All-terrain telescopic rotary blade and using method thereof

An all-terrain and rotary tiller blade technology, applied in the field of rotary tiller, can solve the troublesome and inconvenient cleaning of the rotary tiller, and the inability of the rotary tiller to expand and contract elastically, so as to improve the effect of rotary tillage and avoid collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

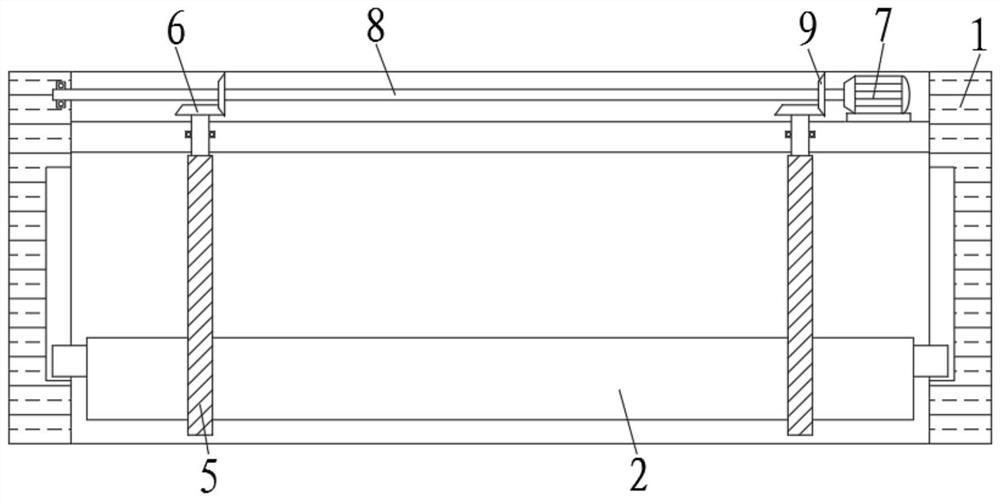

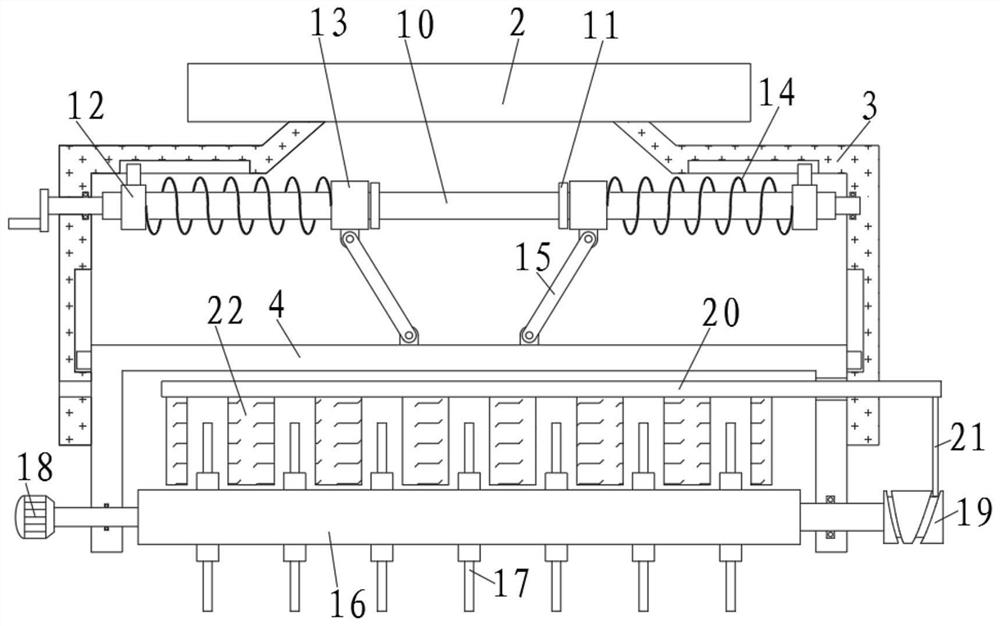

[0045] The all-terrain telescopic rotary tiller includes a mounting frame 1, a fixed plate 2 is slidably connected to the mounting frame 1, and a fixed frame 3 is fixedly installed on the bottom of the fixed plate 2 away from the mounting frame 1, and a knife frame 4 is slidably connected to the fixed frame 3 , and the cutter shaft 16 is rotatably connected to the tool holder 4, a second motor 18 is installed on one side of the tool holder 4, and the output end of the second motor 18 is connected with the cutter shaft 16, and a plurality of sets of blades are fixedly arranged on the outer side of the cutter shaft 16 17. A lifting mechanism is provided in the installation frame 1, and the lifting mechanism includes a threaded rod 5, a large bevel gear 6, a first motor 7, a cross bar 8, and a small bevel gear 9;

[0046] Two sets of threaded rods 5 are rotatably connected to the mounting frame 1, and the top of the threaded rods 5 is fixedly provided with a large bevel gear 6, th...

