Device and method for rapidly reducing dissolved oxygen in cooling water of generator stator

A generator stator and cooling water technology, which is applied in the field of nuclear power, can solve the problems of generator hollow copper wire corrosion, complicated operation, electrochemical corrosion, etc., and achieve the effects of reducing related industrial safety risks, avoiding safety risks, and simplifying personnel operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

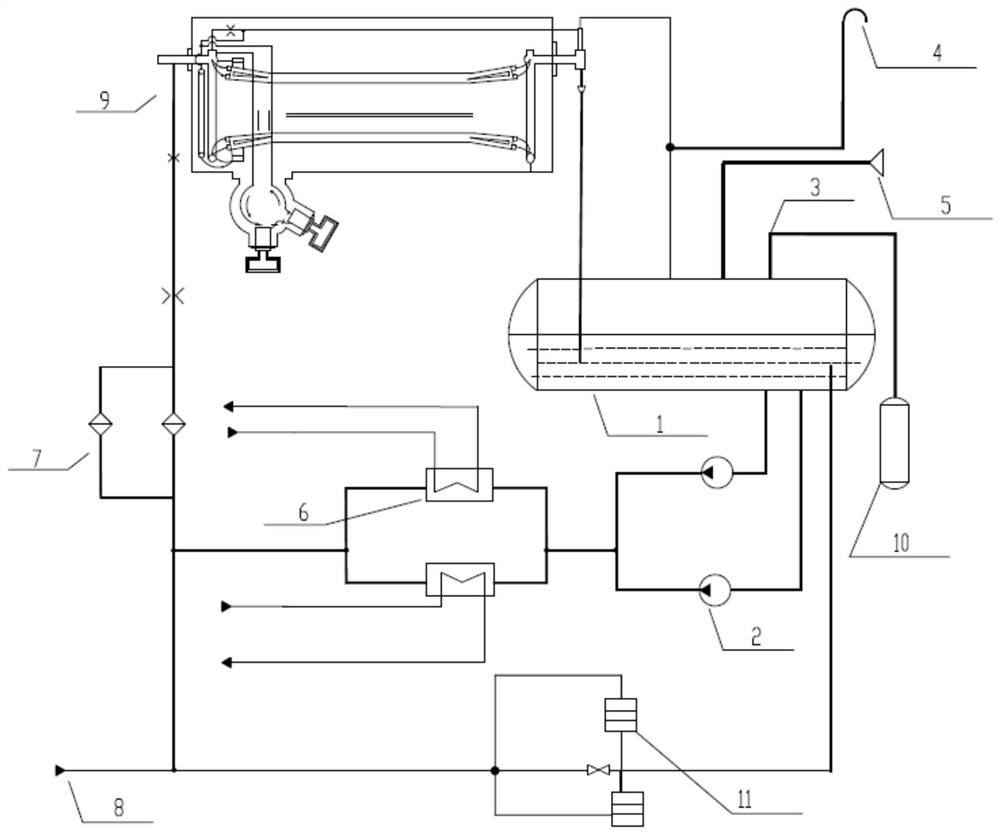

[0045] Such as figure 1 As shown, the improved device for quickly reducing the dissolved oxygen in the generator stator cooling water includes a generator stator cooling water tank 1, a generator stator cooling water pump 2 connected to the outlet of the lower part of the generator stator cooling water tank 1 through pipelines, and a demineralized water source 8 , the generator 9 connected to the upper inlet of the generator stator cooling water tank 1 through a pipeline; the collector ring side of the generator 9 is connected to the desalted water source 8 through a pipeline, and two parallel filters 7 are installed on the pipeline;

[0046] Among them, two parallel ion filters 11 are installed on the pipeline between the desalinated water source 8 and the generator stator cooling water tank 1. There are two generator stator cooling water pumps 2, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com