Cleaning cycle evaluation method, device and equipment for condensing lens field of photo-thermal power station

A technology of photothermal power stations and concentrators, applied in the field of solar energy applications, can solve problems affecting the energy conversion efficiency of the concentrator field, the decline in the average annual power generation of the unit, and the increase in the cost of electricity per unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

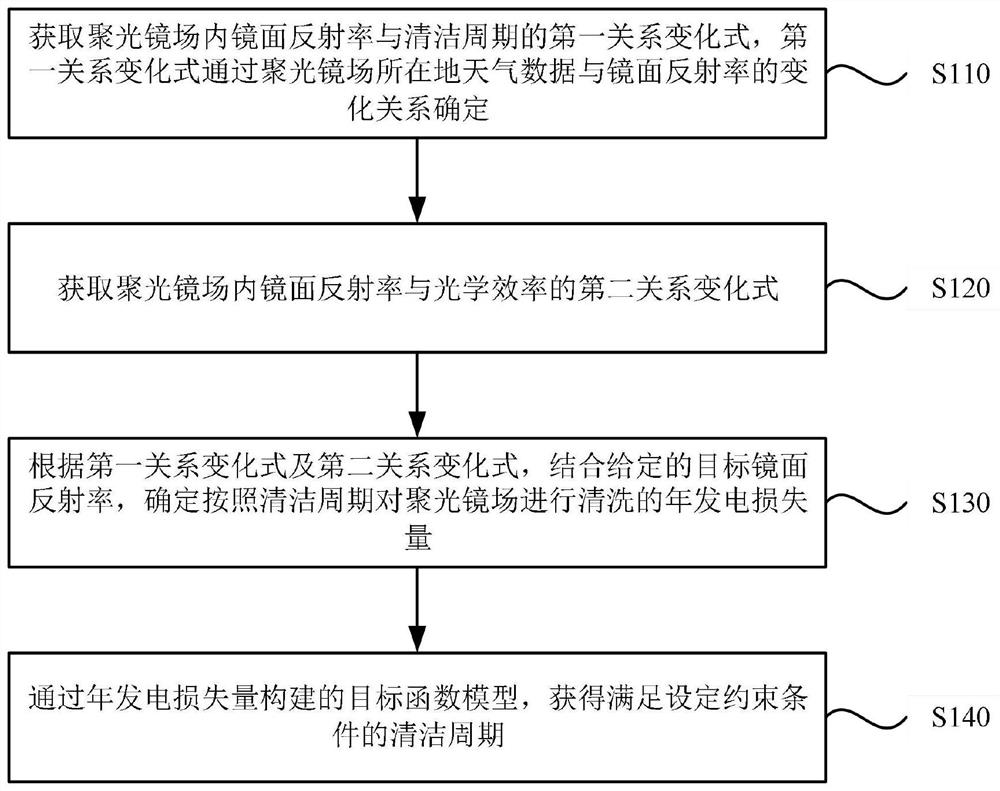

[0027] figure 1 It is a flow chart of a method for evaluating the cleaning cycle of the condenser field of a photothermal power station provided in Embodiment 1 of the present invention. This embodiment is applicable to the cleaning of the condenser field of a photothermal power station. To perform, the device may be implemented by software and / or hardware.

[0028] Such as figure 1 As shown, the method specifically includes the following steps:

[0029] S110. Acquire a first variation expression of the relationship between the mirror reflectance and the cleaning period in the condenser field, and the first relationship variation is determined by the change relationship between the weather data of the location of the condenser field and the mirror reflectivity.

[0030] Among them, the specular reflectance is a parameter of the ability of the specular reflection in the condenser field to reach the specular sunlight, and can be expressed by the ratio of the radiant flux refle...

Embodiment 2

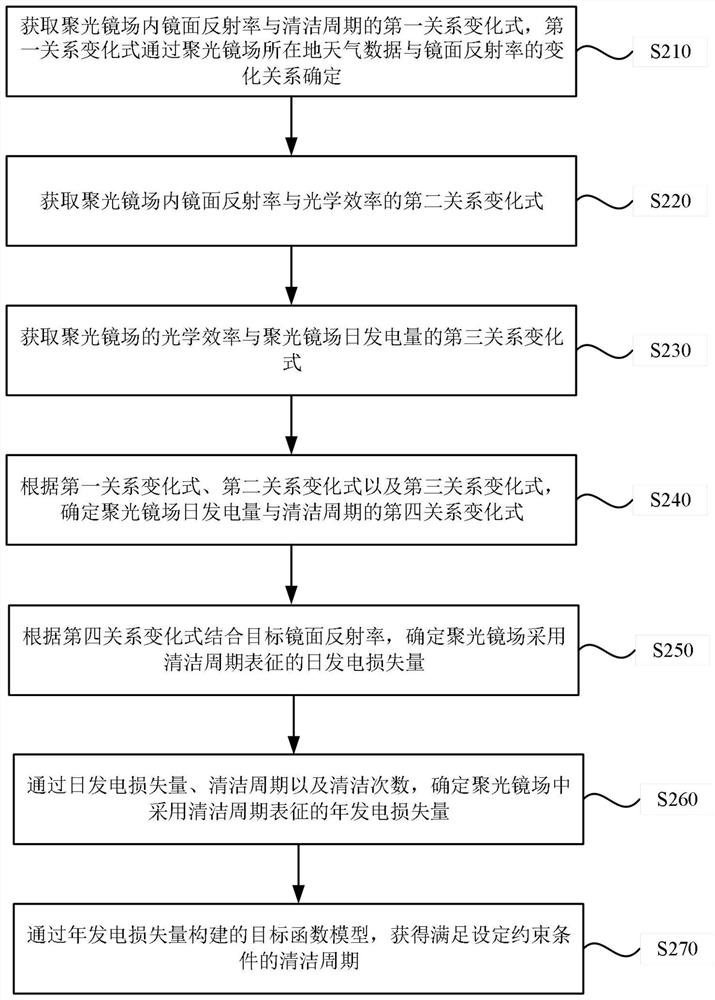

[0057] figure 2 It is a flow chart of a method for evaluating the cleaning cycle of the condenser field of a photothermal power plant provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further optimizes the cleaning cycle evaluation method for the condenser mirror field of the above-mentioned photothermal power station.

[0058] Such as figure 2 As shown, the method specifically includes:

[0059] S210. Obtain a first variation expression of the relationship between the reflectance of the mirror surface and the cleaning cycle in the condenser field, and the variation expression of the first relationship is determined by the change relationship between the weather data of the location of the condenser field and the reflection ratio of the mirror surface.

[0060] S220. Obtain a second variation formula of the relationship between the specular reflectance and the optical efficiency in the field of the condenser...

Embodiment 3

[0096] Figure 4 A structural block diagram of a cleaning cycle evaluation device for the condenser field of a photothermal power station provided in Embodiment 3 of the present invention, as shown in Figure 4 As shown, the device includes: a first relationship variation acquisition module 31 , a second relationship variation acquisition module 32 , an annual power generation loss determination module 33 and a cleaning cycle acquisition module 34 .

[0097] The first relationship variation acquisition module 31 is used to obtain the first relationship variation of the mirror reflectance and the cleaning cycle in the condenser field, and the first relationship variation is determined by the change relationship between the weather data of the condenser field and the specular reflectivity;

[0098] The second relationship variation acquisition module 32 is used to obtain the second relationship variation of the specular reflectance and optical efficiency in the field of the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com