Synthesis method of phenylhydrazone derivative of aloe pines

A synthetic method, the technology of aloe vera pine, applied in the field of biomedicine, achieves the effect of short reaction time, simple operation steps and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

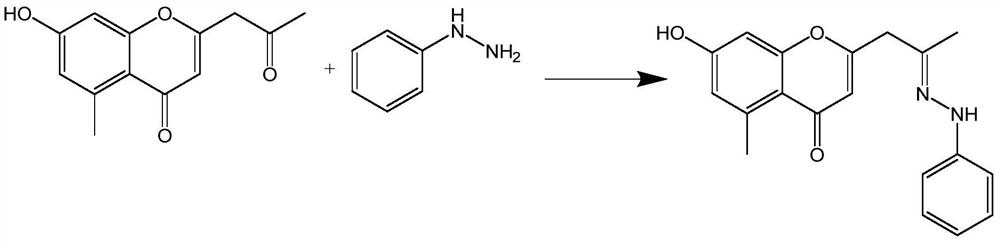

Image

Examples

Embodiment 1

[0025] The synthetic method of the phenylhydrazone derivative of embodiment 1 aloe vera pine

[0026] (1) Compound 1-1 (10mmoL, 2.322g) was dissolved in 20mL butanol, then phenylhydrazine (10mmoL, 1.081g) and auxiliary agent (10mmoL, 0.845g) were added, and the reaction was stirred at room temperature 25°C for 3h, Concentrate under reduced pressure to obtain a concentrate; the auxiliary agent is p-toluenesulfonic acid and sodium acetate (molar ratio 0.3:10);

[0027] (2) The concentrate was separated and purified by column chromatography (petroleum ether: ethyl acetate = 4:1, v / v) to obtain a yellow oily product (2.163 g, yield 67%).

Embodiment 2

[0028] The synthetic method of the phenylhydrazone derivative of embodiment 2 aloe pine

[0029] (1) Dissolve compound 1-1 (10mmoL, 2.322g) in 20mL butanol, then add phenylhydrazine (12mmoL, 1.296g) and additives (12mmoL, 1.015g), and stir the reaction at room temperature 25°C for 3h, Concentrate under reduced pressure to obtain a concentrate; the auxiliary agent is p-toluenesulfonic acid and sodium acetate (molar ratio 0.3:10);

[0030] (2) The concentrate was separated and purified by column chromatography (petroleum ether: ethyl acetate = 4:1, v / v) to obtain a yellow oily product (2.226 g, yield 69%).

Embodiment 3

[0031] The synthetic method of the phenylhydrazone derivative of embodiment 3 aloe vera pine

[0032] (1) Compound 1-1 (10mmoL, 2.322g) was dissolved in 20mL butanol, then phenylhydrazine (12mmoL, 1.296g) and auxiliary agent (12mmoL, 1.036g) were added, and the reaction was stirred at room temperature 25°C for 3h, Concentrate under reduced pressure to obtain a concentrate; the auxiliary agent is p-toluenesulfonic acid and sodium acetate (molar ratio 0.5:10);

[0033] (2) The concentrate was separated and purified by column chromatography (petroleum ether: ethyl acetate = 4:1, v / v) to obtain a yellow oily product (2.160 g, yield 67%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com