Double-spindle symmetrical type grinding machining device

A grinding, symmetrical technology, applied in the field of grinding, can solve the problems of low work efficiency, the grinding machine fixture cannot meet the needs of production, and high processing costs, and achieve the effect of avoiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

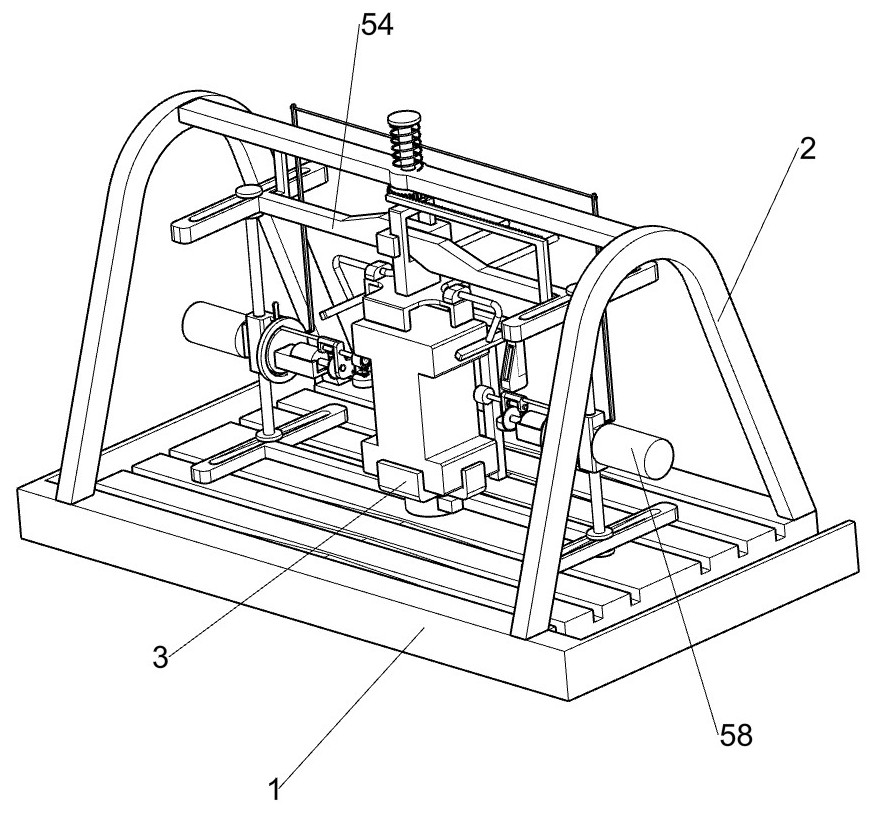

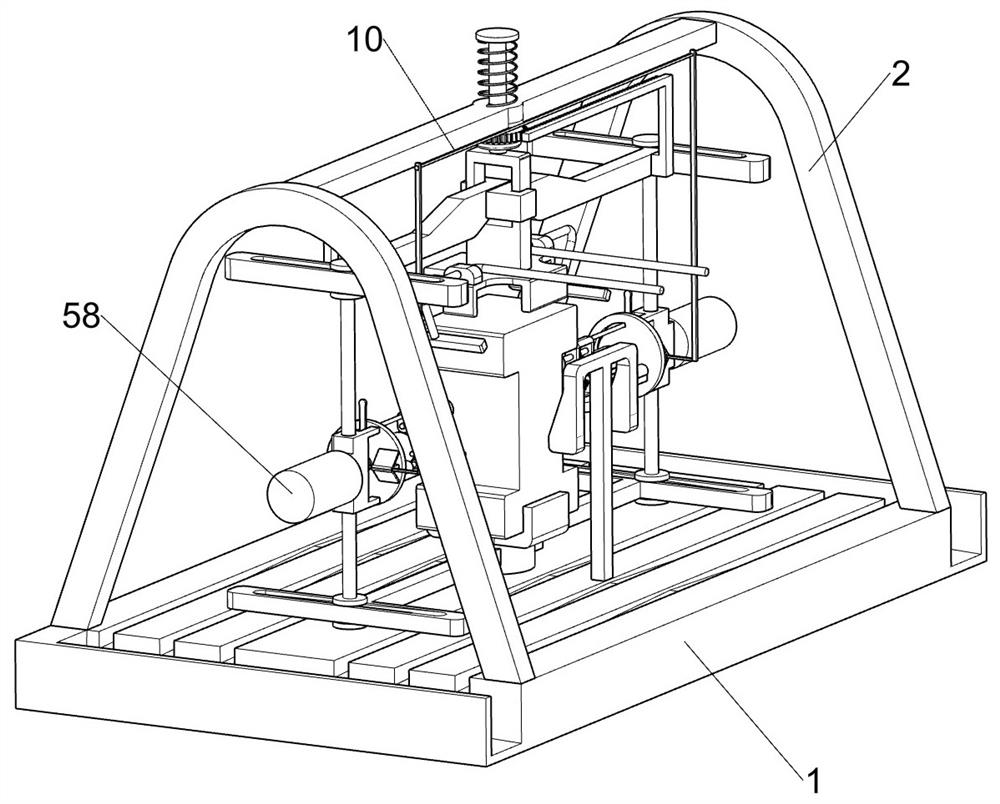

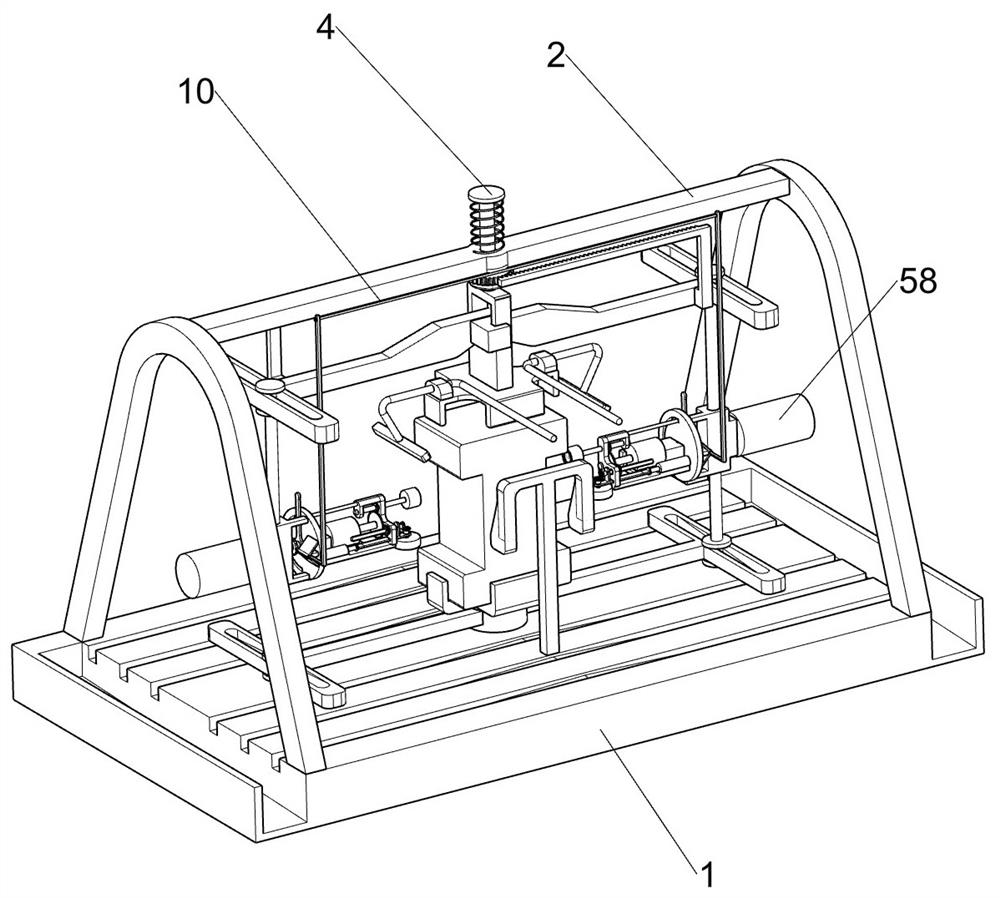

[0034] Symmetrical two-spindle grinding apparatus, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 Shown, comprising a bottom machining housings 1, the support frame 2, the bottom clamping holder 3, the lifting rod 4, moved towards the fixed assembly 5, 6 and the clamping assembly adjustment work-piece assembly 7 front grinding, machining the bottom groove a support frame with a surface of the base 2 is fixedly mounted, the bottom portion for placing a workpiece holder 3 is fixed tightly attached to the middle of processing a bottom surface of the groove base, the lifting rod 4 is slidably connected to the support frame 2, the bottom clamping seat 3 the sliding connection has moved towards the fixed assembly 5, 5 move towards each fixing assembly for securing a work piece, provided with a clamping facing adjustment assembly 6, 6 clamping adjustment assembly for adjusting the working position of the mo...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 10 Shown, further comprises a work-piece side grinding assembly 8, is provided with adjustment work-shaped member on the stem side grinding assembly 628, grinding work-piece side component 8 for abrasive machining a workpiece side surface , - shaped member 8 side grinding assembly 