Novel 700 DEG C ultra-supercritical pi-type corner tangential combustion boiler structure

An ultra-supercritical, four-corner tangent technology, which is applied in the field of boiler combustion, can solve problems such as temperature deviation at the furnace outlet, and achieve the effects of uniform flow field, increased length, and alleviation of flue gas temperature deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

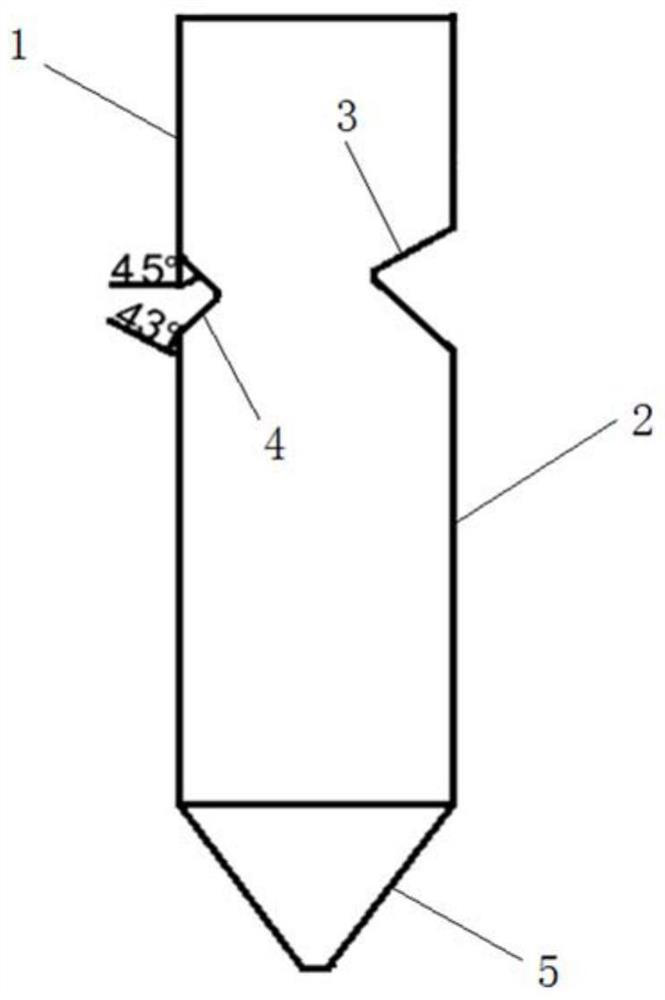

[0028] Such as figure 1 As shown, a new 700℃ ultra-supercritical π-type four-corner tangentially fired boiler structure includes a refraction angle 3 arranged on the back wall 2 and an inverted triangular arch angle 4 arranged on the front wall 1, and the inverted triangle arch angle 4 is set In the upper area of the boiler overfire air, it has a blocking effect on the rising flue gas of the furnace, and the upper part of the flame angle 3 is the furnace outlet. Among them, the height position of the inverted triangular arch angle 4 is lower than the height position of the flame bending angle 3, the longitudinal section of the inverted triangular arch angle 4 is a non-isosceles triangle structure, the inverted triangular arch angle 4 is recessed toward the interior of the furnace, and the inverted triangular arch angle The angle between the top of the angle 4 and the upper part of the boiler is greater than the angle between the bottom of the inverted triangular arch angle 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com