Anti-yellowing salt-fog-resistant polyamide-imide resin composition as well as preparation method and application thereof

A polyamide-imide resin, polyamide-imide technology, applied in coatings, anti-corrosion coatings, etc., can solve the problem of reducing the service life of polyamide-imide resin, yellowing, and damage to polyamide-imide resin products and other problems, to achieve the effect of enhancing comprehensive mechanical properties, high salt spray resistance, and improving service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

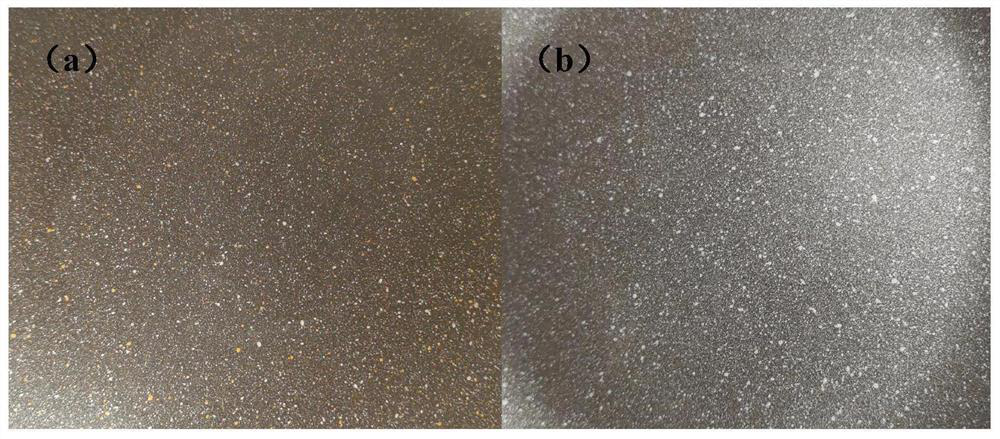

Image

Examples

Embodiment 1

[0030] Preparation of Waterborne Polyamideimide Resin

[0031] Put 785.5g of trimellitic anhydride, 1027.9g of diphenylmethane-4,4'-diisocyanate, and 2216.4g of N-methylpyrrolidone into the stirring reactor, and slowly raise the temperature for 1 hour while stirring in a dry nitrogen flow, and the to 120°C. 140 degreeC was maintained, and heating was continued for 3 hours in this state. Subsequently, the temperature was lowered to 85° C., a mixed solution of 576.1 g of dimethylethanolamine and 1942.5 g of pure water was added, and kept for 2 hours to obtain a water-based polyamide-imide resin, which was designated as A1.

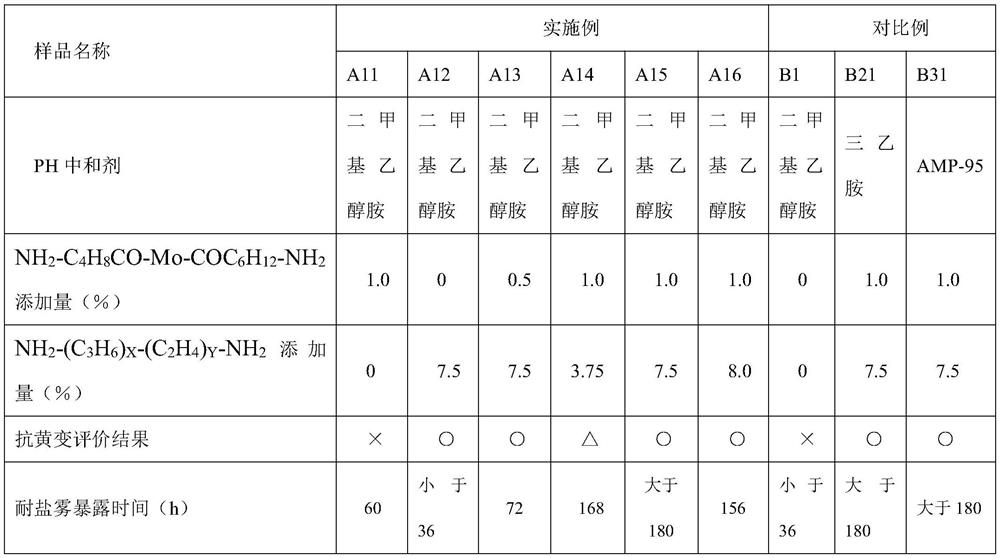

[0032] Modified polyamideimide resin

[0033] 1,000 g of the obtained aqueous polyamide-imide resin solution (A1) was charged into a stirring reactor, and the temperature was gradually raised to 80° C. while stirring in a dry nitrogen flow. After reaching 80°C, slowly add 10.0g NH while stirring at 80°C 2 -C 4 h 8 CO-Mo-COC 6 h 12 -NH 2 (MW=2600), t...

Embodiment 2

[0035] 1000 g of the aqueous polyamide-imide resin solution (A1) obtained in Example 1 was charged into a stirring reactor, and the temperature was gradually raised to 80° C. while stirring in a dry nitrogen flow. After reaching 80°C, slowly add 75.0g NH while stirring at 80°C 2 -(C 3 h 6 ) X -(C 2 h 4 ) Y -NH 2 (MW=3000), the dropping time was 7 minutes and 30 seconds, and the aqueous polyamide-imide resin composition A12 was obtained after 60 minutes of heat preservation.

Embodiment 3

[0037] 1000 g of the aqueous polyamide-imide resin solution (A1) obtained in Example 1 was charged into a stirring reactor, and the temperature was gradually raised to 80° C. while stirring in a dry nitrogen flow. After reaching 80°C, keep stirring at 80°C and slowly add 5.0g NH 2 -C 4 h 8 CO-Mo-COC 6 h 12 -NH 2 (MW=2600) and 75.0gNH 2 -(C 3 h 6 ) X -(C 2 h4 ) Y -NH 2 (MW=3000) mixed solution, the dropwise addition time was 8 minutes, and the water-based polyamide-imide resin composition A13 was obtained after 60 minutes of heat preservation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com