Eucommia seed oil microcapsule, eucommia seed oil whitening essence, preparation method and application

A technology of eucommia ulmoides seed oil and microcapsules, which can be used in pharmaceutical formulations, cosmetic preparations, toiletry preparations, etc. It can solve the problems of oxidative damage and oxidative rancidity of eucommia ulmoides seed oil, so as to delay oxidative rancidity and resist oxidation. And the effect of improving the whitening performance and increasing the bearing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides the preparation method of eucommia seed oil microcapsules described in the above scheme, comprising the following steps:

[0037] 1) mixing gum arabic and water to obtain the first solution;

[0038] 2) mixing chitosan and acetic acid aqueous solution to obtain a second solution;

[0039] 3) mixing Eucommia ulmoides seed oil, Tween 85 and the first solution to obtain a third solution;

[0040] 4) adding the second solution dropwise to the third solution to obtain a fourth solution; the dropping speed is to add 8 to 12 g of the second solution per minute;

[0041] 5) After adjusting the pH of the fourth solution to 4.1-4.3, let stand at 4-6° C. for 25-35 minutes to obtain a gel;

[0042] 6) Adjust the pH of the gel to 6.3-6.8 to obtain a weak acid gel, mix the weak acid gel with an aqueous solution of transglutaminase, and let it stand at 28-32° C. for 0.8-1.2 hours, solid-liquid Separation and collection of precipitates;

[0043] 7) fr...

Embodiment 1

[0062] 1. Pretreatment of wall materials: Dissolve 5g of gum arabic in 51.25g of water to obtain the first solution.

[0063] 2. Dissolve 0.625g of chitosan in 55.63g of acetic acid aqueous solution (the mass percent of glacial acetic acid in the acetic acid aqueous solution is 1%), heat and stir at 60° C. to dissolve at 500 rpm to obtain the second solution.

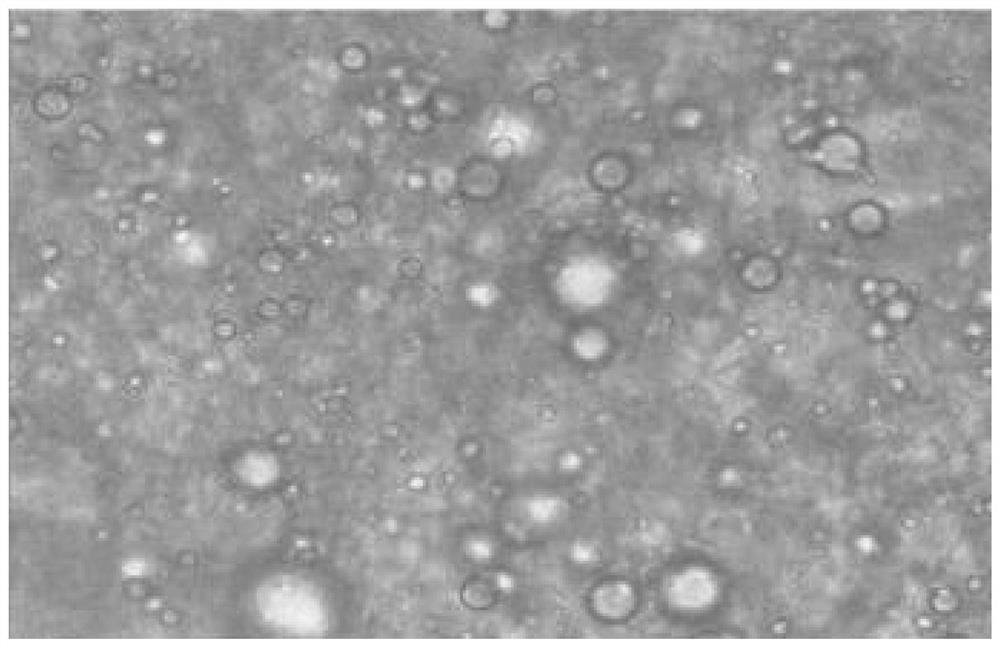

[0064] 3. Emulsification: Take 1.4g of Eucommia ulmoides seed oil (purchased from Jiangxi Hailin Perfume Co., Ltd.), 2g of Tween 85, add 50g of the first solution to it, and stir at 8000rmp for 5min to obtain the third solution;

[0065] 4. Wrapping: Add the second solution dropwise into the third solution at a speed of 10g / min, the mass concentration of the wall materials (gum arabic and chitosan) is 2.5%, and the ratio of the core material to the wall material is 1:4. fourth solution.

