Molecular sieve adsorption energy-saving system

An energy-saving system and molecular sieve technology, applied in separation methods, dispersed particle separation, gas treatment, etc., can solve the problem of large steam consumption of molecular sieve adsorption devices, and achieve the effect of saving steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

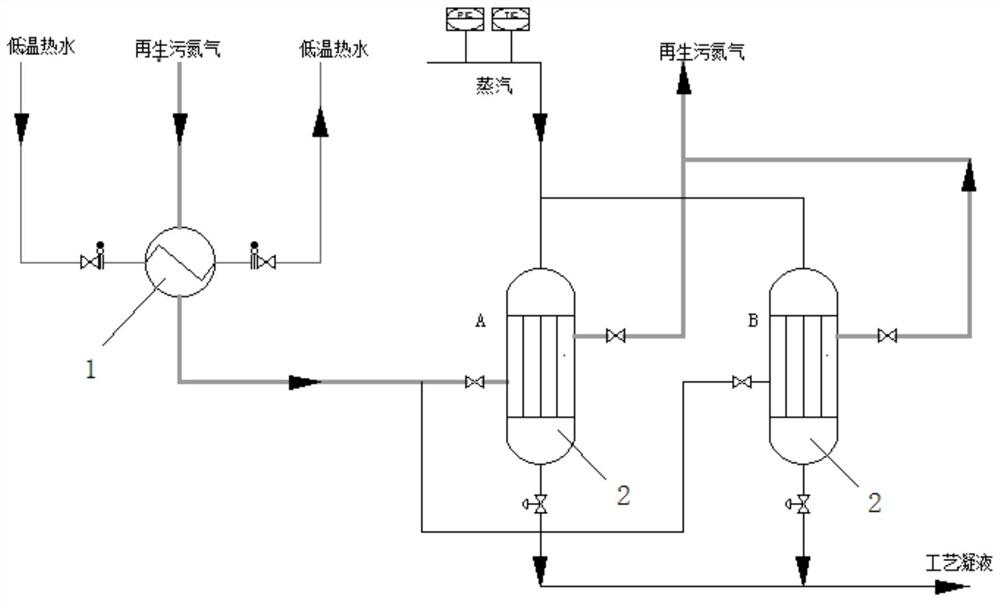

[0024] like figure 1 As shown, the present invention provides a molecular sieve adsorption energy-saving system, comprising sequentially connected preheaters, two steam heaters operating in parallel, and a molecular sieve adsorber;

[0025] The steam heater includes a regeneration gas inlet, a regeneration gas outlet, a steam inlet and a steam outlet; the preheater includes a gas side inlet, a gas side outlet, a water side inlet and a water side outlet, and the gas side outlet is connected to the The regeneration gas inlet of the steam heater, the regeneration gas outlet of the steam heater is connected to the molecular sieve adsorber;

[0026] The regenerated dirty nitrogen gas is first passed into the pre-heater to be heated by low-temperature hot water, then passed into the steam heater to be heated by steam, and finally passed into the molecular sieve adsorber for exothermic analysis and then emptied.

[0027] Further, the low-temperature hot water is passed into the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com