81 comprises a rotating ring gear, the guide shaft 82, the moving plate 83, the machine axis 831, bevel gear 84, the push rod 85 and the second electric processing wheel 86, the adjusting lever 62 is rotated formula connected to a rotating ring gear 81, the ring gear 74 engaged with the rotating force of the gear 81 with each other, the rotation of the ring gear 81 slidably connected to a guide shaft 82, driven by an electric adjustable telescopic rod 62 is fixedly mounted on the pusher 85, the pusher motor 85 telescopic shaft end welded moving plate 83, the guide shaft 82 and the moving plate 83 rotary connector, the movable plate 83 and 62 slidably conne...

Embodiment 3

[0045] On the basis of Example 2, such as Figure 11 , Further includes a cooling liquid supply assembly 9, the top of the clamping holder with a coolant supply arranged symmetrically assembly 539, the coolant supply unit 9 for cooling the workpiece, the coolant supply assembly 9 comprises a mounting block 91, 92 bottom end of the coolant tube 92, the nozzle 93 and the fixed head holder 94, symmetrically fixed to a mounting block 91 on the top clamp seat 53, is mounted on a cooling block 91 is fixed to the liquid pipe 92 for conveying the cooling liquid, the cooling liquid pipe fixed for the cooling liquid discharge nozzle 93, a middle bottom face machining housings fixedly connected with a seat for fixing the discharge nozzle 94 of the cooling liquid.

[0046] Coolant tube 92 and fixed to the head holder 94 is connected pipes in the large-scale processing equipment, the coolant pipes of the coolant delivery tube 92, a top clamp seat 53 carrying the mounting block 91 downwardly and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com