Shell manufacturing mold demolding device for mobile power supply production

A mobile power supply and mold manufacturing technology, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of fixed demoulding tools, inconvenient replacement, and difficulty in adaptively adjusting the size of demoulding tools, so as to reduce stress concentration , Guarantee smoothness, improve operation convenience and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

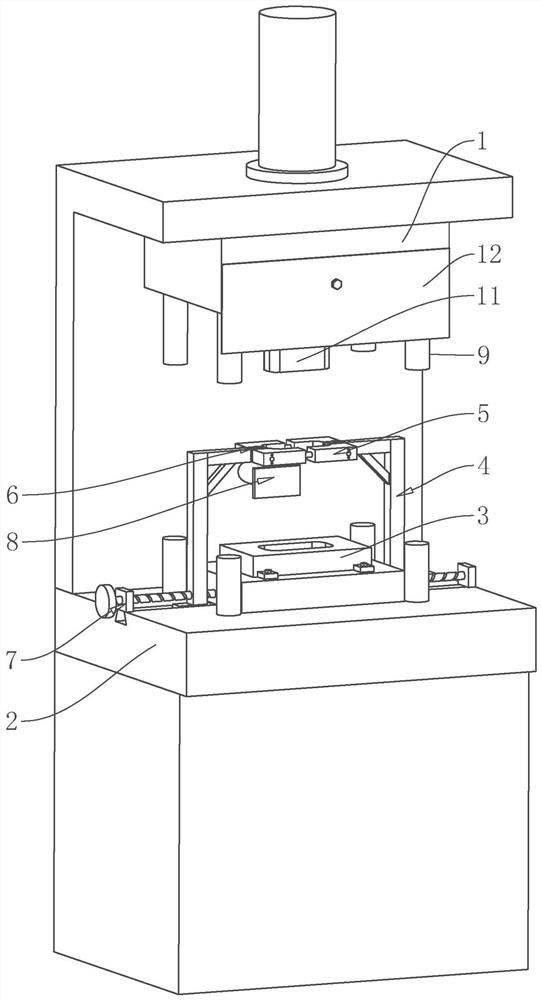

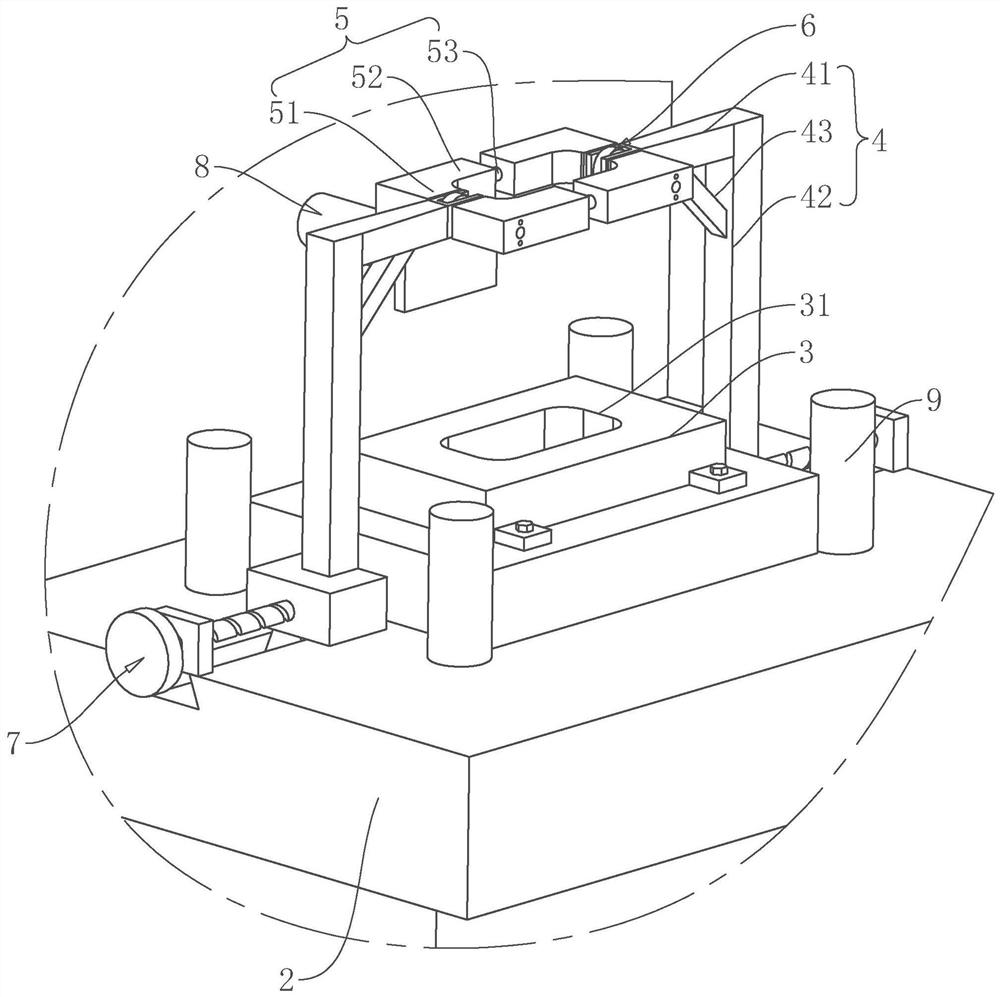

[0041] The following is attached Figure 1-5 The application is described in further detail.

[0042] The embodiment of the present application discloses a demoulding device for manufacturing a mold for a mobile power supply. refer to figure 1 , The mold demoulding device