Embodiment 2

[0059] On the basis of embodiment 1,

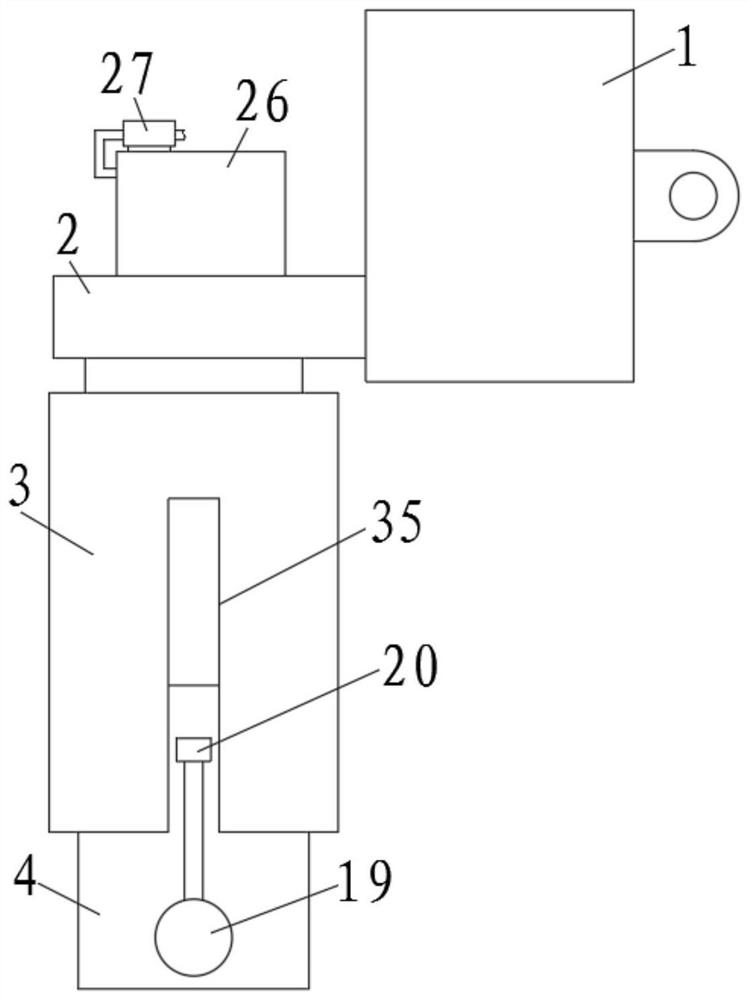

[0060] A cutting mechanism matched with the blade 17 is also provided in the knife rest 4, and the cutting mechanism includes a cylindrical cam 19, a horizontal plate 20, a vertical bar 21, and a cutting knife 22;

[0061] One end of the knife shaft 16 extends out of the knife rest 4 and is fixedly connected with a columnar cam 19, and the inner top of the knife rest 4 is slidably connected with a horizontal plate 20, and the horizontal plate 20 extends out of the knife rest 4 and is fixedly provided with a vertical bar that matches the cylindrical cam 19. 21, and a plurality of groups of cutting knives 22 are fixedly arranged at the bottom of the horizontal plate 20.

[0062] One side of the fixing frame 3 is provided with a through groove 35 matching with the horizontal plate 20 , and gaps matching with the blades 17 are formed between the groups of cutting knives 22 .

[0063] The method of use of the present invention also includes: ...

Embodiment 3

[0065] On the basis of embodiment 2,

[0066] Both sides of the fixed frame 3 are also provided with a supporting mechanism, and the supporting mechanism includes a cylinder 28, a connecting plate 29, a connecting rod 30, a supporting rod 31, and a roller 32;

[0067] Cylinders 28 are installed on both sides of the fixed frame 3, and the output end of the cylinder 28 is fixedly provided with a connecting plate 29, the bottom two sides of the connecting plate 29 are rotatably connected with connecting rods 30, and the other ends of the connecting rods 30 are rotatably connected with support rods 31 , the support rod 31 is rotatably connected with the fixed frame 3 , and the bottom of the support rod 31 is provided with a roller 32 .

[0068] The method of use of the present invention also includes: when the device needs to move, start the cylinder 28, and the cylinder 28 drives the connecting rod 30 to rotate through the connecting plate 29. Since the supporting rod 31 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com