Line impedance stabilization network structure suitable for pulse current injection

A technology of line impedance and network structure, applied in the field of electromagnetic pulse conduction effect experiments, can solve the problems of inability to guarantee electromagnetic pulse protection capability, inability to guarantee insulation breakdown, and high voltage peaks, so as to improve the electromagnetic pulse protection performance, protect the external power grid, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below:

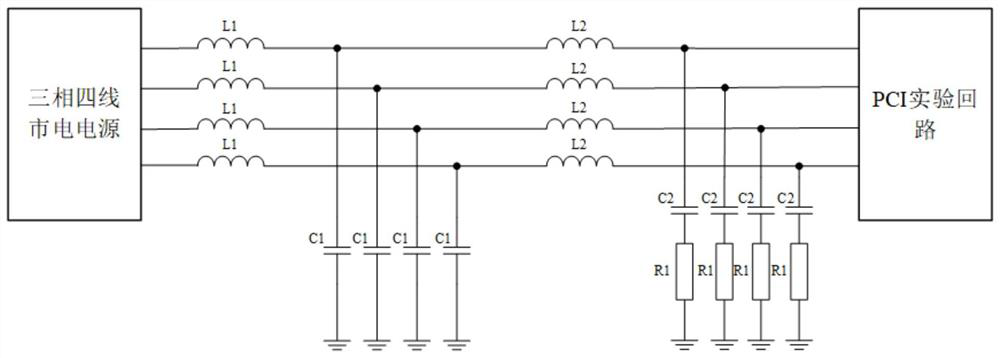

[0030] A line impedance stabilization network (LISN) structure suitable for pulse current injection, the LISN structure is designed as a three-phase four-wire structure, composed of four branches with the same circuit structure.

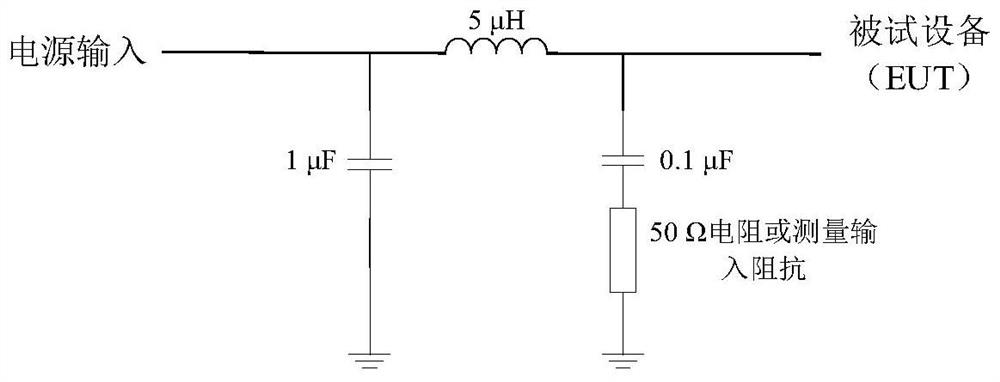

[0031] In terms of circuit structure design, on the basis of the conventional 5μH type LISN circuit structure in GJB 151B-2013, the capacitance value of the ground capacitance and the first-level inductance are increased, so the circuit structure of each branch of the LISN is an L-C-L T A type low-pass filter is connected in parallel with a capacitor-resistance branch. This structure has the impedance stability curve of the 5μH type LISN in GJB 151B-2013 and good pulse current protection performance.

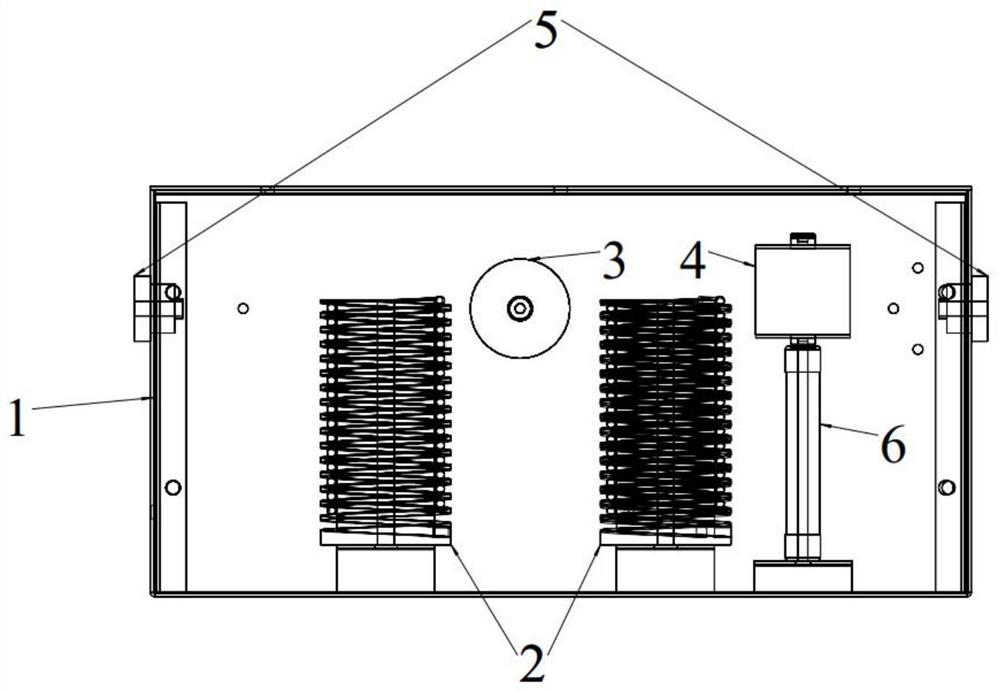

[0032]The physical structure of the LISN structure includes a stainless steel shell 1, a 5μH air core inductor with enhanced inter-turn pressure resistance 2, a 30μF polypropylene fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com