Alternating-current zero-crossing action non-arc switch and working method thereof

A switching and zero-crossing technology, applied in magnetic switches, electric switches, magnetic field/electric field switches, etc., can solve problems such as affecting operational reliability and personal safety, SF6 switches do not meet environmental protection requirements, and are not suitable for smart grid construction. Achieve the effect of eliminating arcing phenomenon, solving environmental protection problems and reducing installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In order to realize the action of the switch at the zero crossing of the AC, a fast switch is first required. If the switch is too slow (for example, more than 10ms), the action at the zero crossing cannot be realized. In addition, the action time of the switch must be stable. If it is unstable, it cannot be realized every time. Can accurately move at zero crossing.

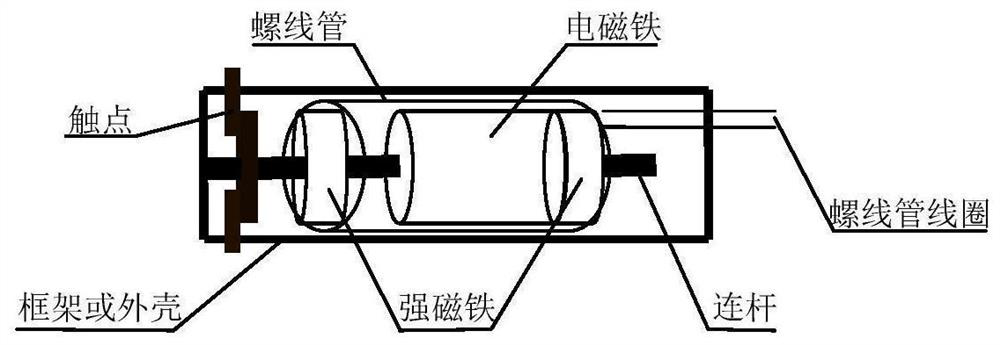

[0041] A push-pull piston type high-speed switch with Ni-Fe-B strong magnet as the piston, such as figure 1 As shown, including two RuFeB strong magnets, an electromagnet, a solenoid, and the main contact, the two RuFeB magnets include the first RuFeB strong magnet and the second RuFeB strong magnet; two RuFeB strong magnets; The iron-boron strong magnet and the electromagnet are set in the solenoid, and the electromagnet is located between two Ru-Fe-B strong magnets. The two Ru-Fe-B strong magnets installed with opposite polarities are used as pistons and driven by the solenoid. A push-pull (push-pull) ...

