Composite brazing filler metal friction extrusion preparation device and preparation method

A composite brazing material and preparation device technology, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of easy moisture absorption, high cost, and loss of activity of brazing flux, and achieve excellent moisture absorption resistance and processing efficiency High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

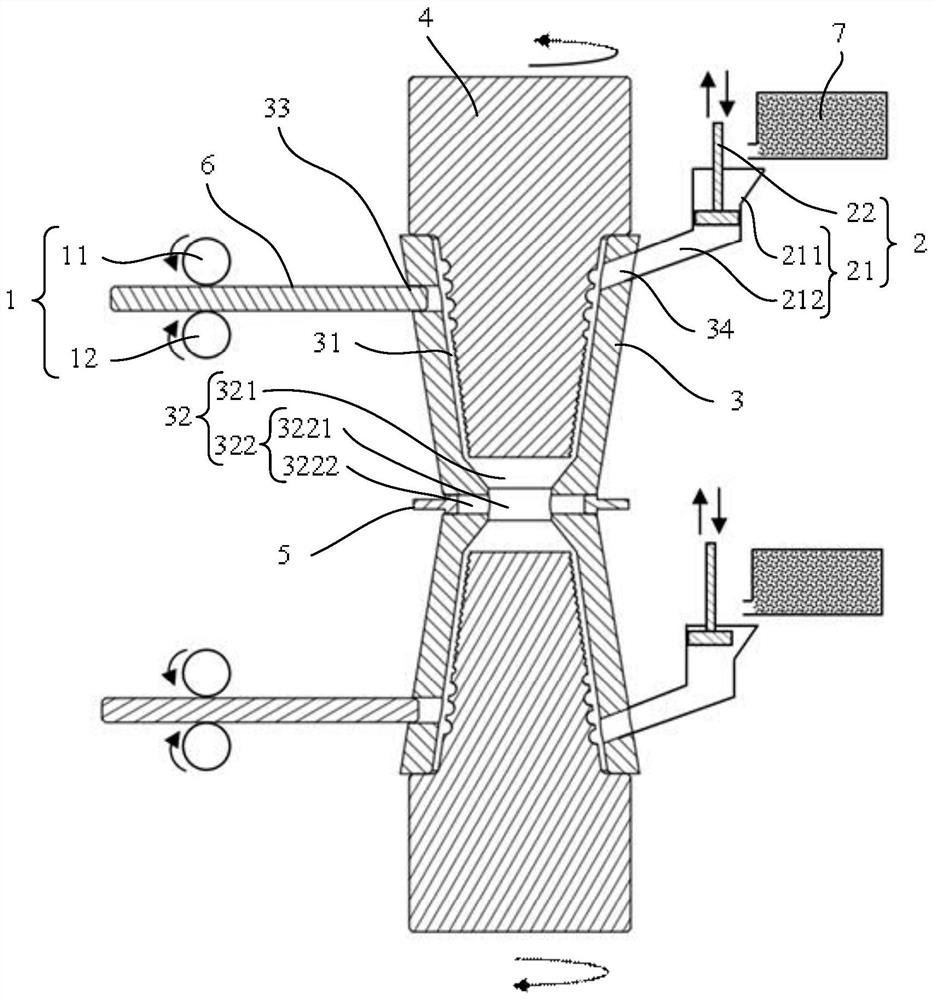

[0054] see figure 1 As shown, the embodiment of the present application provides a composite solder friction extrusion preparation device, including: a first feeding mechanism 1, a second feeding mechanism 2, a molding die 3 and an auxiliary molding member 4; wherein, the molding die 3 An installation cavity is formed, the auxiliary molding member 4 is arranged in the installation cavity, and a first extrusion molding cavity 31 is formed between the side wall of the auxiliary molding member 4 and the side wall of the installation cavity of the molding die 3;

[0055] The first feeding mechanism 1 is used to transport the brazing material rod 6 to the first extruding chamber 31 through the brazing material inlet 33, and the second feeding mechanism 2 is used to feed the brazing powder 7 through the brazing flux inlet 34. Transported into the first extrusion molding cavity 31, and the auxiliary molding member 4 can be driven by external force to rotate relative to the molding di...

Embodiment 2

[0094] Embodiment 2 of the present application also provides a kind of composite solder friction extrusion preparation method, utilizes the composite solder friction extrusion preparation device described in above-mentioned embodiment 1, thus, has all the components of the composite solder friction extrusion preparation device Beneficial technical effects, the same technical features and beneficial effects will not be repeated.

[0095] In this embodiment, preferably, as figure 1 As shown, the preparation method of composite solder friction extrusion comprises the steps:

[0096] Step 201: The 4047 aluminum rod with a diameter of 9.5±0.5mm, that is, the brazing material rod 6 is drawn into a full circle through a sizing die, and then enters a mechanical scraping die to remove 0.04mm of oxide skin, and is pressed by the first feeding mechanism 1. The rollers, that is, the first pressing roller 11 and the second pressing roller 12 are continuously sent into the brazing material...

Embodiment 3

[0107] The preparation method of composite solder friction extrusion involved in this embodiment is the same as the method steps disclosed in Embodiment 2, the only difference is:

[0108] Step 301 is the same as step 201, and will not be described in detail here;

[0109] Step 302 is the same as step 202, and will not be described in detail here;

[0110] Step 303 is the same as step 203, the difference is that what is obtained is a semi-finished filamentary composite solder with a diameter of 2.3 mm;

[0111] Step 304: Draw the filamentary composite solder wire with a diameter of 2.3 mm to 2.0 mm, straighten it with a straightener, and use an automatic cutting machine to form a straight composite solder wire with a length of 500 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com