Efficient oil-water separation waste liquid treatment method

A technology of oil-water separation and treatment method, which is applied in the direction of semi-permeable membrane separation, chemical instruments and methods, and immiscible liquid separation. The effect of storage cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

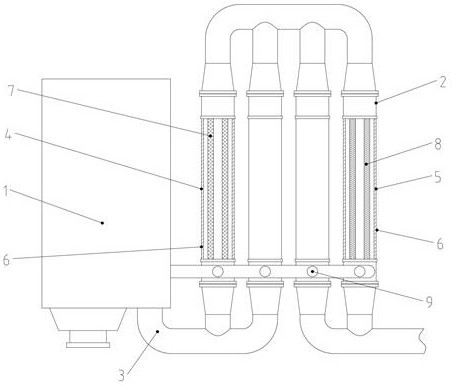

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0017] A treatment method for high-efficiency oil-water separation waste liquid. After the waste liquid is produced in the production process, it is diverted and transported to a collection container through a pipeline. In this state, the solid particles sink to the bottom, the oily liquid floats up to form the top layer, and the rest of the middle part is an aqueous solution. The oily liquid on the top layer is separately diverted and discharged and concentrated, and the middle aqueous solution is diverted to the circulation purification device. The proportion of water content is ≥85%, the mass proportion of solid particles is ≤5%, and the mass proportion of oily liquid is ≤10%.

[0018] The circulation purificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com