Oil shale particle crushing device based on ultrasonic waves

A crushing device and ultrasonic technology, applied in the field of oil shale pyrolysis, can solve the problems of incomplete crushing, large wear, slow speed, etc., and achieve the effect of optimizing particle crushing effect, reducing mechanical energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

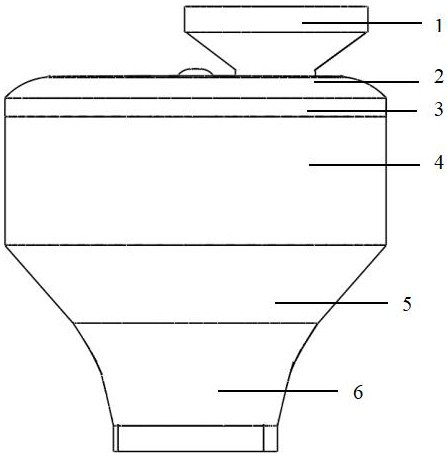

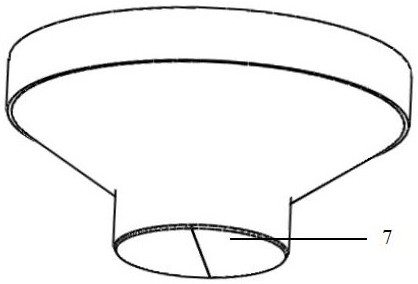

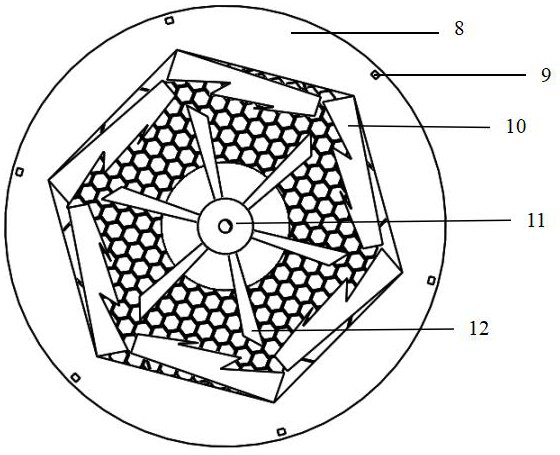

[0030] How it works: combining Figure 1-Figure 11 As shown, this ultrasonic-based oil shale particle crushing device includes a massive oil shale inlet 1, an acoustic wave generator collection bin 3, an ultrasonic combined high-frequency cutting tooth crushing bin 4, and an oil shale particle storage bin 5 , the oil shale particle "V" shaped discharge area 6; the lower part of the oil shale inlet 1 is connected to the fixed protective shell 2 of the crushing chamber, and the opening and closing dustproof baffle 7 is placed directly at the lower end of the inlet 1, and the feeding operation process The dust removal baffle 7 is opened, and the dust removal baffle 7 is automatically closed after feeding; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com