includes stamping equipment 1, a mold 11 is arranged under the stamping equipment 1, a frame 2 is arranged under the mold 11, and the frame 2 and the mold 11 are arranged at intervals. A stuffing box 3 is arranged above the frame 2, and the stuffing box 3 is connected with the frame 2 by bolts, and the stuffing box 3 is provided with a discharge trough 31 . Two supporting frames 4 are arranged above the frame 2, and the two supporting frames 4 are arranged symmetrically, and the supporting frames 4 are slidingly connected with the frame 2; a demoulding adjustment frame 5 is arranged between the two supporting frames 4.

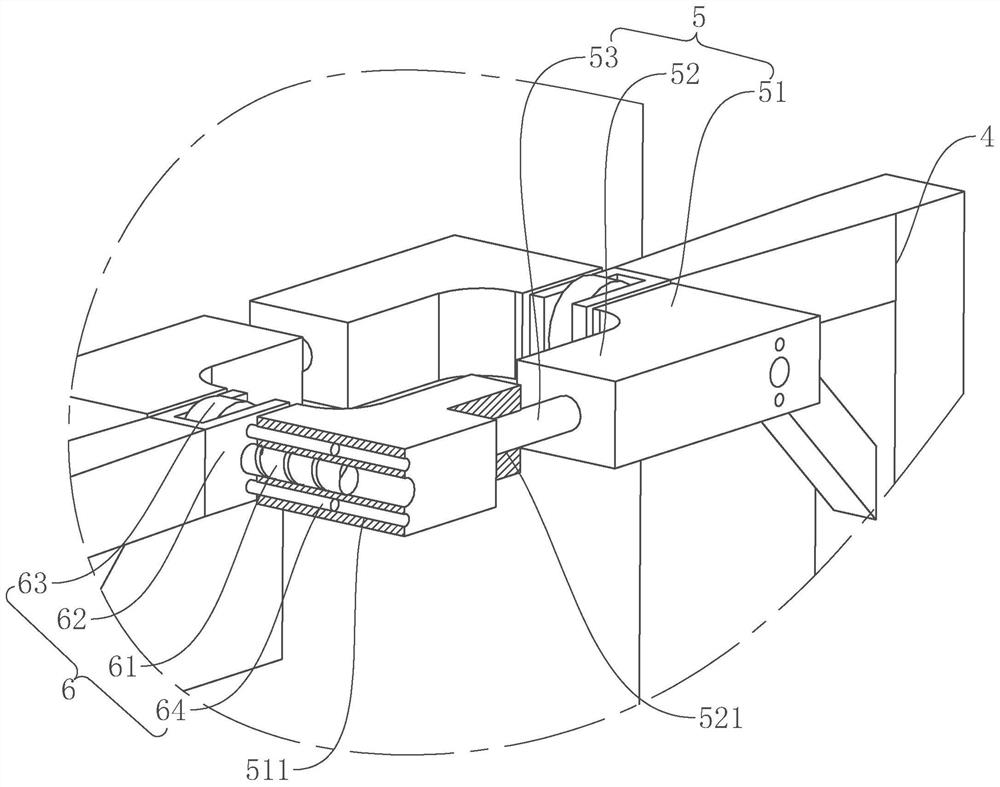

[0043] refer to figure 2 and image 3 , The demoulding adjustment frame 5 includes tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com