Preparation method and application of low-cost high-purity polymelamine

A kind of polymelamine, melamine technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

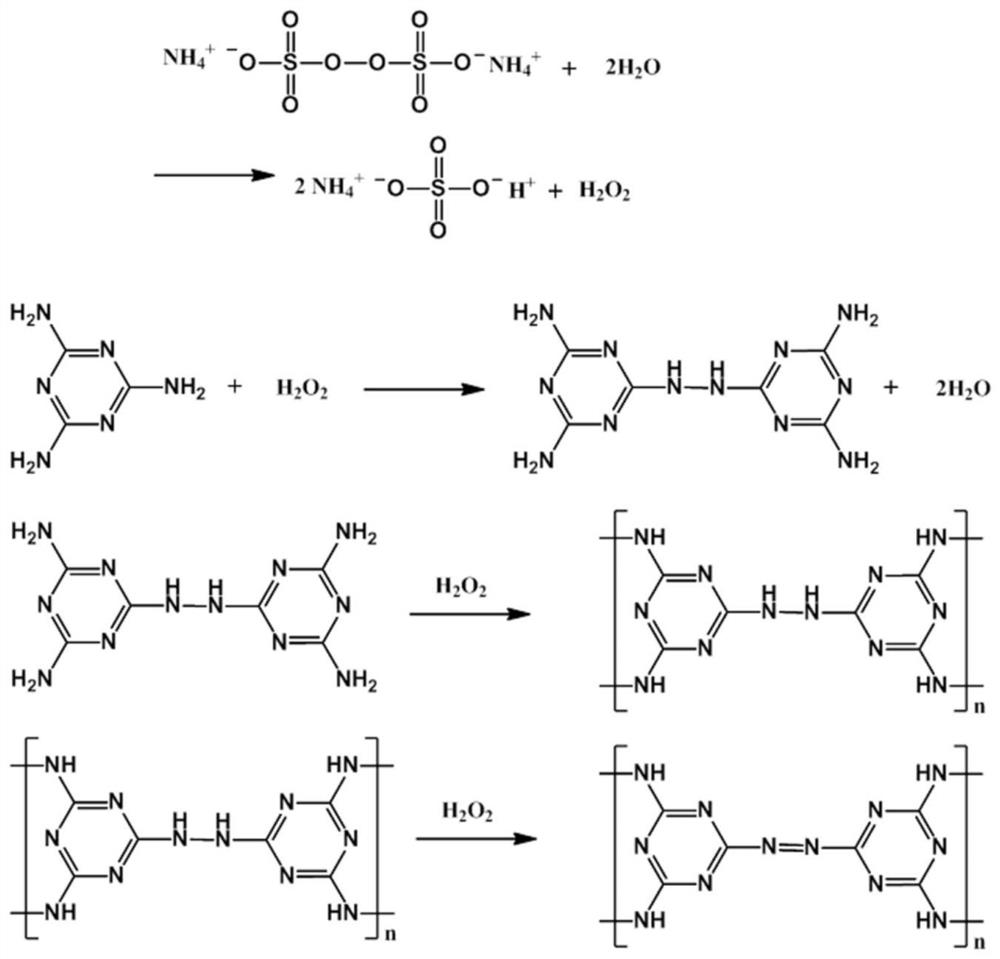

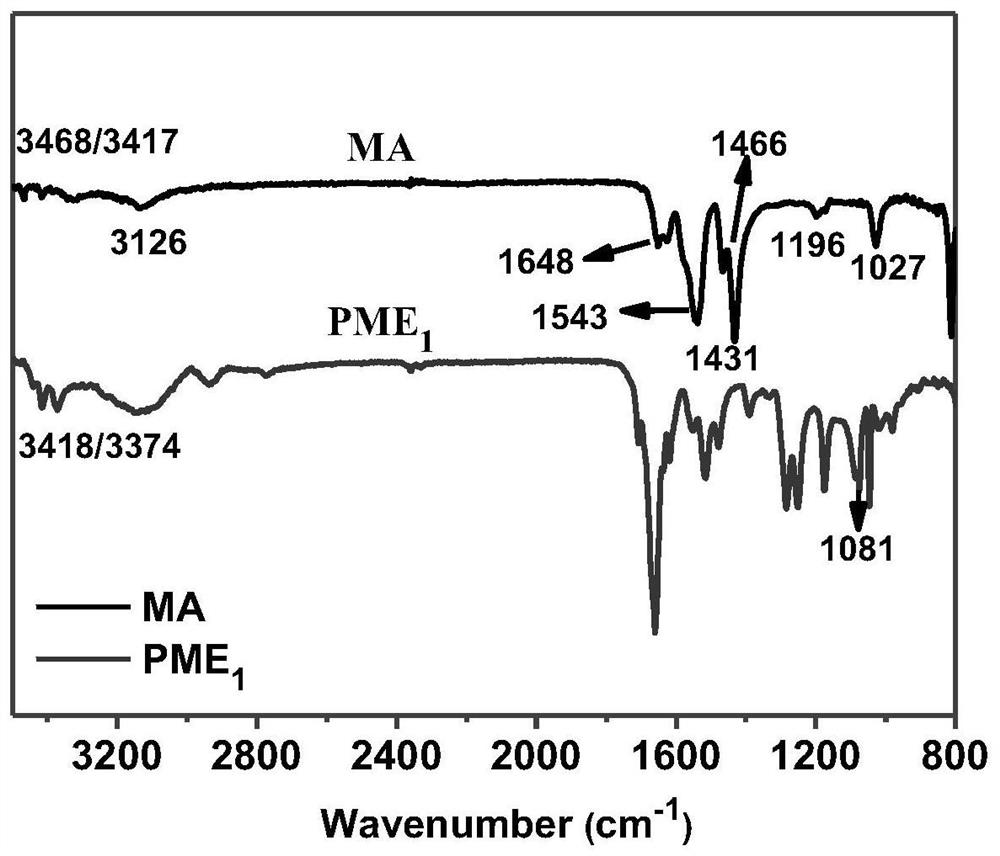

Method used

Image

Examples

Embodiment 1

[0041] 1) Add 0.61g (4.8mmol) melamine (MA) to phytic acid (PA) of 10mL, and use ultrasonic treatment to promote the dissolution of MA in PA until a light yellow transparent solution is formed to obtain solution A, and then Solution A was placed in an ice-water bath for 30 min.

[0042] 2) Dissolve 3.86g (16.9mmol) of ammonium persulfate in 5mL of deionized water to obtain solution B, and then place solution B in an ice-water bath for 30min.

