Rotary limiting device and using method thereof

A technology of rotation limit and rotation axis, which is applied in the direction of mechanical equipment, brake types, etc., can solve the problems of poor environmental protection and large energy consumption, and achieve the effect of not easy to loosen, reduce energy consumption, and simple structure of the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

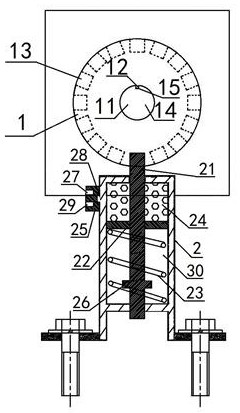

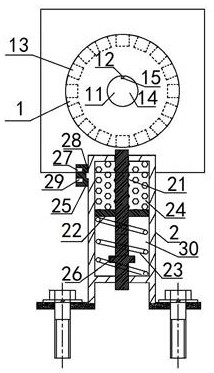

[0048] A kind of rotation limit device, the rotation limit device comprises: a rotation limit turntable 1 and a piston cylinder 2; The rotating shaft 14 is fixedly connected, the rotating limit turntable 1 is coaxially arranged with the rotating shaft 14, and a plurality of limit holes 13 are evenly opened on the outer circumference of the rotating limit turntable 1; the piston cylinder 2 is provided with A retractable piston rod 21, the piston rod 21 is arranged directly below the rotation limit turntable, the piston rod 21 passes through the top plate of the piston cylinder 2 and is inserted into the limit hole 13, and the piston rod 21 passes through it The sealing plate 22 provided on the upper part slides and cooperates with the side wall of the piston cylinder 2, and the sealing plate 22 is in sealing cooperation with the side wall of the piston cylinder 2, and the sealing plate 22 separates the piston cylinder 2 into an oil chamber 24 and a spring chamber 30, The oil ch...

Embodiment 2

[0055] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0056] The oil chamber 24 is arranged above the sealing plate 22, the spring chamber 30 is arranged below the sealing plate 22, the top of the spring 23 is press fit with the bottom of the sealing plate 22, and the bottom of the spring 23 is in contact with the sealing plate 22. The top of the plate 22 is a press fit.

Embodiment 3

[0058] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0059] The number of the positioning wedge 12 is three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com