[0066] 5. Coagulation: Add dilute hydrochloric acid to the fourth solution to adjust the coagulation pH to 4.2; put it in an ice-wat...

Embodiment 2

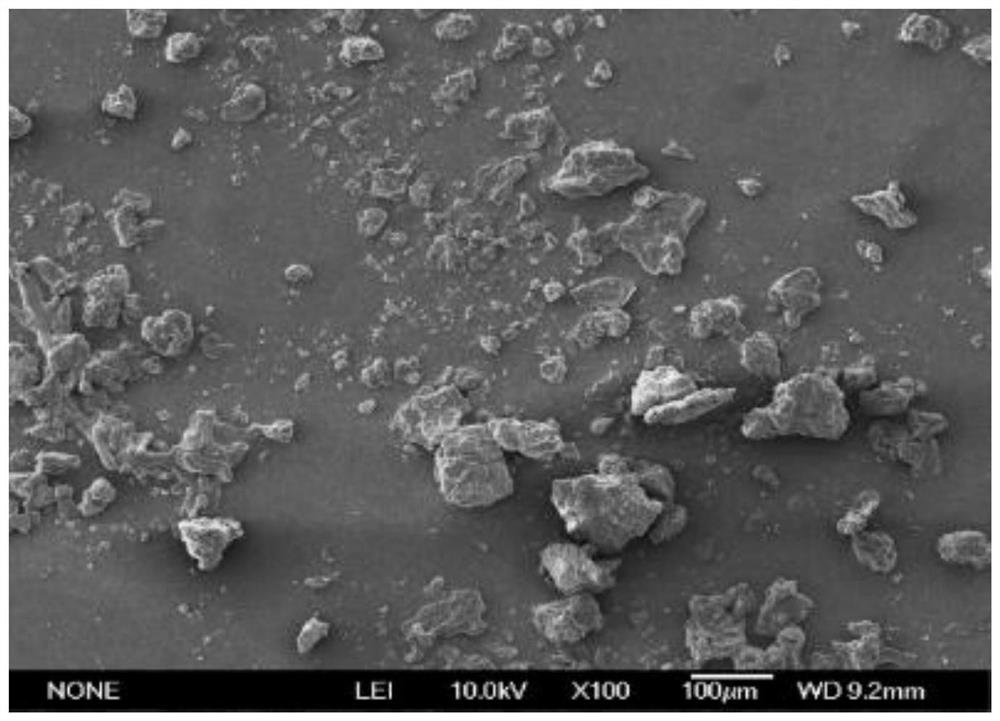

[0129] The yield and encapsulation efficiency of Eucommia ulmoides seed oil microcapsules obtained in Example 1 and Comparative Examples 1-17 were determined.

[0130] 1,

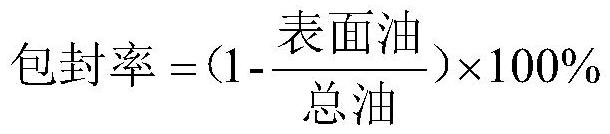

[0131] 2. Encapsulation efficiency: full scan to find the maximum wavelength of eucommia seed oil, establish a standard curve of eucommia seed oil at this wavelength, surface oil: take 0.5g microcapsules, add 5mL n-hexane to dissolve, centrifuge at 7000rpm for 5min, and take the supernatant The absorbance of the solution at the lower side of the maximum wavelength was brought into the standard curve to calculate the concentration. Total oil: Take 0.5g of microcapsules, add 5mL of n-hexane to dissolve, fully dissolve in a shaker for 12h, then sonicate for 1h, centrifuge at 7000rpm for 20min, take the absorbance of the supernatant at the lower side of the maximum wavelength, and bring it into the standard curve to calculate the concentration.

[0132]

[0133] See Tables 1 to 5 for the measurement resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com