Planar transformer

A planar transformer and transformer technology, applied in the field of transformers, can solve the problems of high-frequency transformers such as low drop resistance, troublesome winding process, and limited efficiency, and achieve the effects of improving service life, high quality requirements, and improving drop resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

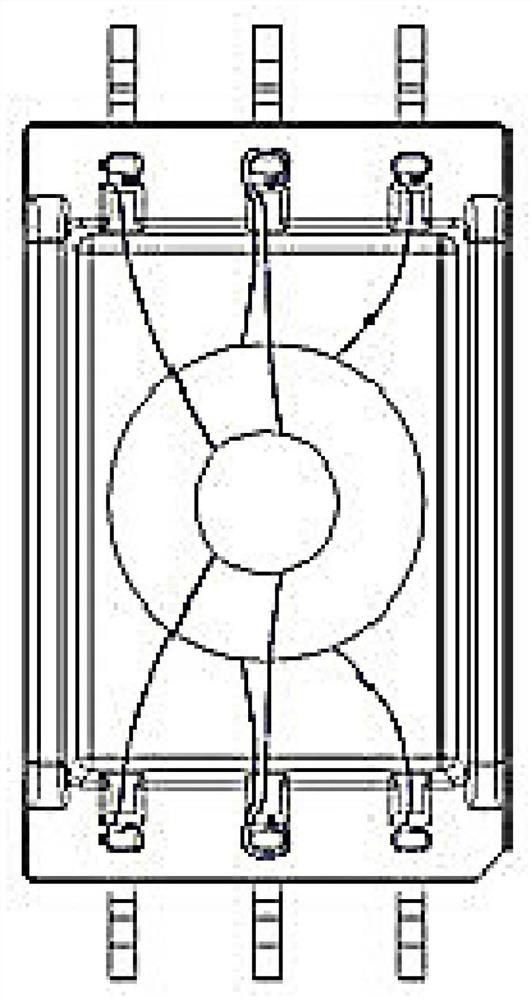

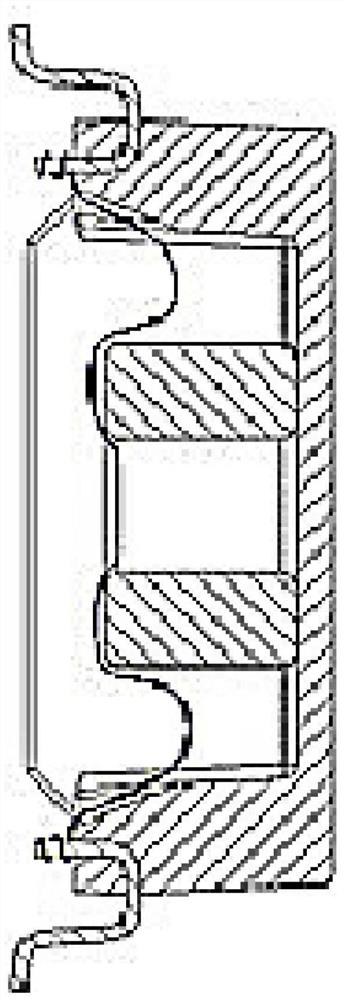

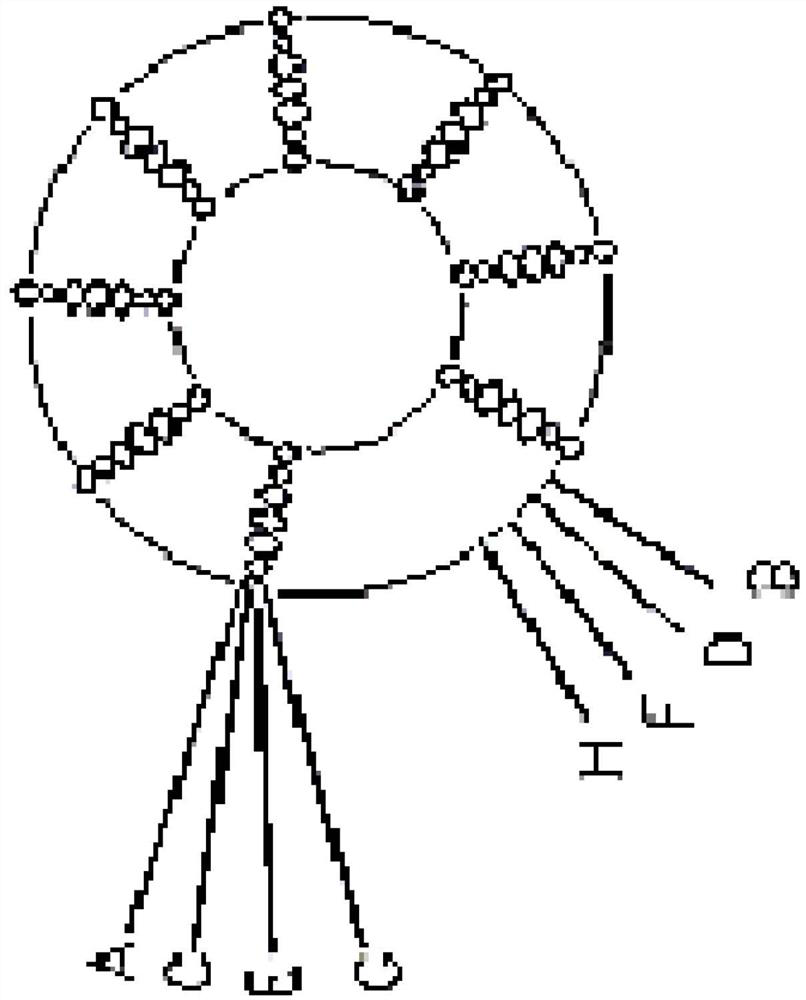

[0046] Please refer to Figure 1 to Figure 15 As shown, it shows the specific structure of various preferred embodiments of the present invention, including a PCB wire package 10, and the PCB wire package 10 has a first PCB integrated board 11 and a second PCB integrated board that are stacked and connected. 12. The first PCB integrated board 11 and the second PCB integrated board 12 both include a 4N layer PCB coil 20 and a 4N-1 layer PCB substrate 30 stacked up and down, and the N is an integer greater than or equal to 1; Each layer of PCB substrate 30 in the first PCB integrated board 11 and the second PCB integrated board 12 is separated between two adjacent layers of PCB coils 20, and the PCB coil 20 is printed on the PCB substrate 30 in a spiral shape. superior;

[0047] The two ends of the first PCB integrated board 11 and the second PCB integrated board 12 are correspondingly provided with three first through holes 101, and the middle is correspondingly provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com