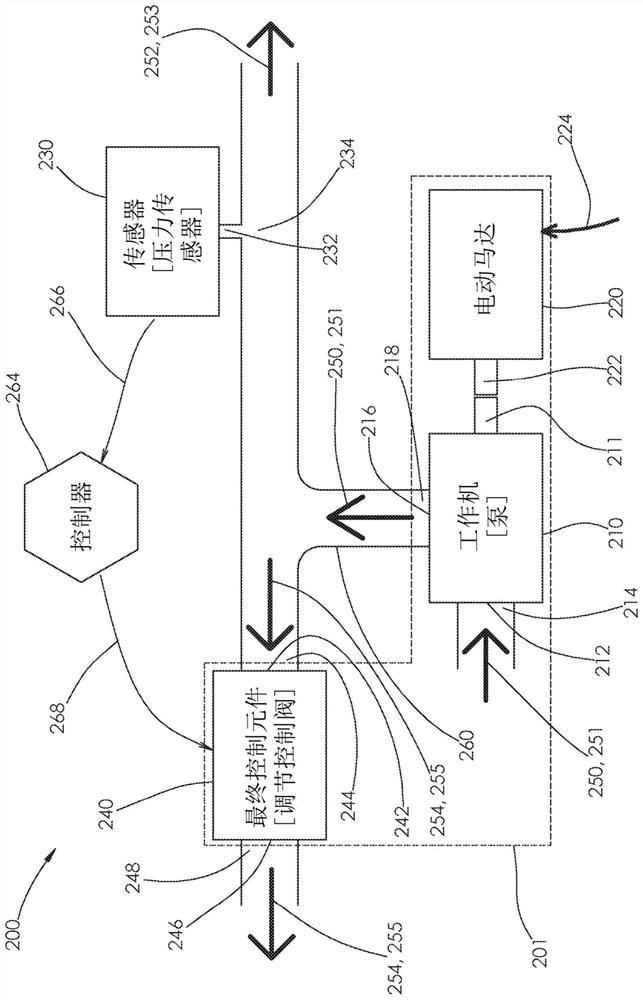

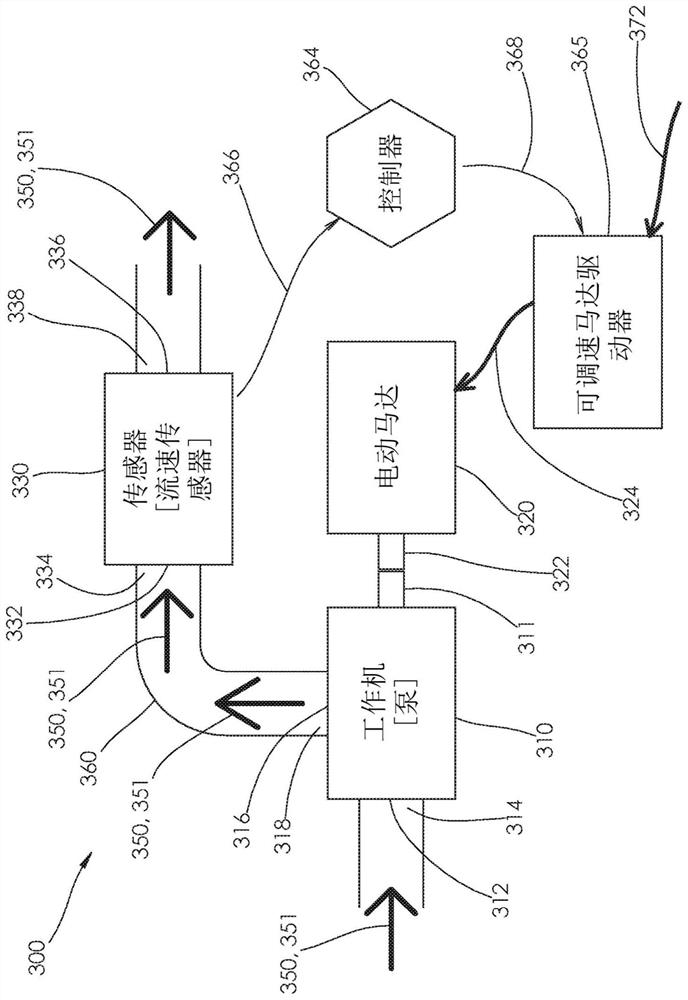

[0033] Figures 1-3 illustrate example embodiments of prior art process control loops, and it will be appreciated that an understanding of these process control loops is important to a proper understanding and appreciation of the present disclosure.

[0034] Figure 1 shows a first example implementation of a prior art control loop system (100), shown in a throttling control configuration. The control loop system (100) includes: a working machine (110), which in this embodiment includes a pump (such as a rotodynamic pump); an electric motor (120); a final control element (140) (such as a modulating control valve); a sensor (130), such as a flow rate sensor; and a process controller (164). The train (101) is defined as the three main machines in the control loop system (100), namely the pump (110), the motor (120) and the modulating control valve (140). The control loop system (100) further includes: tubing (160) connecting the pump outlet port (116) to the control valve inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com