Aluminum-silicon target material and preparation method thereof

An aluminum-silicon target and leveling technology, applied in the field of magnetron sputtering, can solve the problems of inability to realize large-scale production, high requirements for production equipment, and insufficient grain refinement, so as to improve the uniformity of thickness distribution and avoid deformation and crack tendency, the effect of internal grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

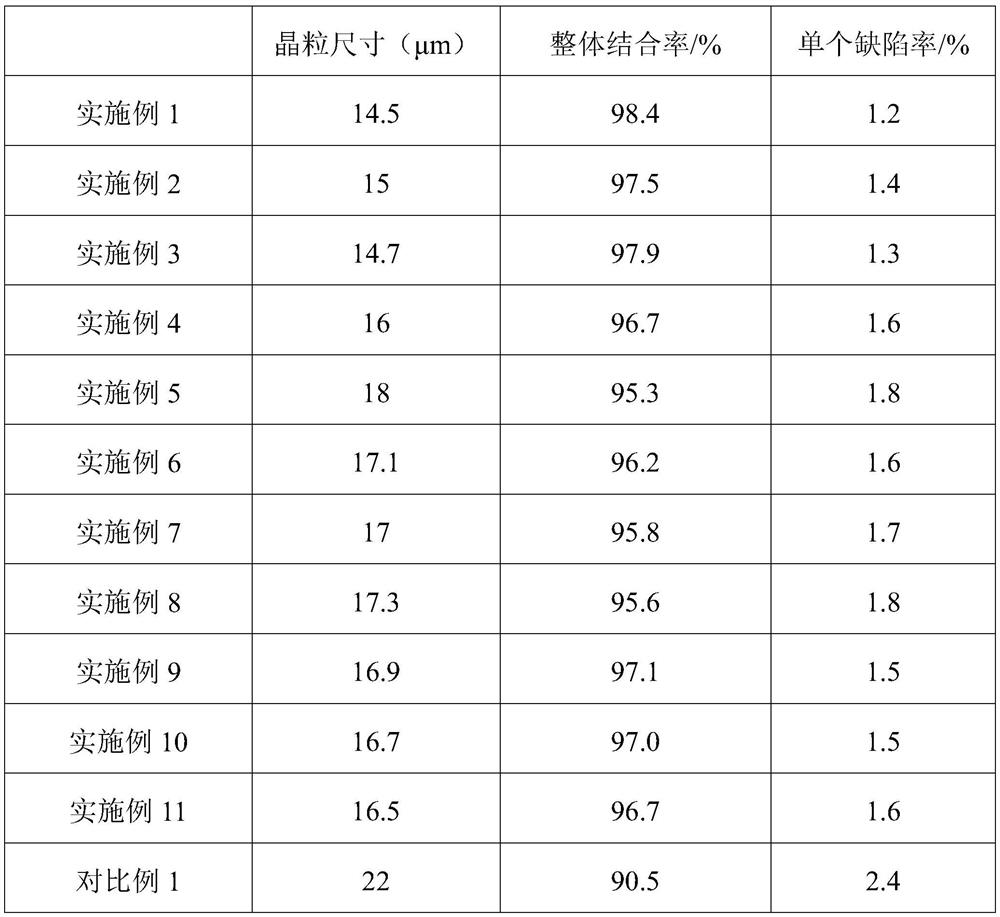

Examples

Embodiment 1

[0055] This embodiment provides an aluminum-silicon target and its preparation method, the preparation method comprising the following steps:

[0056] (1) First forging: preheating at 150°C, stretching to 195% of the original length of the aluminum-silicon target blank, and then water cooling;

[0057] (2) The first heat treatment: heat treatment at 490°C for 15 minutes, and then water cooling;

[0058] (3) Second forging: Preheat at 150°C, thicken to 105% of the original length of the aluminum-silicon target blank, and stretch to 195% of the original length of the aluminum-silicon target blank, and then water-cool;

[0059] (4) Second heat treatment: heat treatment at 390°C for 15 minutes, and then water cooling;

[0060] (5) Pressing: the first pressing to 50% of the original length of the aluminum-silicon target blank; the second pressing to 40% of the original length of the aluminum-silicon target blank;

[0061] (6) The third heat treatment: heat treatment at 350°C for ...

Embodiment 2

[0065] This embodiment provides an aluminum-silicon target and its preparation method, the preparation method comprising the following steps:

[0066] (1) First forging: preheating at 140°C, stretching to 180% of the original length of the aluminum-silicon target blank, and then water cooling;

[0067] (2) The first heat treatment: heat treatment at 485°C for 20 minutes, and then water cooling;

[0068] (3) Second forging: Preheat at 140°C, thicken to 100% of the original length of the aluminum-silicon target blank, and stretch to 185% of the original length of the aluminum-silicon target blank, and then water-cool;

[0069] (4) Second heat treatment: heat treatment at 385°C for 20 minutes, and then water cooling;

[0070] (5) Pressing: the first pressing to 45% of the original length of the aluminum-silicon target blank; the second pressing to 35% of the original length of the aluminum-silicon target blank;

[0071] (6) The third heat treatment: heat treatment at 345°C for ...

Embodiment 3

[0075] This embodiment provides an aluminum-silicon target and its preparation method, the preparation method comprising the following steps:

[0076] (1) First forging: Preheat at 160°C, stretch to 210% of the original length of the aluminum-silicon target blank, and then water-cool;

[0077] (3) The first heat treatment: heat treatment at 495°C for 10 minutes, and then water cooling;

[0078] (4) Second forging: Preheat at 160°C, thicken to 110% of the original length of the aluminum-silicon target blank, and stretch to 205% of the original length of the aluminum-silicon target blank, and then water-cool;

[0079] (5) Second heat treatment: heat treatment at 395°C for 10 minutes, and then water cooling;

[0080] (6) Pressing: the first pressing to 55% of the original length of the aluminum-silicon target blank; the second pressing to 45% of the original length of the aluminum-silicon target blank;

[0081] (7) The third heat treatment: heat treatment at 355°C for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com