Three-axis numerical control head-to-head boring machine and machining process

A technology of head-to-head and boring, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of unprotected surface, roughness, low dimensional accuracy, etc., to improve the surface finish and dimensional accuracy, reduce chatter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

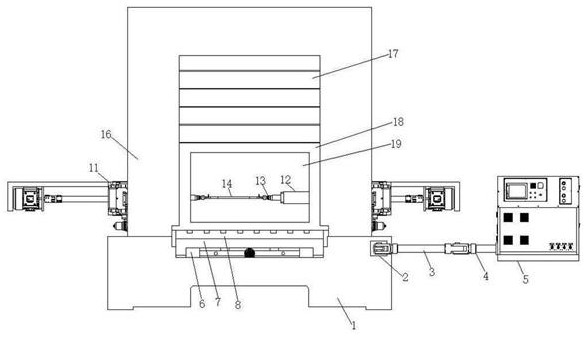

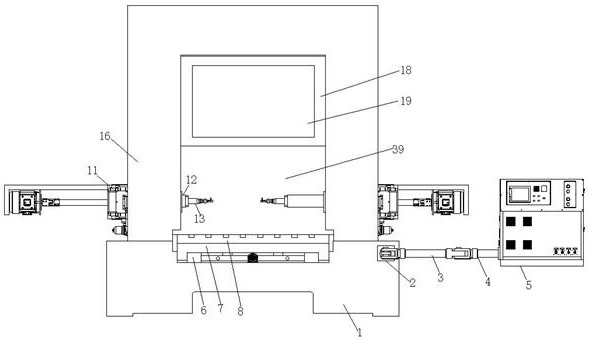

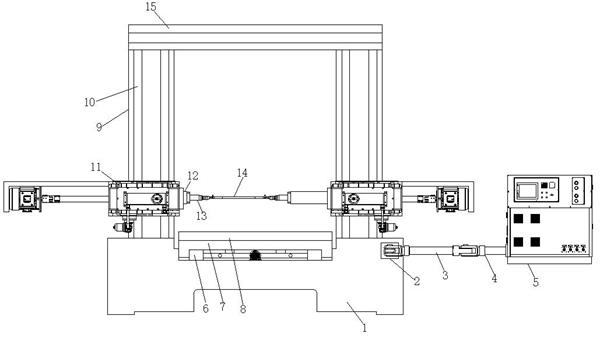

[0044] like Figure 1 to 15 As shown, the embodiment of the present invention provides a three-axis number of control to the head boring, including the bed 1; rotating the control tank 5 connected to the bed 1 through the fold arm assembly, the folding arm assembly includes a rotating seat 2, the first fold arm 3, The second folding arm 4, the rotating seat 2 is fixedly connected to the front wall of the bed 1 and close to the right side wall, and the first fold arm 3 rotates to be connected to the front wall of the rotating seat 2, the second fold arm 4 rotates in the first fold arm 3 Keep away from one end of the rotating seat 2, the second fold arm 4 is fixedly connected to the control box 5 from one end of the first fold arm 3, and by the folding arm assembly, the control box 5 can be convenient to the front-rear and rear, left and right, for use; As a column 9, the two sets of column 9 are fixed to the left and right distribution, and the upper end of the bed 1 is fixed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com