Aluminate cement-based powder accelerator, and preparation method and application thereof

A kind of aluminate cement and cement-based technology, which is applied in the field of building material admixtures, can solve the problems that the quick-setting effect cannot meet the demand, the loss of 28d compressive strength is large, and the cost is high, so as to achieve good quick-setting effect, production equipment and personnel The effect of low requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

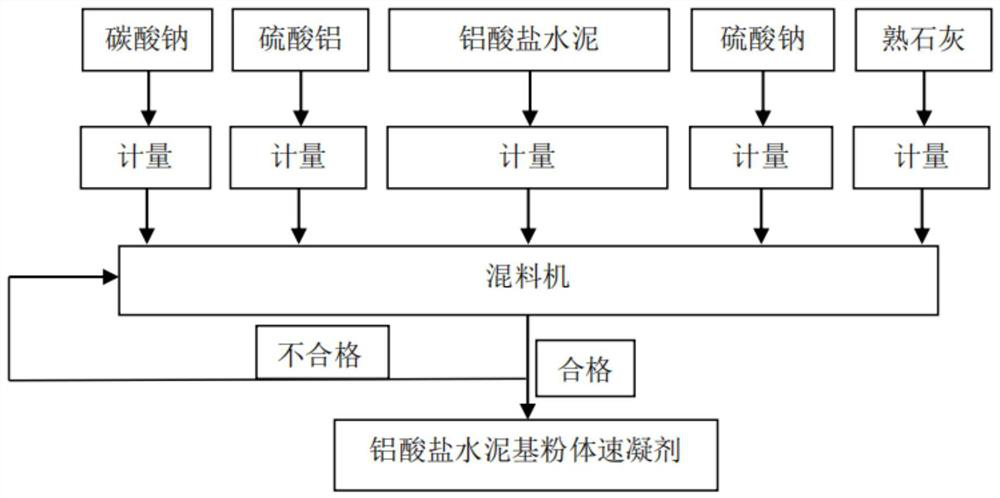

[0030] Preparation method of an aluminate cement powder fungier of the present invention, such as figure 1 As shown, the following steps include the following steps: Aluminate cement, sodium carbonate, aluminum sulfate, sulfate, cooked lime mixed in the mixture in the mixing machine, according to the standard "spray concrete" in the building materials industry (JC " 477-2005) Test was performed, and the aluminate cement-based powder veneer was obtained.

[0031] The aluminate cement powder racturing agent provided by the present invention has: (1) good speed, the initial coagulation is adjustable between 3 to 7 minutes, and the final reaches is adjustable between 5 to 12min; (2) 1D compressive strength is high, adjustable between 7 to 11 MPa; (3) 28D compressive strength loss is small; (4) good features of different cement applicability.

[0032] The present invention has low requirements for production equipment and personnel, short production cycle, low production cost, and the ...

Embodiment 1

[0040] The aluminate cement powder percursion agent of the present embodiment is: the preparation method is: 5000 g of aluminate cement, 1500g of sodium carbonate, 1000 g of sulfate, 1000 g of sulfate, and a mature lime 500g, add the grinding mixer, mixed. 350m specific surface area 2 / kg, in accordance with the standard "spray concrete speed coagulant" (JC 477-2005) by the building materials industry, the aluminate cement-based powder perimecase is obtained.