Embodiment 2

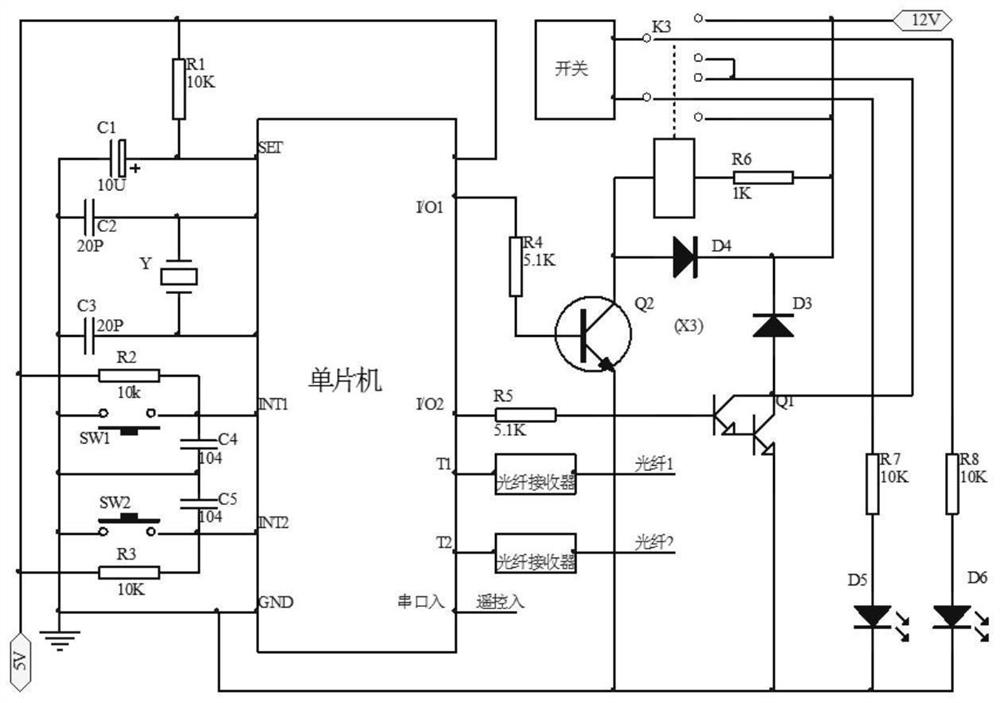

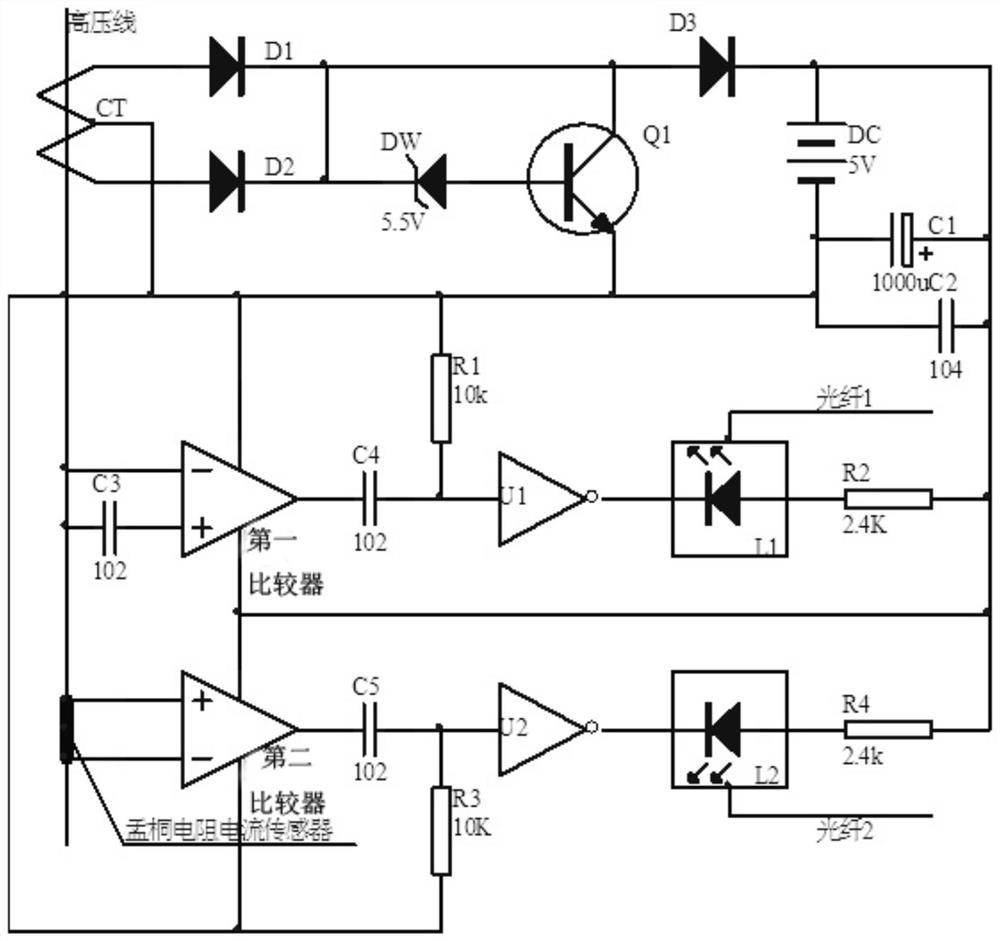

[0047] According to the Ni-Fe-B push-pull piston high-speed switch described in Embodiment 1, the difference is that: the intelligent monitoring circuit of the Ru-Fe-B push-pull piston high-speed switch includes a medium-high voltage zero-crossing phase detection circuit and an intelligent drive circuit;

[0048] The zero-crossing pulse generated by the phase zero-crossing detection circuit, the voltage is transmitted to T1 and T2 of the single-chip microcomputer through the first optical fiber (fiber 1) and the current through the second optical fiber (fiber 2) for periodic testing, and the single-chip microcomputer receives the action command or manual operation Enter the interrupt service program after the command, the interrupt service program first determines the current direction of the compass coil through the current reversing relay K3 according to the command (on, off), and then waits for the driving pulse. When the voltage or current crosses zero next time, the driving...

Embodiment 3

[0062] The working method of the NiFeB push-pull piston type high-speed switch described in embodiment 2 comprises steps as follows:

[0063] (1) The voltage phase zero-crossing pulse and current phase zero-crossing pulse generated by the voltage phase sensor and the current phase sensor (which can be taken directly from the low-voltage power grid) are sent to the The timer T1 and the timer T2 of the single-chip microcomputer carry out cycle measurement, and when the single-chip microcomputer receives an action instruction or manual control, enter step (2) interrupt service program;

[0064] (2) The time data of the previous half cycle shall prevail. When the first half cycle crosses zero again, the delay will start. When the delay time is the time of the first half cycle minus half of the switching action time, the output drive spiral will start. The pulse of the tube makes the action time fall exactly at the second zero-crossing position. When the command received is to turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com