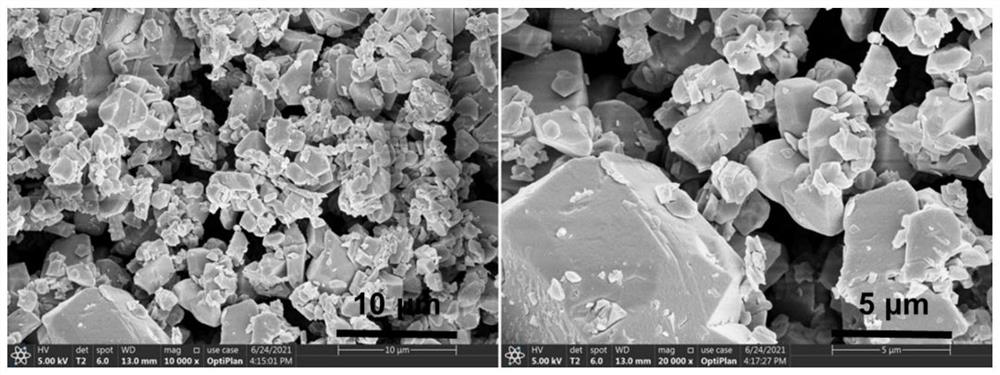

[0043] 3) Under the condition of an ice-water bath, bubble argon into solution A for 10 minutes, then add solution B dropwise to solution A at a rate of 1 drop / second, after solution B is completely added to solution A, put The obtained mixed solution continued to stir for 30 minutes, and the solid product was collected by filtration, and then the solid product was washed with deionized water for several times until the pH value of the washing solution was 7, and finally the product was freeze-dried and stored, and the product was named ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com