Preparation method of low-oxygen-content Zr-based bulk amorphous alloy

An amorphous alloy, low oxygen content technology, applied in the field of low oxygen content Zr-based bulk amorphous alloy preparation, can solve the problems such as the increase in the volume occupied by the crystal phase and the decrease in the amorphous forming ability of the Zr-based alloy, and the composition can be achieved. Control, improve and stabilize performance, prevent gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

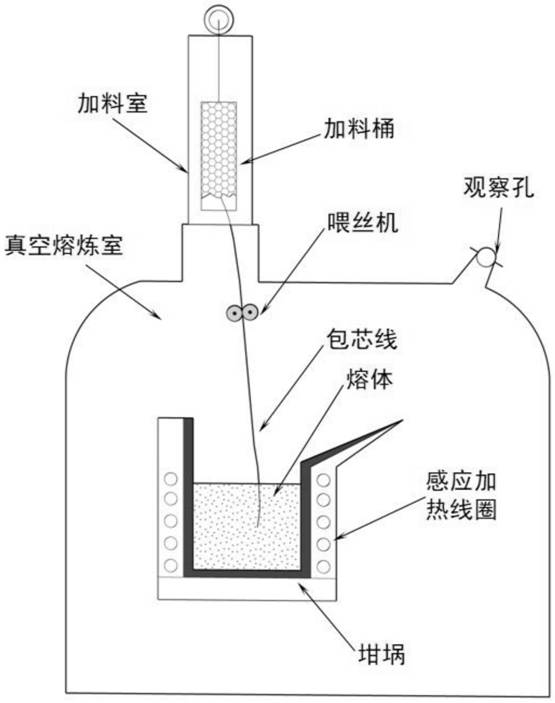

Method used

Image

Examples

Embodiment 1

[0025] 1. Ingredients

[0026] Accurately weigh Zr52.5kg, Cu17.9kg, Ni14.6kg, Al10kg, Ti5kg.

[0027] 2. Melting operation

[0028] 1) Feed the raw materials in such a way that the large pieces are close to the inner wall of the crucible, and the small pieces are close to the center of the crucible;

[0029] 2) Close the furnace cover, turn on the vacuum pump, and pump the vacuum of the melting furnace to within 5Pa;

[0030] 3) Set the power of the melting furnace to 30KW, supply electricity to heat up, and when the metal in the crucible starts to melt, increase the power to 60KW for melting;

[0031] 4) Melt until splashing occurs, reduce the power to 10KW, turn off the vacuum pump, and fill the furnace with argon to increase the vacuum pressure of the furnace to 200Pa;

[0032] 5) Put the amorphous alloy into the crucible for vacuum melting, the melting temperature is 950°C, and use Al, Ti, Ca, Y composite twisted wire, and feed the crucible twice through the sealed wire...

Embodiment 2

[0037] 1. Ingredients

[0038] Accurately weigh Zr52.5kg, Cu17.9kg, Ni14.6kg, Al10kg, Ti5kg.

[0039] 2. Melting operation

[0040] 1) Feed the raw materials in such a way that the large pieces are close to the inner wall of the crucible, and the small pieces are close to the center of the crucible;

[0041] 2) Close the furnace cover, turn on the vacuum pump, and pump the vacuum of the melting furnace to within 5Pa;

[0042] 3) Set the power of the melting furnace to 50KW, supply electricity to heat up, and when the metal in the crucible starts to melt, increase the power to 80KW for melting;

[0043] 4) Melt until splashing occurs, reduce the power to 30KW, turn off the vacuum pump, and fill the furnace with argon to increase the vacuum pressure of the furnace to 500Pa;

[0044] 5) Put the amorphous alloy into the crucible for vacuum melting, the melting temperature is 1300°C, and use Al, Ti, Ca, Y composite twisted wire, and feed the crucible twice through the sealed wir...

Embodiment 3

[0049] 1. Ingredients

[0050] Accurately weigh Zr52.5kg, Cu17.9kg, Ni14.6kg, Al10kg, Ti5kg.

[0051] 2. Melting operation

[0052] 1) Feed the raw materials in such a way that the large pieces are close to the inner wall of the crucible, and the small pieces are close to the center of the crucible;

[0053] 2) Close the furnace cover, turn on the vacuum pump, and pump the vacuum of the melting furnace to within 5Pa;

[0054] 3) Set the power of the melting furnace to 40KW, supply electricity to heat up, and when the metal in the crucible starts to melt, increase the power to 70KW for melting;

[0055] 4) Melt until splashing occurs, reduce the power to 20KW, turn off the vacuum pump, and fill the furnace with argon to increase the vacuum pressure of the furnace to 400Pa;

[0056] 5) Put the amorphous alloy into the crucible for vacuum melting, the melting temperature is 1150°C, and use Al, Ti, Ca, Y composite twisted wire, and feed the crucible twice through the sealed wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com