Ceramic dry granular glaze, crystal diamond flash ceramic tile and preparation methods of ceramic dry granular glaze and crystal diamond flash ceramic tile

A dry glaze and ceramic tile technology, applied in the field of architectural ceramics, can solve the problems of melting, flashing mica flashing effect reduction, glaze flashing effect discounting, etc., to prevent micro-crack defects, ensure flashing effect, and improve antifouling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

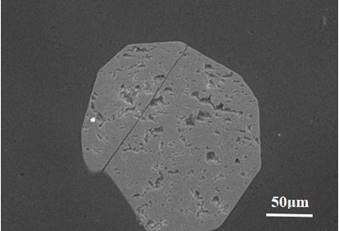

Image

Examples

Embodiment 1

[0055] A dry ceramic glaze, the raw material composition of which includes zirconium-containing transparent frit dry particles and zircon sand, wherein: the mass ratio of zirconium-containing transparent frit dry particles to zircon sand is 95:5; zirconium-containing transparent frit dry particles The chemical composition of the pellets includes 53.57% SiO by weight percent 2 , 17.92% Al 2 o 3 , 0.20% Fe 2 o 3 , 0.03% TiO 2 , 13.92% CaO, 2.47% MgO, 1.16% ZnO, 1.86% K 2 O, 6.13% Na 2 O, 0.85% ZrO 2 , 1.89% loss on ignition, and the zirconium source of zirconium-containing transparent frit dry particles is zirconium oxychloride, and the particle size of zirconium-containing transparent frit dry particles is 120 mesh sieves; the purity of zircon sand is 96wt%, zirconium The particle size of British sand is 120 mesh sieve.

[0056] A preparation method of ceramic dry glaze, comprising the following steps:

[0057] (1) According to the ratio of raw materials, mix zirconium...

Embodiment 2

[0069] A kind of ceramic dry glaze, its raw material composition includes zirconium-containing transparent frit dry particles and zircon sand, wherein: the mass ratio of zirconium-containing transparent frit dry particles to zircon sand is 97:3; zirconium-containing transparent frit dry particles The chemical composition of the pellets includes 48.80% SiO by weight 2 , 19.71% Al 2 o 3 , 0.22% Fe 2 o 3 , 0.03% TiO 2 , 15.31% CaO, 2.71% MgO, 1.28% ZnO, 2.05% K 2 O, 6.74% Na 2 O, 1.05% ZrO 2 , 2.10% loss on ignition, and the zirconium source of zirconium-containing transparent frit dry particles is zirconium oxychloride, and the particle size of zirconium-containing transparent frit dry particles is 120 mesh sieves; the purity of zircon sand is 97wt%, zirconium The particle size of British sand is 100 mesh sieve.

[0070] A preparation method of ceramic dry glaze, comprising the following steps:

[0071] (1) According to the ratio of raw materials, mix zirconium oxychlor...

Embodiment 3

[0082] A kind of ceramic dry glaze, its raw material composition includes zirconium-containing transparent frit dry particles and zircon sand, wherein: the mass ratio of zirconium-containing transparent frit dry particles to zircon sand is 94:6; zirconium-containing transparent frit dry particles The chemical composition of the pellets includes 58.42% SiO by weight percent 2 , 16.12% Al 2 o 3 , 0.18% Fe 2 o 3 , 0.04% TiO 2 , 12.53% CaO, 2.22% MgO, 1.04% ZnO, 1.67% K 2 O, 5.51% Na 2 O, 0.55% ZrO 2, 1.72% loss on ignition, and the zirconium source of zirconium-containing transparent frit dry particles is zirconium oxychloride, and the particle size of zirconium-containing transparent frit dry particles is 100 mesh sieves; the purity of zircon sand is 97wt%, zirconium The particle size of British sand is 100 mesh sieve.

[0083] A preparation method of ceramic dry glaze, comprising the following steps:

[0084] (1) According to the ratio of raw materials, mix zirconium o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com