Construction method applied to gently-inclined ore body cemented filling strip stoping

A technology of cemented filling and construction methods, which is applied in the direction of filling, ground mining, mining equipment, etc., and can solve the problems of large roof safety and blasting risks, susceptibility to changes in ground pressure, and large roof exposure area, etc., to reduce the roof The effect of reducing the risk of falling, reducing the safety risk of the roof and shortening the recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

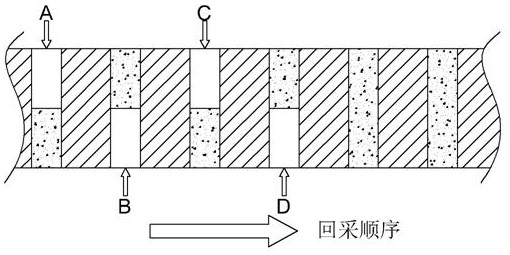

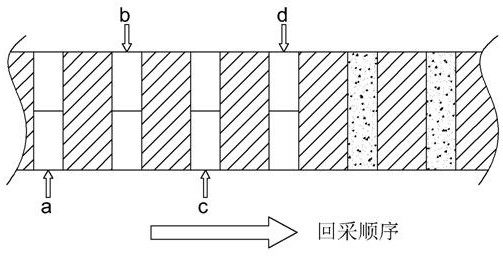

[0044] Example 1 as figure 1 and figure 2 As shown, a construction method applied to the mining of gently inclined ore body cemented filling strips includes the following steps:

[0045] Step 1: Analyze the construction safety conditions of the mining area structure, and draw up the construction plan and technological process; the safety condition analysis includes lithological stability analysis, rockburst possibility analysis and hydrogeological condition analysis, which is convenient for setting the plan, and the most important thing is to ensure that the construction process To ensure the safety of the roof, ensure the safety monitoring of the roof to ensure that there is no water leakage on the roof during the cemented filling period, and no geological water hazards occur in the area.

[0046] Step 2: Divide the mining area and determine the arrangement of roadways and strips. The strips located in the same mining area are arranged at equal intervals between the roadway...

Embodiment 2

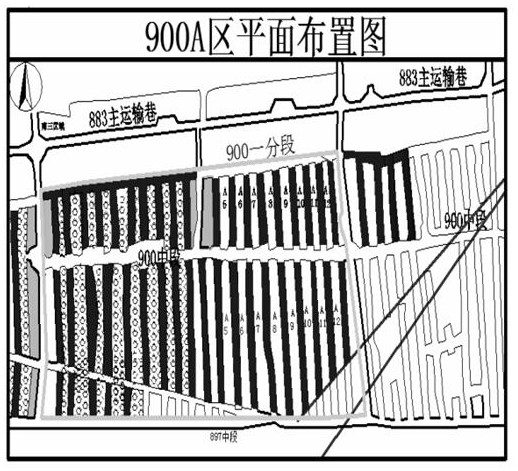

[0054] Example 2 as image 3 As shown, the azimuth descriptions of southeast, northwest and north correspond one-to-one with the up, down, left, and right in the figure, up corresponds to north, and left corresponds to west, where:

[0055] Roadway floor elevation: +888 to +902 meters; the surface elevation of the overlying strata +1158 to +1164 meters; the minimum thickness of the overlying strata is 270 meters, the texture structure is simple, and it is a monoclinic structure, dipping north-northeast, with a dip angle of 4-7°, and partially affected by faults and cracks, the roof structure is relatively stable, and there are rockbursts locally.

[0056] 1. Roadway Excavation Section Requirements

[0057] Rectangular section, the excavation width is 6 meters, and the height is based on the thickness of the ore seam. The control height of the full-layer excavation is 3.5 meters, and the thickness of the rich ore is less than 3.5 meters. Layer excavation.

[0058] 2. Roadway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com