Method for preparing preservative-free fruit and vegetable sauce by microbial fermentation method

A technology of microbial fermentation and zero preservatives, applied in the field of fruit and vegetable sauce processing, can solve the problems of easy-to-contaminate bacteria, short storage period, bad smell, etc., and achieve the effect of enriching nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

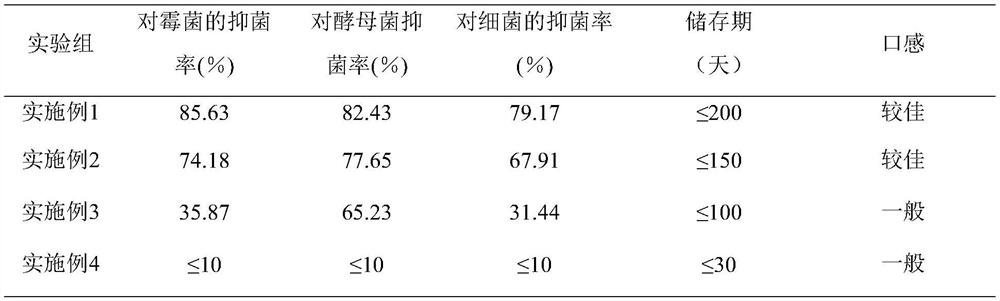

Embodiment 1

[0035] The present embodiment provides the method for making zero-preservative fruit and vegetable sauce by microbial fermentation, and the specific steps are as follows:

[0036] Step 1: Selection of raw materials: select fresh, non-rotten and non-worm-eaten fruits and vegetables, soak them in salt water for 20 minutes, rinse them, and drain the water;

[0037] Step 2: beating and concentration: After beating the fruit and vegetable raw materials, concentrate 4 to 5 times to obtain concentrated fruit and vegetable pulp, then add appropriate amount of white sugar and maltose to mix;

