Level set mask optimization method for distance regular level set and convolutional neural network

A technology of convolutional neural network and optimization method, applied in the field of chip manufacturing, which can solve the problems of limited quality and time-consuming reticle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In one embodiment, the technical terms of the present invention illustrate:

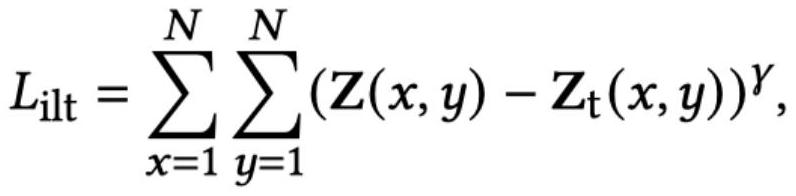

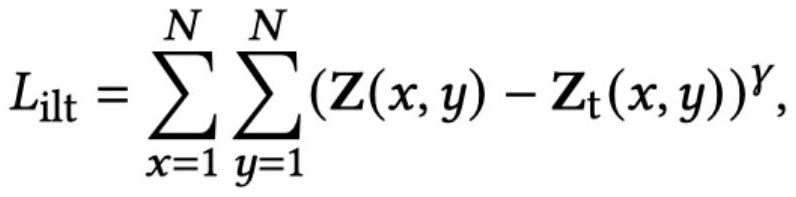

[0019] 1) Modeling of lithography model and inverse lithography technology

[0020] According to the forward lithography model, a printed pattern can be obtained based on a given mask. This includes two models: the lithography projection model and the photoresist model. The lithographic projection model can be described as an operation between the lithographic kernel and the mask. The photoresist model determines the actual printed shape by judging whether the transmitted light intensity exceeds the threshold.

[0021] 2) Accurate Margin Error

[0022] The distortion of the printed graphics is continuous, and the generated graphics distortion part only contains protrusions or depressions. Insert a large number of detection points on the outline of the target pattern, and calculate the vertical distance between the target outline at the detection points and the actual printed image (perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com