Paper diaper core manufacturing process

A diaper and core technology, which is applied in the field of disposable hygiene products, can solve the problems of thick products, easy agglomeration and breakage, etc., and achieves the effects of low production cost, large effective absorption area, and improved utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

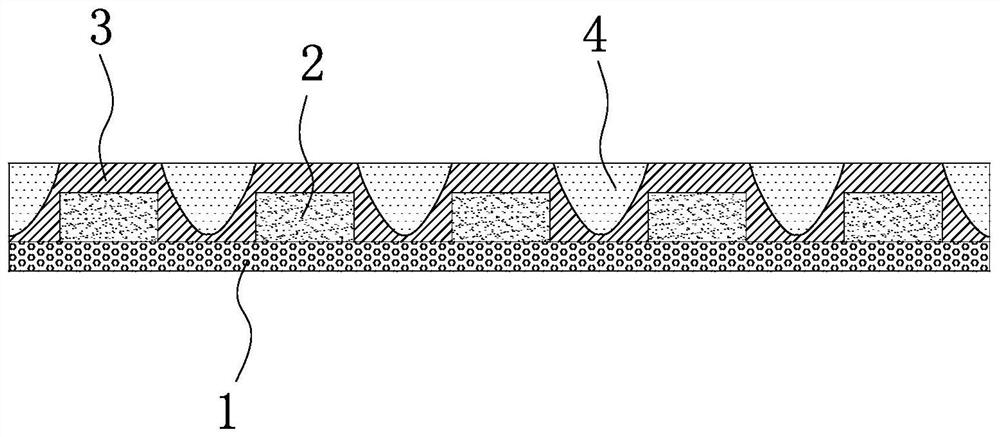

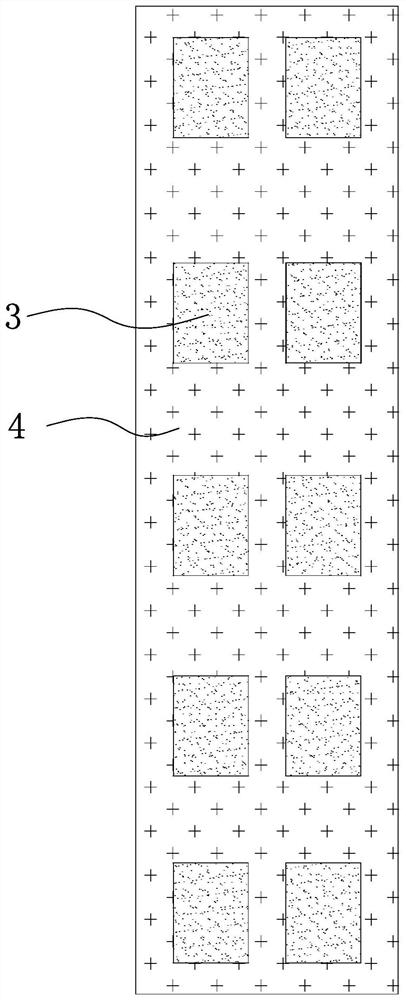

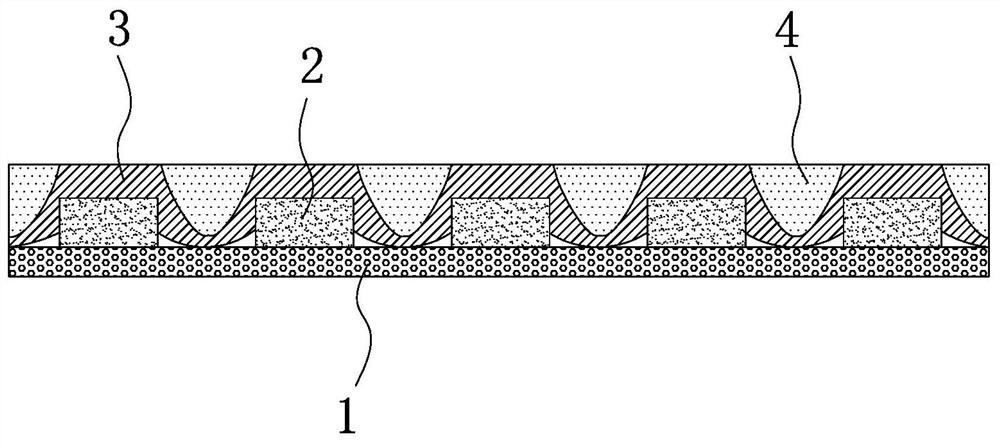

[0030] refer to Figure 1 to Figure 5 , the present embodiment provides a diaper core manufacturing process, comprising the following steps:

[0031] (1) Manufacture of the first core layer: the bottom non-woven fabric 1 is transported to the first mold wheel, the outer edge of the first mold wheel is provided with an adsorption template, and the adsorption template is provided with a positive integer number of modules, polymer materials Sprinkle on the first mold wheel, the module on the first mold wheel has negative pressure, and the bottom non-woven fabric 1 enters the mold wheel adsorption plate before the polymer material is sprinkled on the first mold wheel, and the module will be absorbed by the adsorption force. The polymer material is adsorbed and adhered to the bottom non-woven fabric, and the polymer material on each module forms a first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com