Super-hydrophobic metal organic framework material as well as preparation method and application thereof

A metal-organic framework and super-hydrophobic technology, which is applied in the field of super-hydrophobic metal-organic framework materials and their preparation, can solve the problems of reducing the specific surface area and surface mass transfer rate of metal-organic framework materials, and achieves good application value and prospect, and is widely used. properties, and the effect of solving poor water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

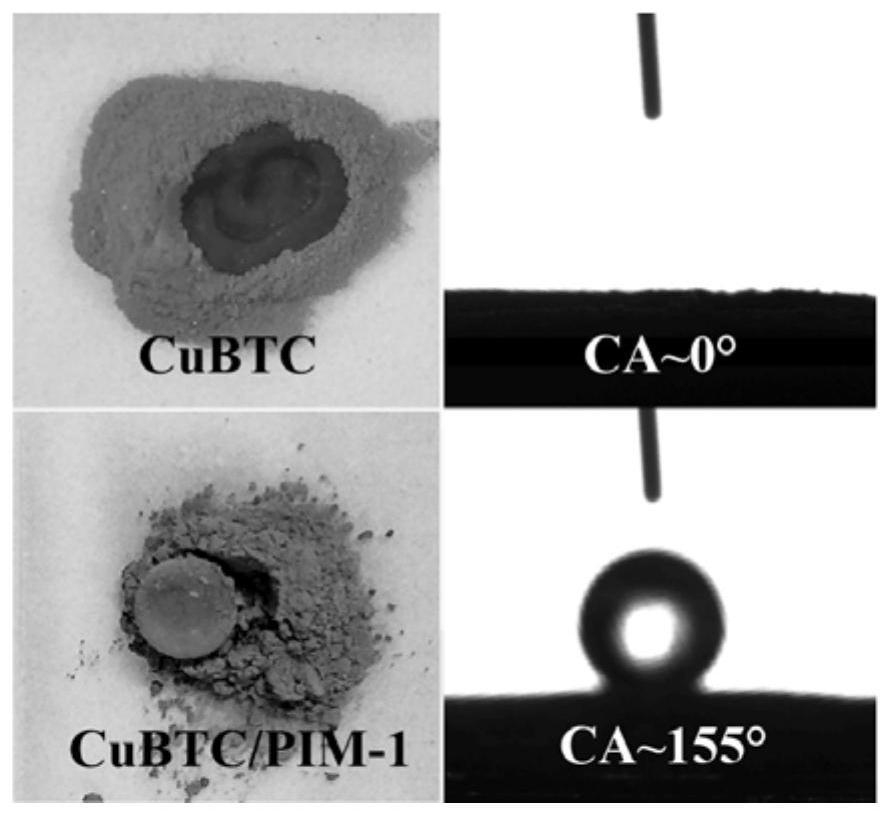

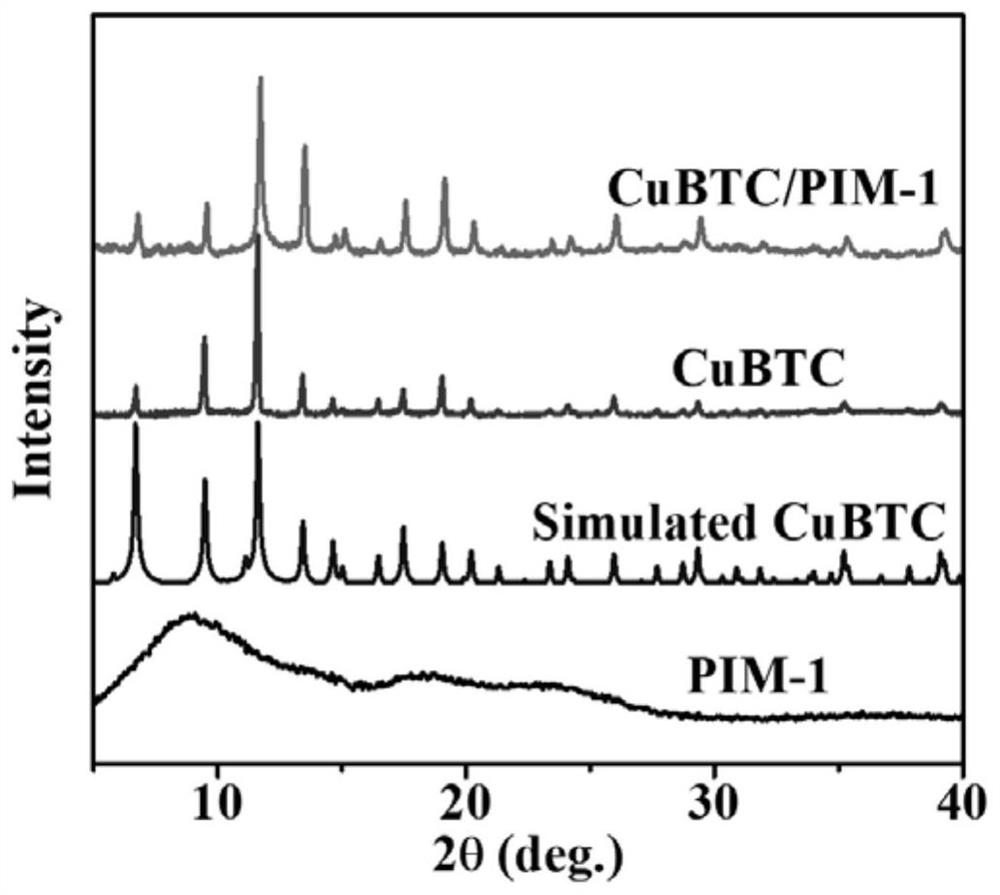

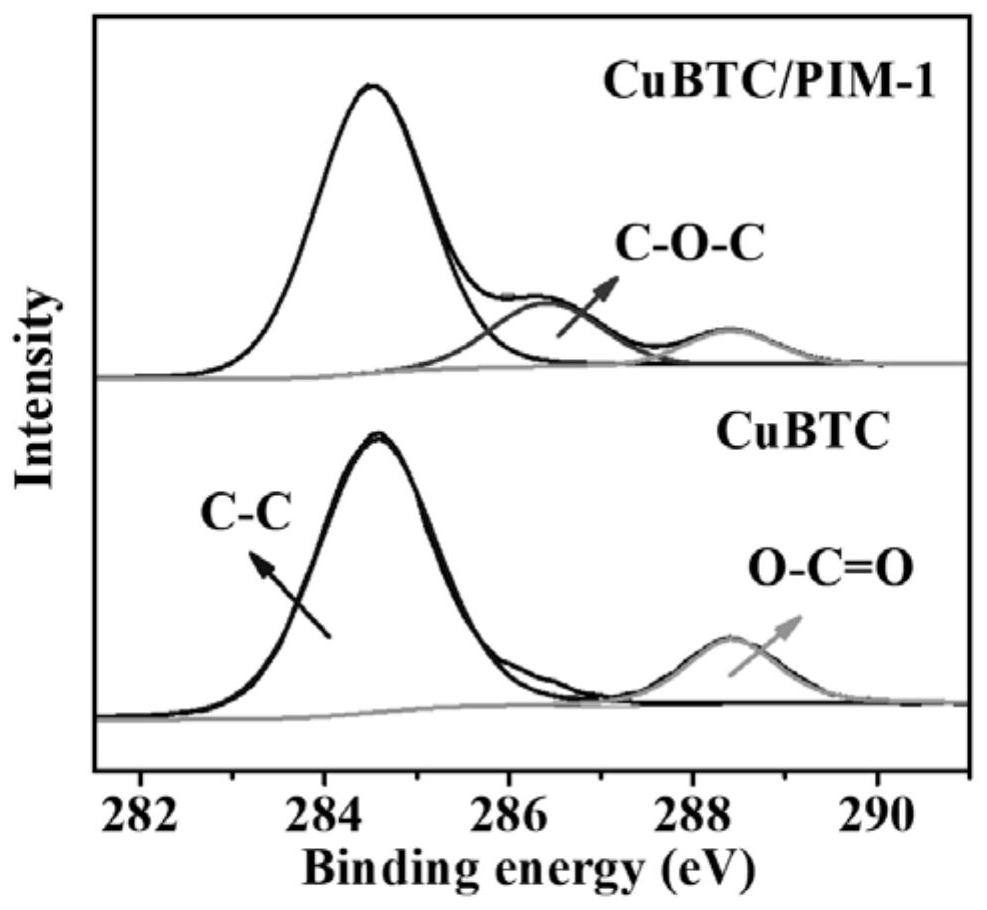

[0045] The hydrophobic microporous polymer is PIM-1, the metal-organic framework is CuBTC, and the synthesized superhydrophobic metal-organic framework is CuBTC / PIM-1.

[0046]Preparation:

[0047] (1) Synthesis of hydrophobic microporous polymer: 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'- Spiral bisindane (3.404g), tetrafluoroterephthalonitrile (2.001g) and potassium carbonate (3.414g) were added in a three-necked flask, and after nitrogen was passed through for 30min, N-methylpyrrolidone (20mL) and toluene ( 10 mL), then the above