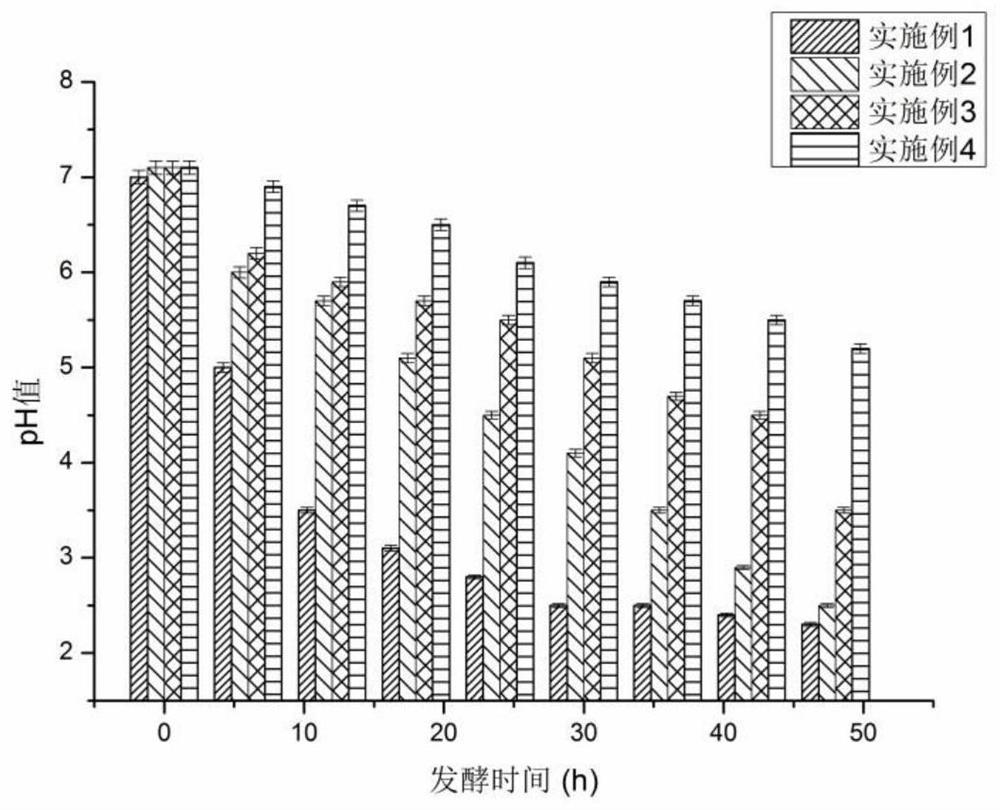

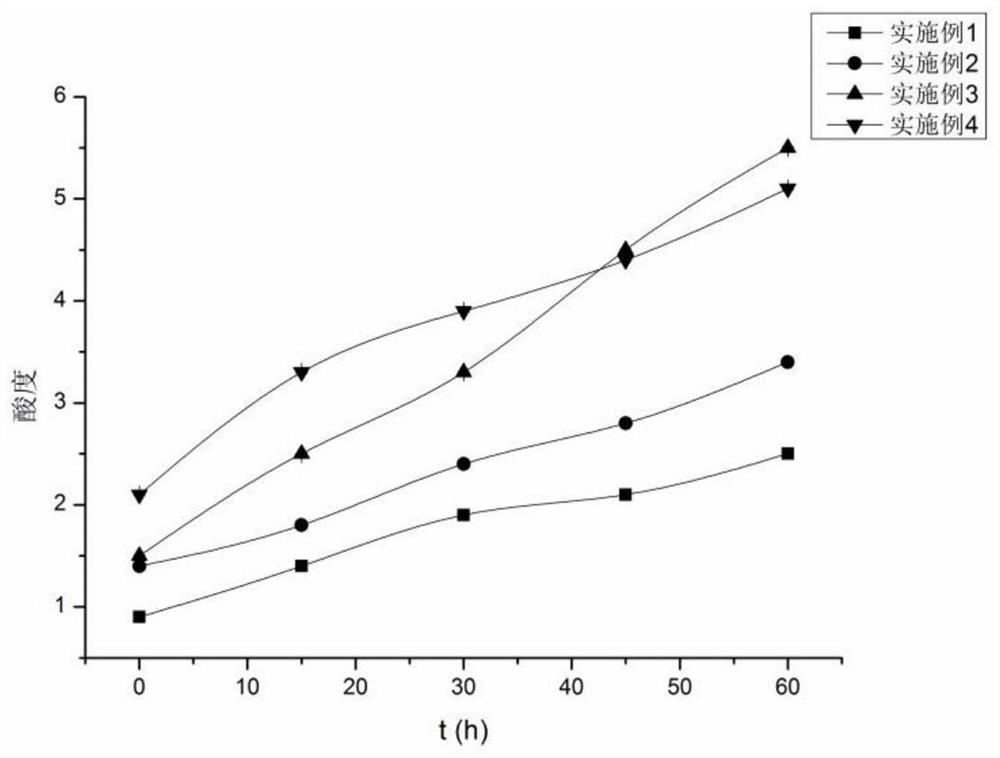

[0038] Step 3: Microbial fermentation: Add 0.03% direct-throwing starter (Lactobacillus plantarum: Leuconostoc enterococcus = 2:1) and 5% salt in cold boiling water, ferment at (30±2)°C for 24-36 hours, and the pH value reaches At 4.0, adjust the temperature to (17±2)°C to continue fermentation, and end the fermentation when the pH value reaches (2.2±0.2);

[0039] Step 4: UHT instantaneous ster...

Embodiment 2

[0052] The present embodiment provides the method for making zero-preservative fruit and vegetable sauce by microbial fermentation, and the specific steps are as follows:

[0053] Step 1: Selection of raw materials: select fresh, non-rotten and non-worm-eaten fruits and vegetables, soak them in salt water for 20 minutes, rinse them, and drain the water;

[0054] Step 2: beating and concentration: After beating the fruit and vegetable raw materials, concentrate 4 to 5 times to obtain concentrated fruit and vegetable pulp, then add appropriate amount of white sugar and maltose to mix;

[0055] Step 3: Microbial fermentation: add 3% fermentation broth (Lactobacillus plantarum: Leuconostoc enterococcus = 2:1) and 5% salt in cold boiling water, ferment at (30±2)°C for 24-36 hours, and adjust when the pH value reaches 4.0 Continue the fermentation when the temperature reaches (17±2)°C, and end the fermentation when the pH value reaches (2.2±0.2);

[0056] Step 4: UHT instantaneous ...

Embodiment 3

[0065] The present embodiment provides the method for making zero-preservative fruit and vegetable sauce by microbial fermentation, and the specific steps are as follows:

[0066] Step 1: Selection of raw materials: select fresh, non-rotten and non-worm-eaten fruits and vegetables, soak them in salt water for 20 minutes, rinse them, and drain the water;

[0067] Step 2: beating and concentration: After beating the fruit and vegetable raw materials, concentrate 4 to 5 times to obtain concentrated fruit and vegetable pulp, then add appropriate amount of white sugar and maltose to mix;

[0068] Step 3: Microbial fermentation: add 3% lactic acid bacteria starter and 5% salt cold boiling water, ferment at (30±2)°C for 24 to 36 hours, adjust the temperature to (17±2)°C when the pH value reaches 4.0 and continue fermentation, and the pH value reaches (2.2 ± 0.2) when the end of fermentation;

[0069] Step 4: UHT instantaneous sterilization;

[0070] Step 5: Aseptic filling: Fill th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com