Blast furnace molten iron silicon content online prediction method and system based on deep migration network

A blast furnace molten iron and prediction method technology, applied in biological neural network model, computer-aided design, design optimization/simulation, etc., can solve the problem of low accuracy of online prediction of silicon content in blast furnace molten iron, achieve efficient and accurate prediction, reduce dependence, Solve the effect of low online prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

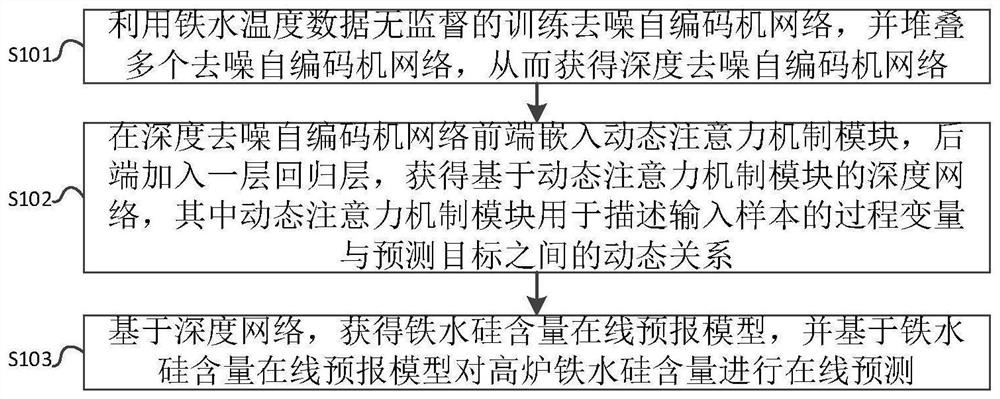

[0060] refer to figure 1 , the method for online prediction of silicon content in blast furnace molten iron based on deep migration network provided by Embodiment 1 of the present invention includes:

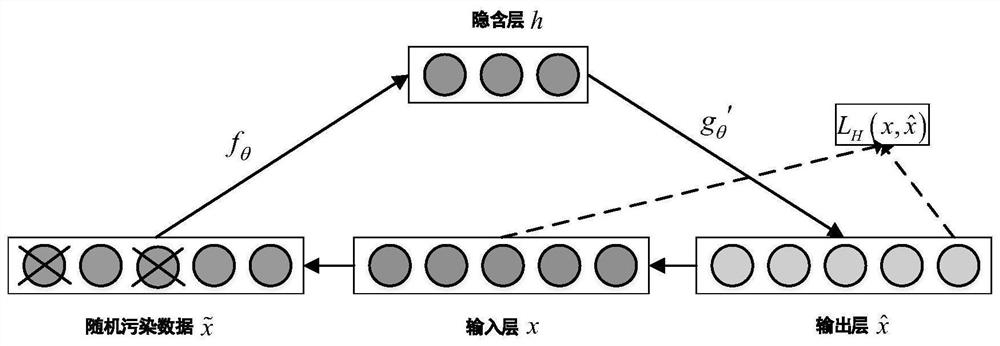

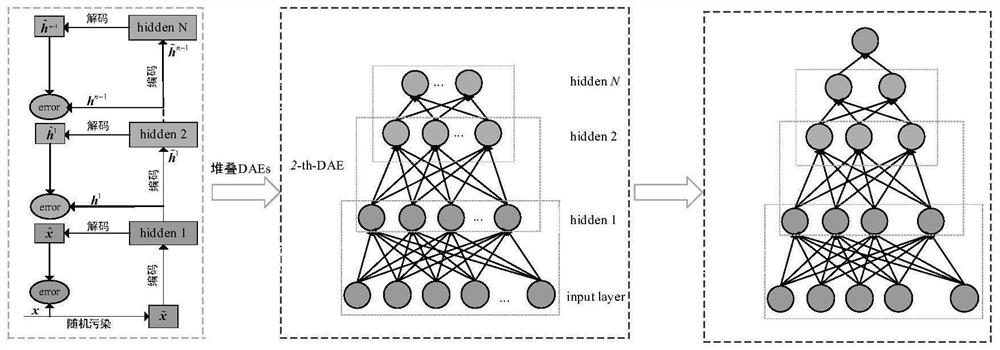

[0061] Step S101, using the molten iron temperature data to unsupervisedly train the denoising autoencoder network, and stacking multiple denoising autoencoder networks to obtain a deep denoising autoencoder network;

[0062] Step S102, embedding a dynamic attention mechanism module in the front end of the deep denoising autoencoder network, and adding a layer of regression layer in the back end to obtain a deep network based on the dynamic attention mechanism module, wherein the dynamic attention mechanism module is used to describe the input sample The dynamic relationship between the process variable and the predicted target;

[0063] Step S103, based on the deep network, an online prediction model for the silicon content of the molten iron is obtained, and based on the onli...

Embodiment 2

[0066] The method for online prediction of silicon content in blast furnace molten iron based on deep migration network provided by Embodiment 2 of the present invention includes:

[0067] Step S201, collecting historical data of the blast furnace and performing preprocessing on the historical data of the blast furnace. The preprocessing includes time registration of input and output samples, elimination of abnormal data, normalization processing and variable correlation analysis.

[0068] Specifically, a large amount of historical data is stored in the historical database of the blast furnace, but due to various reasons such as equipment failure or manual operation errors during the collection process, the data cannot truly and accurately reflect the furnace conditions, so the data needs to be preprocessed to Eliminate the above problems and improve the quality of data to build a high-quality data set. Specific steps are as follows:

[0069] (1) Input and output sample time ...

Embodiment 3

[0125] refer to Figure 7 , the embodiment of the present invention provides an online method for predicting the silicon content of blast furnace molten iron based on a deep migration network, taking a 2650m 3 Large-scale blast furnace verification, specifically including the following steps:

[0126] 1) Data preprocessing. Correlation processing is carried out on the data collected on the blast furnace detection device to improve the quality of the data. In this embodiment, the data from August 1, 2020 to December 17, 2020 in the blast furnace historical database are obtained, in which there are 1,160,141 groups of process variables, There are 172,352 sets of molten iron temperature data, and 7,282 sets of silicon content data, including input and output sample time registration, abnormal data processing, normalization processing, and feature selection based on the maximum mutual information coefficient. After processing, there are 111,041 sets of molten iron temperature dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com