mixture was transferred to an oil bath at 160 °C and stirred for 40 min. After the reaction, the obtained viscous liquid was poured into methanol, then stirred and washed with deionized water and acetone, and finally vacuum-dried at 120° C. for 48 hours to obtain a hydrophobic microporous polymer.

[0048] (2) Synthesis of metal-organic framework CuBTC: using the hydrothermal synthesis method commonly used for metal-organic frameworks, co...

Embodiment 2

[0052] The hydrophobic microporous polymer is PIM-1, and the metal-organic framework is UiO-66-NH 2 , the synthesized superhydrophobic metal-organic framework is UiO-66-NH 2 / PIM-1.

[0053] Preparation:

[0054] (1) Synthesis of hydrophobic microporous polymer: 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'- Spiral bisindane (5.106g), tetrafluoroterephthalonitrile (3.002g) and potassium carbonate (5.121g) were added in a three-necked flask, and after nitrogen was passed through for 40min, N-methylpyrrolidone (30mL) and toluene ( 15 mL), then the above mixture was transferred to an oil bath at 150 °C and stirred for 40 min. After the reaction, the obtained viscous liquid was poured into methanol, then stirred and washed with deionized water and acetone, and finally vacuum-dried at 110° C. for 36 hours to obtain a hydrophobic microporous polymer.

[0055] (2) Metal organic framework UiO-66-NH 2 Synthesis of: Using the hydrothermal synthesis method commonly used in metal...

Embodiment 3

[0058] The hydrophobic microporous polymer is PIM-1, the metal organic framework is MIL-101, and the synthesized superhydrophobic metal organic framework is MIL-101 / PIM-1.

[0059] Preparation:

[0060] (1) Synthesis of hydrophobic microporous polymer: 5,5',6,6'-tetrahydroxy-3,3,3',3'-tetramethyl-1,1'- Spiral bisindane (6.808g), tetrafluoroterephthalonitrile (4.002g) and potassium carbonate (8.28g) were added in a three-necked flask, and after passing through nitrogen for 50min, N-N dimethylformamide (40mL) was added, followed by The above mixture was transferred to an oil bath at 170 °C and stirred for 40 min. After the reaction, the obtained viscous liquid was poured into methanol, then stirred and washed with deionized water and acetone, and finally vacuum-dried at 110° C. for 36 hours to obtain a hydrophobic microporous polymer.

[0061] (2) Synthesis of metal-organic framework MIL-101: using the hydrothermal synthesis method commonly used for metal-organic frameworks, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com