Multi-bar-code efficient automatic acquisition system and method

A collection system and collection method technology, applied in the field of barcode scanning, can solve problems such as easy to cause after-sales complaints, high repair rate, record data errors, etc., to reduce the repair rate and after-sales complaint rate, eliminate product quality problems, and miniaturize the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

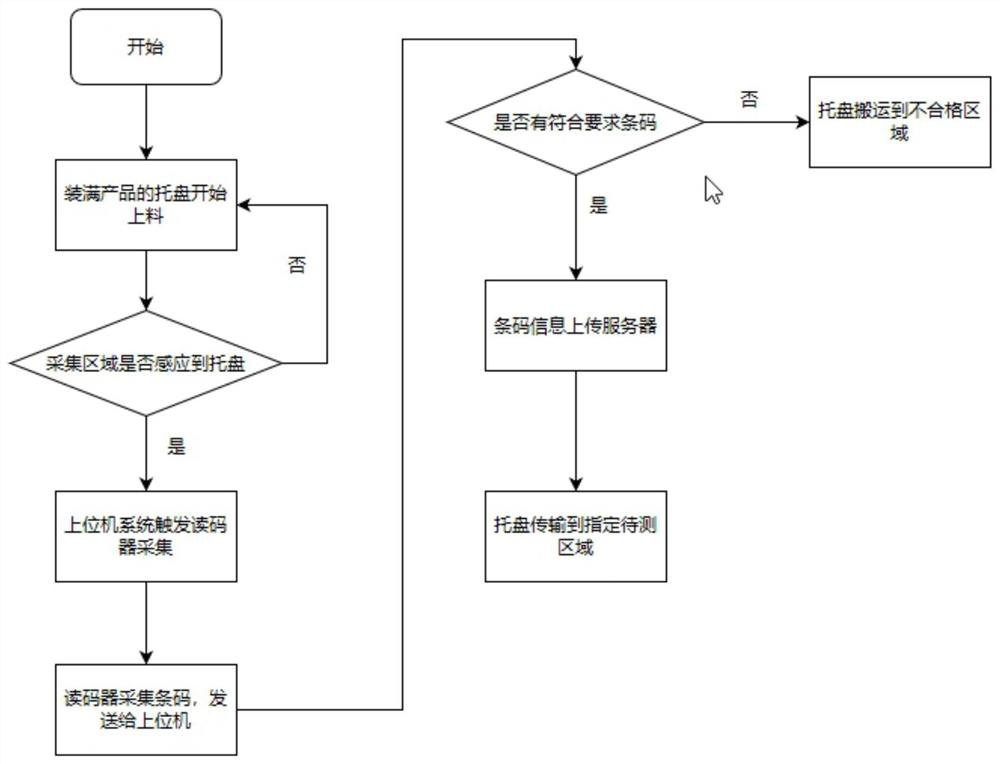

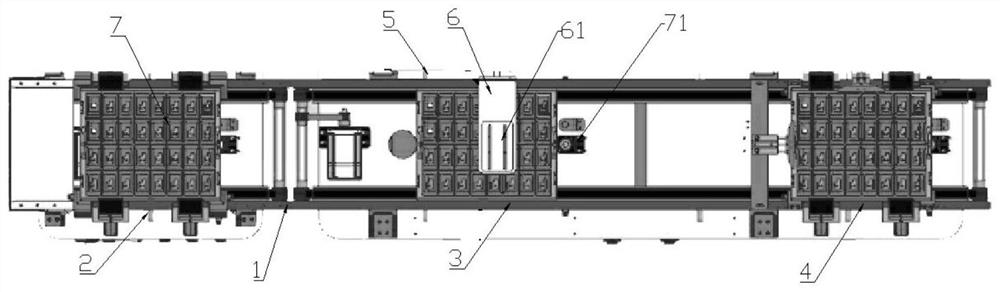

[0055] Embodiment: a kind of multi-barcode efficient automatic collection method comprises the following steps:

[0056] (1) Place the WIFI module on the pallet, and put the pallet on the feeding area of the conveyor belt;

[0057] (2) Start the conveyor belt, and transfer the tray carrying the WIFI module to the collection area;

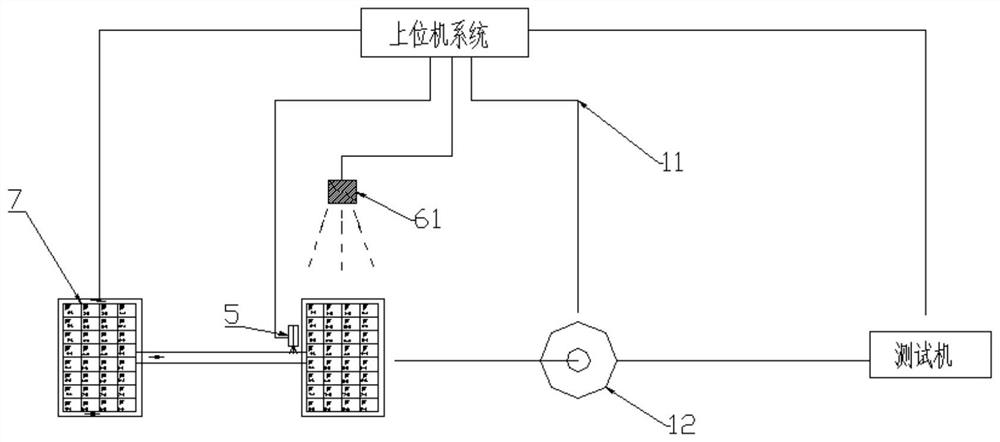

[0058] (3) The sensor detects that the pallet enters the scanning area, and the PLC control system sends the sensing signal and the status signal of the conveyor belt to the host computer;

[0059] (4) The upper computer sends a start collection command to control the code reader to collect the barcode information of the WIFI module;

[0060] (5) The code reader sends the barcode information to the host computer according to the protocol format. The host computer judges whether the WIFI module is placed correctly and whether the pasted barcode is correct according to the appearance characteristics of the barcode. The standard that meets the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com