Split-ring resonator-like electromagnetic shielding multilayer composite fabric and preparation method thereof

A split resonant ring, electromagnetic shielding technology, applied in the fields of magnetic/electric field shielding, electrical components, antennas, etc., can solve the problems of reduced shielding performance of fabrics, adverse effects on human body and instruments, etc., to achieve improved shielding effectiveness, good shielding effectiveness, reduced leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

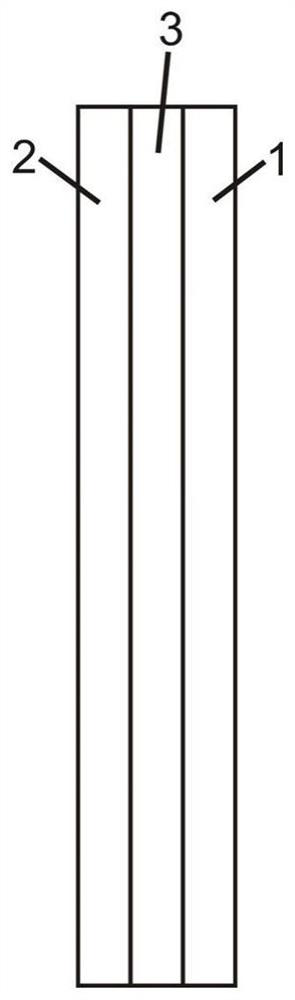

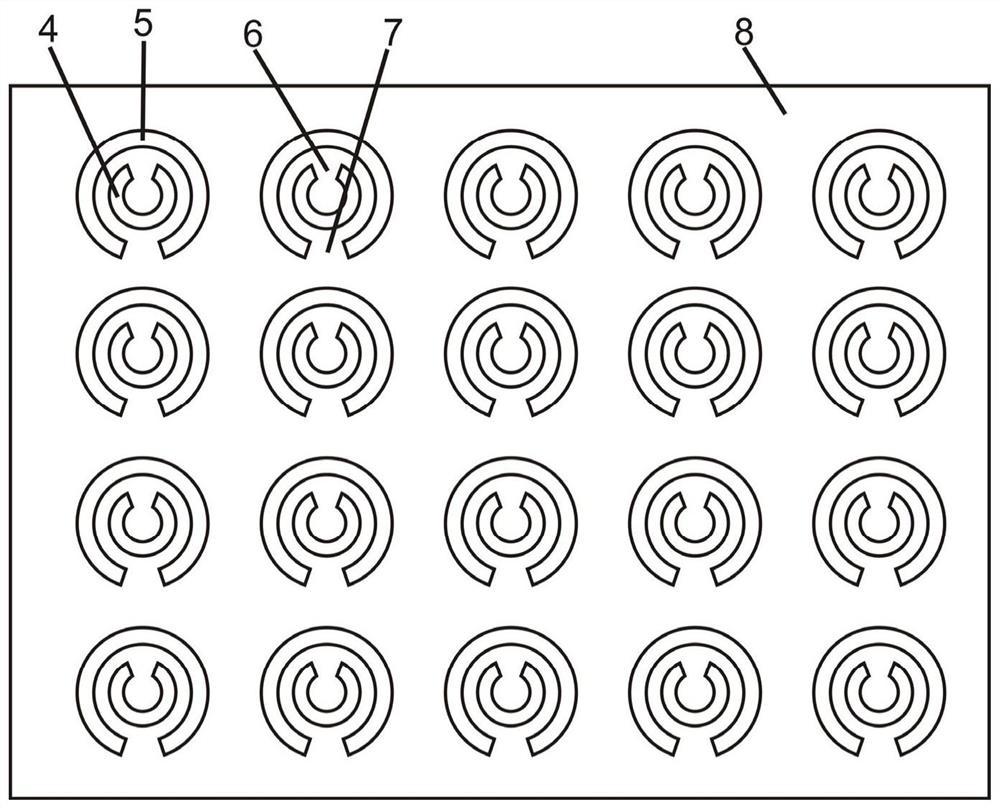

[0042] The present invention is a kind of open-ended resonant ring electromagnetic shielding multi-layer composite fabric, its structure is as follows figure 1 As shown, it includes a front layer 1, at least one middle absorbing layer 3 and a back layer 2 which are sequentially connected by bonding, the front layer 1 is an electromagnetic wave incident layer, the back layer 2 is an electromagnetic wave reflection layer, and the middle absorbing layer 3 has multiple The frequency band electromagnetic wave absorption function and the electromagnetic wave reflectivity is greater than -5dB, such as figure 2 As shown, the middle absorbing layer 3 is formed by arranging a plurality of split resonant rings 8 , and the plurality of split resonant rings 8 are adhered between the front layer 1 and the back layer 2 by bonding.

[0043] The front layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com