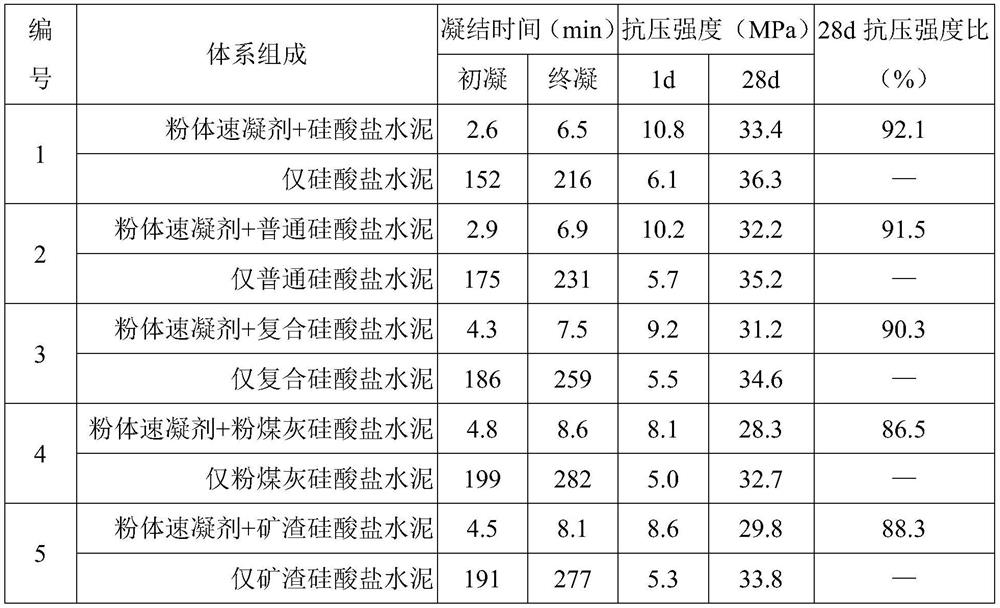

[0041]Different cement, such as silicate cement, ordinary silicate cement, composite silicate cement, fly ash silicate cement, mineralolate silicate cement, in accordance with the standard of building materials industry "The provisions of the condensation time are tested, in which 400 g, aluminate cement powder speed coagulant is 24 g, water 160g, and the test results are shown in Table 1.

[0042] Different cement, such as silicate cement, ordinary silicate cement, composite silicate cement, fly ash silicate cement, miner...

Embodiment 2

[0051] The aluminate cement-based powder percorator of the present embodiment is different from the difference in the addition of each of the raw materials. Specifically, the aluminate cement 4000g, sodium carbonate is 2000g, aluminum sulfate, 1500 g sodium sulfate, and sodium sulfate. The preparation of 1000g, preparation method and performance test method are the same as in Example 1, and will not be described again.

[0052] The condensation time and the compressive strength test result of the aluminate cement powder velocgertant and different cements are shown in Table 3.

[0053] Table 3 Different cement coagulation time and compressive strength test results

[0054]

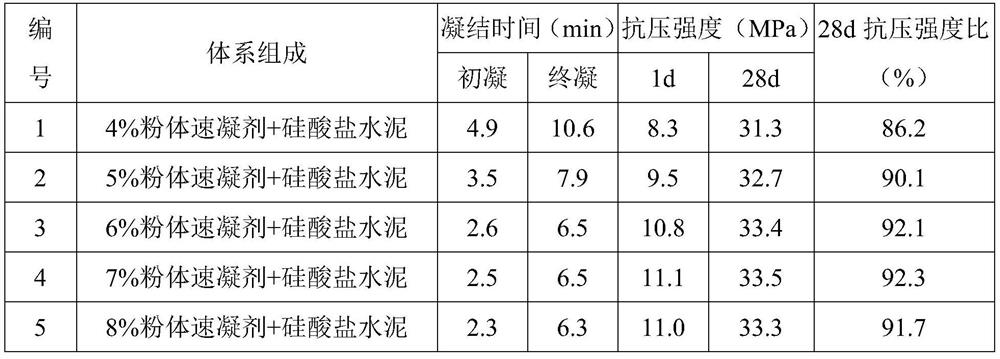

[0055] As can be seen from Table 3 and Table 2, when the composition of the powdered powder condensant is constructed in the specified proportional range, the aluminate cement-based powder of the present invention is still having a variety of silicate cement Good matching. Similarly, when the amount of silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com