Alpine grassland mining area rock slope regreening matrix and preparation method thereof

A technology for rock slope and mining area, which is applied to the field of re-greening of rock slope in alpine grassland mining area and its preparation field, can solve the problems of increasing slope greening cost, loss of elements, environmental damage, etc., and achieves high practical value and application. Prospect, easy operation, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

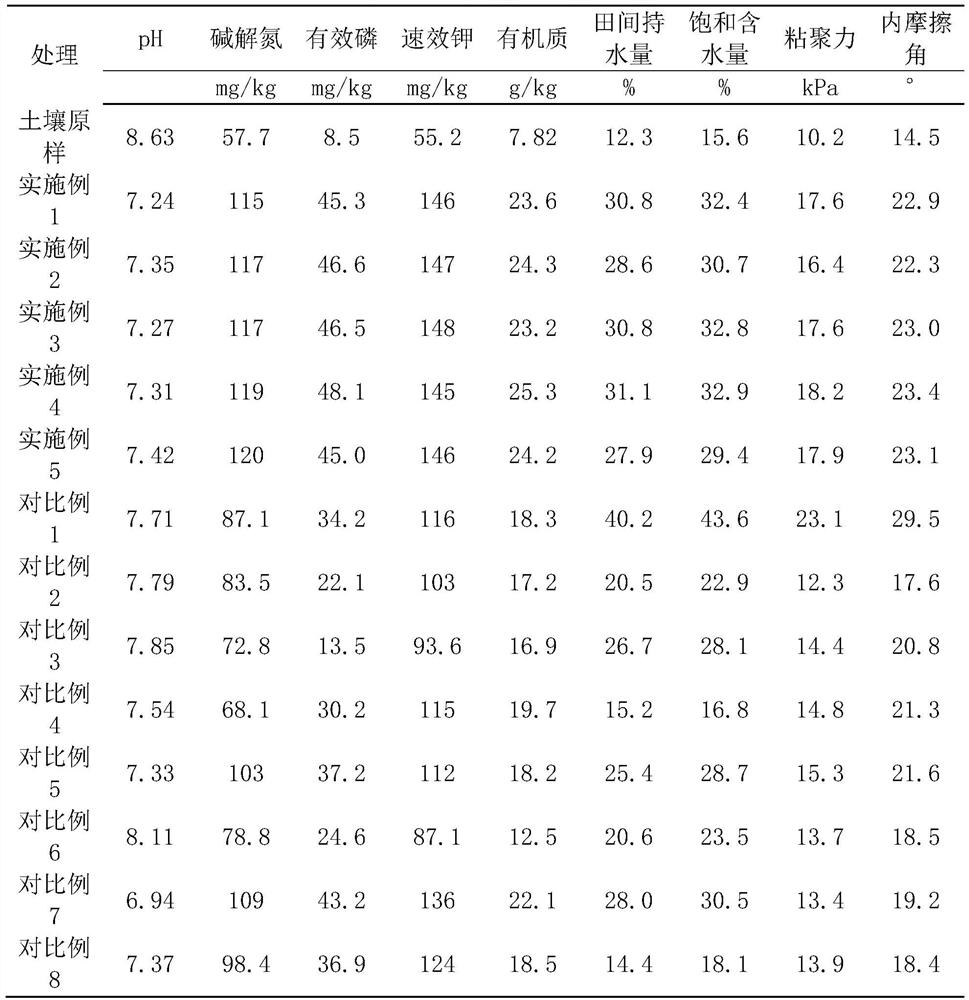

Examples

Embodiment 1

[0043] The regreen matrix of the rocky slope in the alpine grassland mining area is prepared from the following components by mass: 100 parts of mine waste land soil, 30 parts of decomposed organic waste (decomposed activated sludge), 10 parts of straw, 20 parts of slag, pulverized coal 20 parts of ash, 3 parts of binder, 2 parts of water-retaining agent (sodium polyacrylate water-absorbing resin), 3 parts of compound microbial fertilizer, 2 parts of pH regulator (superphosphate and acetic acid).

[0044] Mix the soil from mining wasteland, decomposed organic waste, straw, slag, and fly ash into a high-speed pulverizer to pulverize into particles. After sieving, the particle size is 0.10-0.15mm. Stir for 30 min at a rotation speed of 1000 r / min, and then stand for 2 h after stirring to form a stirred product. Then add water-retaining agent, binder, compound microbial fertilizer and pH regulator, stir and mix evenly to obtain rock slope regreening matrix.

Embodiment 2

[0046] The regreen matrix of the rocky slope in the alpine grassland mining area is prepared from the following components by mass: 100 parts of mine waste land soil, 30 parts of decomposed organic waste (decomposed cow and sheep manure), 5 parts of straw, 25 parts of slag, pulverized coal 15 parts of ash, 2 parts of binder, 1 part of water-retaining agent (sodium polyacrylate water-absorbing resin), 2 parts of compound microbial fertilizer, 2 parts of pH regulator (slaked lime and plant ash).

[0047] Mix the soil from mining wasteland, decomposed organic waste, straw, slag, and fly ash into a high-speed pulverizer to pulverize into particles. After sieving, the particle size is 0.10-0.15mm. Stir for 30 min at a rotation speed of 1000 r / min, and then stand for 2 h after stirring to form a stirred product. Then add water-retaining agent, binder, compound microbial fertilizer and pH regulator, stir and mix evenly to obtain rock slope regreening matrix.

Embodiment 3

[0049] The regreen matrix of the rocky slope in the alpine grassland mining area is prepared from the following components by mass: 100 parts of mine waste land soil, decomposed organic waste (the ratio of decomposed activated sludge to decomposed cow and sheep manure is 1:1) 30 parts, 8 parts of straw, 23 parts of slag, 18 parts of fly ash, 3 parts of binder, 2 parts of water-retaining agent (sodium polyacrylate water-absorbing resin), 3 parts of compound microbial fertilizer, pH regulator (superphosphate and acetic acid) 2 parts.

[0050] Mix the soil from mining wasteland, decomposed organic waste, straw, slag, and fly ash into a high-speed pulverizer to pulverize into particles. After sieving, the particle size is 0.10-0.15mm. Stir for 30 min at a rotation speed of 1000 r / min, and then stand for 2 h after stirring to form a stirred product. Then add water-retaining agent, binder, compound microbial fertilizer and pH regulator, stir and mix evenly to obtain rock slope regr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com