Digital twin behavior constraint method and system for TPM equipment management

A device management and digital technology, applied in the computer field, can solve problems such as stagnation, inability to manage TPM device lifecycle constraints, and data isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

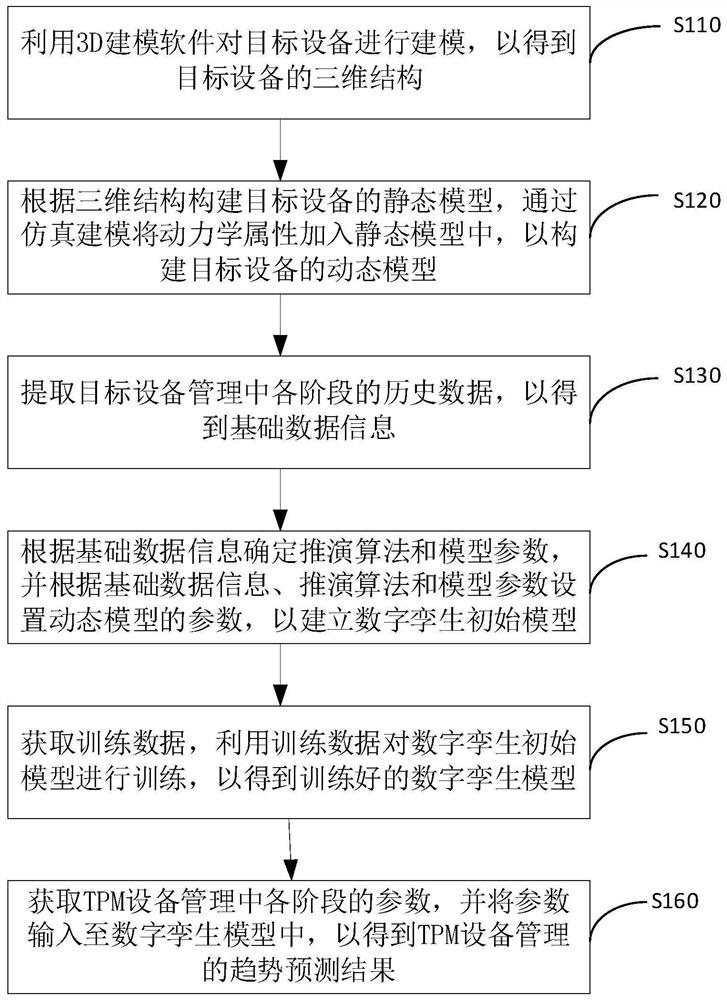

[0033] Please refer to figure 1 , figure 1 Shown is a flow chart of a digital twin behavior constraint method for TPM device management provided by an embodiment of the present application. A digital twin behavior constraint method for TPM equipment management, comprising the steps of:

[0034] S110: Using 3D modeling software to model the target device to obtain a three-dimensional structure of the target device;

[0035] Exemplarily, the above-mentioned 3D modeling software can adopt SolidWorks or AutoCAD. Then SolidWorks or AutoCAD can be used to model the shape of the target device, so as to obtain the three-dimensional structure of the target device. The three-dimensional structure can reflect the appearance characteristics of the target device.

[0036] S120: Construct a static model of the target device according to the three-dimensional structure, and add dynamic properties to the static model through simulation modeling to construct a dynamic model of the target d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com